Dec . 16, 2024 07:32 Back to list

Top Manufacturers of Pigment Grade Lithopone for Diverse Applications

The Role of Pigment Lithopone in the Manufacturing Industry

Lithopone, a versatile pigment, has been a staple in industries ranging from coatings and plastics to paper and rubber. Composed primarily of barium sulfate and zinc sulfide, lithopone is prized for its excellent whiteness, opacity, and durability. The pigment is produced through a complex chemical process, making the role of lithopone manufacturers pivotal in the supply chain of various products that require high-quality pigmentation.

Understanding Lithopone

Lithopone comes in various formulations, typically containing 30% to 70% pigment content, depending on the specific application requirements. The most common grades include lithopone 28, lithopone 30, and lithopone 50, with differing amounts of zinc sulfide and barium sulfate. Pigment lithopone is non-toxic and provides good thermal stability as well as resistance to fading, making it suitable for use in outdoor applications.

Its high opacity allows for excellent coverage, which is particularly valuable in paints and coatings. As the demand for environmentally friendly products grows, manufacturers are increasingly turning to lithopone, which does not contain harmful components such as lead or cadmium, offering a safer alternative to traditional pigments.

Manufacturing Process

The production of lithopone involves several stages, starting with the precipitation of zinc sulfide and barium sulfate. Typically, the process begins with the reaction of sulfuric acid with zinc oxide to produce zinc sulfate. This is then mixed with barium sulfide under controlled conditions to create the desired lithopone pigment. After precipitation, the product is filtered, washed, and dried before being milled to the required fineness.

Manufacturers focus on adhering to stringent quality control measures throughout the production process. This ensures a consistent particle size, brightness, and stability of the pigment, essential attributes that end-users expect from high-quality lithopone.

The Market for Pigment Lithopone

pigment lithopone manufacturers

As industries evolve, the demand for lithopone pigments is on the rise. The global shift towards sustainable practices is driving this growth, particularly in the paint and coatings sector, where environmental regulations are becoming increasingly stringent. Consumers now favor products that minimize environmental impact, which promotes the use of non-toxic pigments like lithopone.

In addition to paints, lithopone plays a significant role in the plastic and rubber industries, where it serves not only as a pigment but also as a filler

. Its incorporation enhances the performance characteristics of these materials, increasing durability and improving aesthetic appeal.Therefore, lithopone manufacturers are strategically positioned within the market to cater to this growing need. By investing in research and development, these manufacturers can develop new formulations and enhance existing products to meet evolving consumer preferences.

Challenges Faced by Manufacturers

Despite its advantages, lithopone manufacturers face several challenges in the industry. One of the major concerns is the fluctuating prices of raw materials. As the costs of zinc and barium continue to rise, manufacturers must find ways to maintain profitability without compromising the quality of their products.

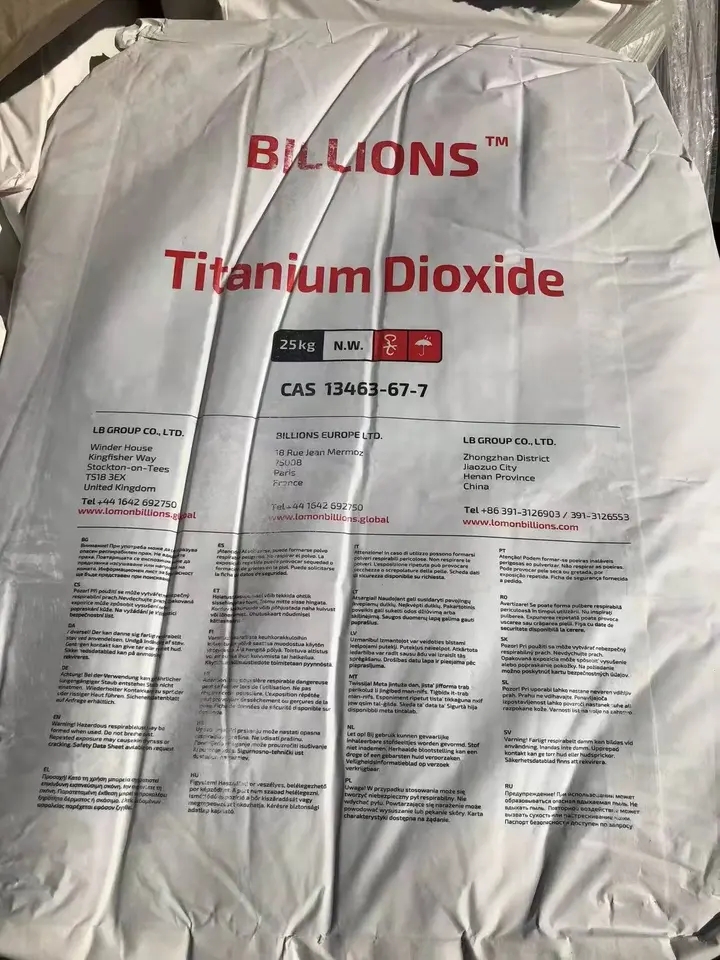

Another issue is competition from alternative pigments. While lithopone is a preferred option for many applications, substitutes like titanium dioxide offer comparable performance features. Therefore, manufacturers need to emphasize the unique benefits of lithopone, such as its safety profile and eco-friendliness, to retain market share.

Conclusion

Pigment lithopone is an essential component in multiple industries, valued for its excellent properties and safety. As manufacturers continue to innovate and adapt to market demands, lithopone will likely remain a key player in the pigments market. With the continual push towards sustainability, the future of lithopone appears bright. Manufacturers who can navigate raw material challenges while delivering high-quality pigments will secure their position as leaders in the industry. Whether for paints, plastics, or beyond, lithopone stands as a testament to how traditional materials can evolve and remain relevant in a rapidly changing world.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025