Dec . 01, 2024 16:43 Back to list

lithopone zns-baso4 quotes

Understanding Lithopone and Its Components ZnS and BaSO4

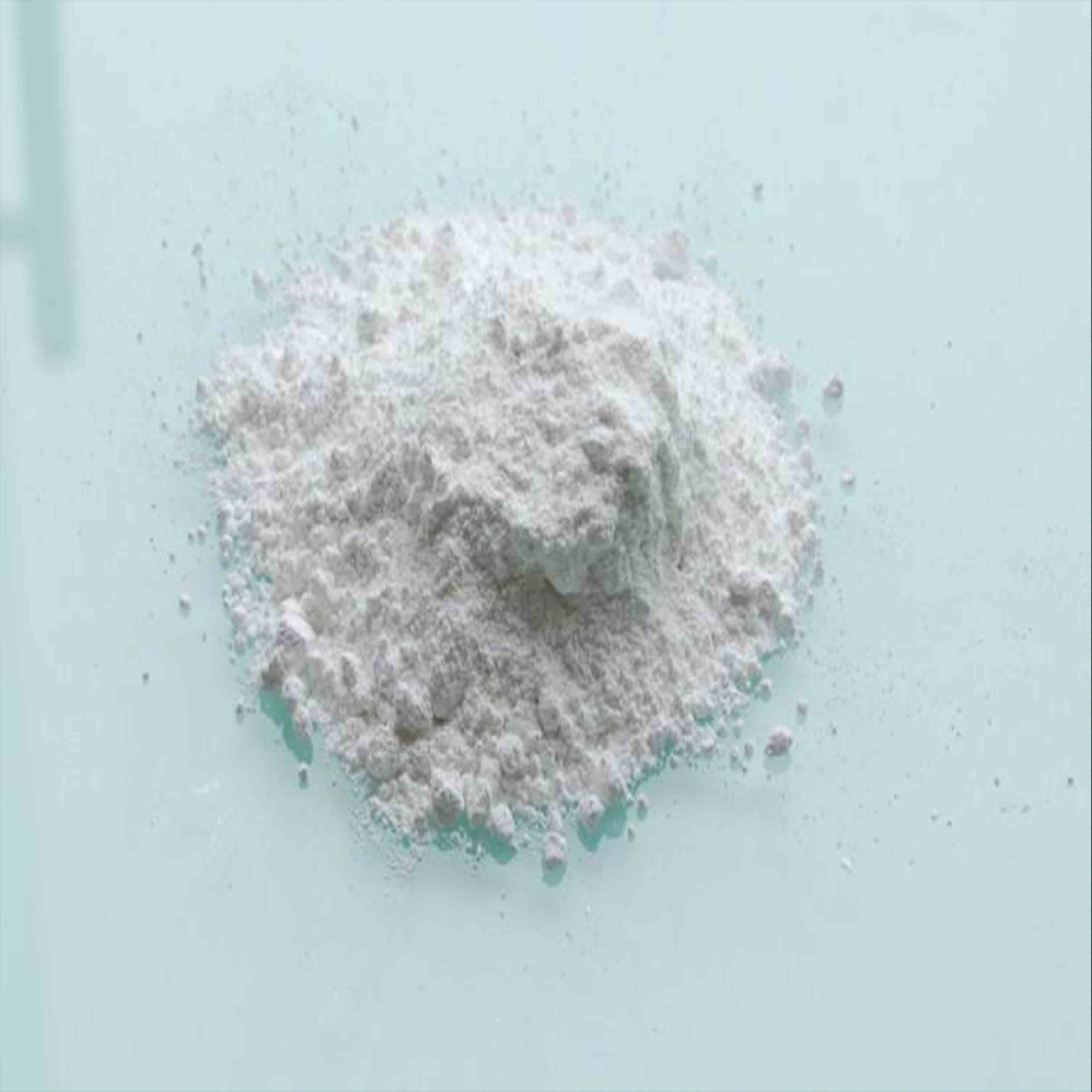

Lithopone is a white pigment historically used in paints, plastics, and other industries for its excellent opacity and durability. It is a mixture of zinc sulfide (ZnS) and barium sulfate (BaSO4), gaining attention for its cost-effectiveness and favorable performance characteristics. This article explores the composition of lithopone, its applications, and the importance of understanding its components ZnS and BaSO4.

Composition and Production of Lithopone

Lithopone typically consists of around 30% to 70% zinc sulfide and 30% to 70% barium sulfate, depending on the specific grade of the pigment. The production process involves the co-precipitation of these two components, which are both derived from natural minerals.

Zinc sulfide (ZnS) is produced by the reaction of zinc oxide with hydrogen sulfide or by heating zinc and sulfur together. It is valued for its brightness and lightfastness. Barium sulfate (BaSO4), on the other hand, is obtained through the reaction of barium chloride with sodium sulfate or by directly mining the mineral barite. The combination of these two components results in a stable and versatile white pigment that offers excellent hiding power.

Applications of Lithopone

Lithopone's primary application is in the paint industry, where it is used to improve the opacity and brightness of coatings. It provides excellent coverage compared to traditional white pigments and is particularly favored in applications where non-toxicity is a concern. Due to its high UV resistance, lithopone is commonly found in exterior paints and coatings, ensuring long-lasting results even when exposed to harsh weather conditions.

lithopone zns-baso4 quotes

Aside from paints, lithopone is also used in plastics, rubber, and paper industries. In plastics, it enhances the whiteness and finish of products, making it a preferred choice for manufacturers looking to achieve a premium look without compromising on performance. In rubber applications, it serves as both a filler and a pigment, contributing to the material's overall durability. Furthermore, in the paper industry, lithopone is utilized to improve the brightness and printability of various paper grades.

Advantages of Using Lithopone

One of the key advantages of lithopone is its environmental friendliness. Unlike some other white pigments, such as titanium dioxide, lithopone does not pose significant health risks, making it suitable for eco-conscious applications. Additionally, lithopone is often more cost-effective than titanium dioxide, providing substantial savings for industries that require large quantities of white pigment.

Another benefit of lithopone is its excellent stability. The compound remains unchanged under various conditions, ensuring consistent performance across different applications. This stability also means that lithopone can be used in various formulations without fear of degradation over time.

Challenges and Considerations

Despite its advantages, lithopone does have certain limitations. For instance, its transparency is not as high as that of titanium dioxide, which may affect its suitability in applications requiring a bright, opaque finish. Furthermore, the manufacturing process needs to be carefully controlled to ensure uniformity and quality, as variations in ZnS and BaSO4 ratios can impact the final pigment's performance.

In conclusion, lithopone, primarily composed of zinc sulfide and barium sulfate, is a versatile and environmentally friendly white pigment extensively used in various industries. Its unique properties, cost-effectiveness, and stability make it an attractive choice for manufacturers. However, understanding its composition and potential limitations is vital for optimizing its use in different applications. As industries continue to look for sustainable alternatives in pigment technology, lithopone stands out as a viable option in the ever-evolving landscape of modern manufacturing.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025