Dec . 10, 2024 03:41 Back to list

Top Manufacturers of Lithopone Pigments for Various Applications

Pigment Lithopone Manufacturers An Overview of the Industry

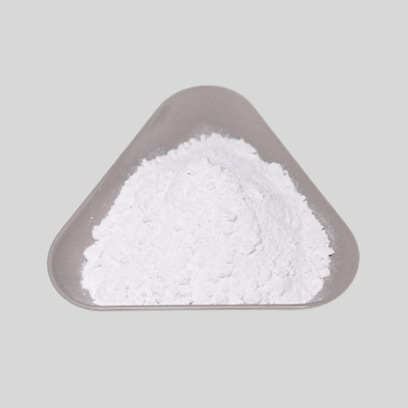

Pigment lithopone is a white pigment that is renowned for its excellent opacity, durability, and weather resistance. Widely used in paints, coatings, plastics, and various other products, lithopone is a critical component in achieving vibrant and long-lasting colors in numerous applications. The manufacturing process of pigment lithopone involves the precise combination of zinc sulfide and barium sulfate, resulting in a product that offers superior performance characteristics compared to other white pigments.

Manufacturing Processes

Lithopone is typically produced through two methods the precipitation method and the co-precipitation method. In the precipitation method, barium sulfide is reacted with zinc sulfate to form the pigments, which are then filtered, washed, and dried. The co-precipitation method, on the other hand, involves the simultaneous precipitation of both zinc sulfide and barium sulfate in a single process, offering a more efficient production route that can reduce costs and resource consumption.

Key Players in the Industry

The pigment lithopone market is characterized by several key manufacturers, each vying to capture market share through innovative products and processes. Companies such as BASF, Huntsman, and Tronox are among the top players, known for their commitment to quality and environmental sustainability. These manufacturers invest heavily in research and development to enhance product performance, reduce production costs, and minimize environmental impact.

Global Demand and Market Trends

pigment lithopone manufacturers

The demand for lithopone pigment is influenced by various factors, including the growth of the construction and automotive industries, which require high-quality coatings and finishes. As these sectors expand, so too does the demand for durable and aesthetically pleasing materials. Moreover, with an increasing focus on sustainable practices and regulations, manufacturers are exploring eco-friendly alternatives and innovations, such as water-based coatings that incorporate lithopone for reduced VOC emissions.

Geographically, Asia-Pacific is the leading region for lithopone production and consumption, driven by rapid industrialization, urbanization, and a burgeoning consumer base. Countries like China and India are at the forefront, with numerous manufacturing plants catering to both local and international markets. As these regions continue to develop, the demand for high-performance pigments like lithopone is expected to rise.

Challenges in the Industry

While the future looks promising for lithopone manufacturers, several challenges remain. Fluctuations in raw material prices, environmental regulations, and the need for continuous innovation in the face of competition can pose significant challenges. Manufacturers must navigate these obstacles while ensuring compliance with environmental standards and adapting to changing consumer preferences.

Additionally, the industry faces competition from alternative white pigments, such as titanium dioxide, which is widely used due to its superior brightness and opacity. As the demand for eco-friendly solutions grows, manufacturers of lithopone must work to highlight the unique benefits of their products, such as lower production costs and reduced environmental impact.

Conclusion

Pigment lithopone is a vital component in the pigment industry, offering unique properties that make it suitable for a wide range of applications. With key manufacturers continuously innovating and adapting to market demands, the future of lithopone manufacturing appears bright. By emphasizing quality, sustainability, and performance, these companies are well-positioned to thrive in an increasingly competitive landscape. As the market evolves, embracing new technologies and responding to consumer needs will be crucial for maintaining a competitive edge. The pigment lithopone industry will undoubtedly continue to play a significant role in various sectors, paving the way for advancements in color technology and materials science.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025