Aug . 17, 2024 07:19 Back to list

Microbar Production and Innovation in Titanium Dioxide Manufacturing Techniques and Facilities

The Rise of Microbar Titanium Dioxide Factories A New Era in Pigment Production

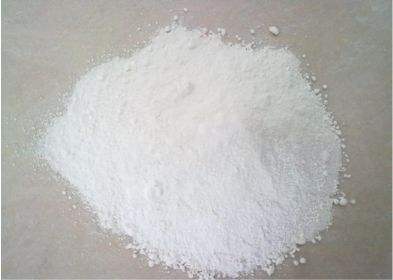

In recent years, the demand for high-quality pigments has skyrocketed due to the growing needs of various industries such as paints, coatings, plastics, and cosmetics. Among these pigments, titanium dioxide (TiO2) has emerged as the star performer, prized for its excellent opacity, brightness, and UV resistance. With the industry evolving, the advent of microbar titanium dioxide factories is setting new standards in production efficiency, sustainability, and product quality.

What is Microbar Titanium Dioxide?

Microbar titanium dioxide refers to a specific form and processing technique of titanium dioxide that results in a finer, more controlled particle size. This technology allows manufacturers to produce titanium dioxide with unique properties that cater to the evolving needs of various applications. The microbar format ensures enhanced dispersion in formulations, leading to better performance in end products.

Technological Advances in Production

The shift towards microbar titanium dioxide factories is largely driven by advancements in processing technologies. Traditional titanium dioxide production methods often result in large agglomerates, which can negatively affect the performance of the pigment in applications. Microbar factories utilize state-of-the-art milling and surface treatment processes that break down these aggregates, resulting in a more uniform particle size distribution. This innovation not only enhances the pigment's effectiveness but also improves the durability and aesthetics of products in which it is used.

Sustainability and Environmental Considerations

As industries face increasing pressure to adopt sustainable practices, microbar titanium dioxide factories are leading the way in environmentally responsible production. Many of these facilities are designed to minimize energy consumption and waste generation. Innovations in production processes can often achieve similar or superior performance levels while using fewer resources. Furthermore, some manufacturers are exploring the use of recycled materials and renewable energy sources to power their operations.

microbar titanium dioxide factories

By prioritizing eco-friendly methods, these factories are not only aligning themselves with global sustainability goals but also appealing to a growing market of environmentally conscious consumers. The integration of life cycle assessment in the production process ensures that the environmental impact of titanium dioxide is continuously monitored and mitigated.

Market Expansion and Economic Implications

With the growth of microbar titanium dioxide factories, the global titanium dioxide market is expected to expand significantly. This is driven by factors such as the increasing demand in emerging economies, where construction and automotive industries are booming. As these sectors grow, the need for high-performance pigments will only escalate.

Furthermore, by investing in microbar technology, manufacturers can differentiate their products in a competitive marketplace. This innovation can provide them with a unique selling proposition that attracts customers looking for quality and performance. As a result, businesses that adopt this technology may experience increased profitability and market share.

Challenges and Future Outlook

Despite the advantages of microbar titanium dioxide factories, challenges remain. The initial investment in advanced technology can be substantial, and smaller manufacturers may struggle to adapt. Additionally, the volatility in raw material prices can impact profitability. However, as the technology matures and becomes more widely adopted, costs are likely to decrease, making it more accessible to a broader range of manufacturers.

In conclusion, microbar titanium dioxide factories represent a significant advancement in the realm of pigment production. With their focus on technology, sustainability, and market adaptability, these facilities are not only meeting the demands of today’s industries but also paving the way for a more sustainable future in pigment manufacturing. The evolution of titanium dioxide production is a testament to the ongoing innovation in materials science, highlighting the significant role these factories will play in shaping the future of various industrial applications.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025