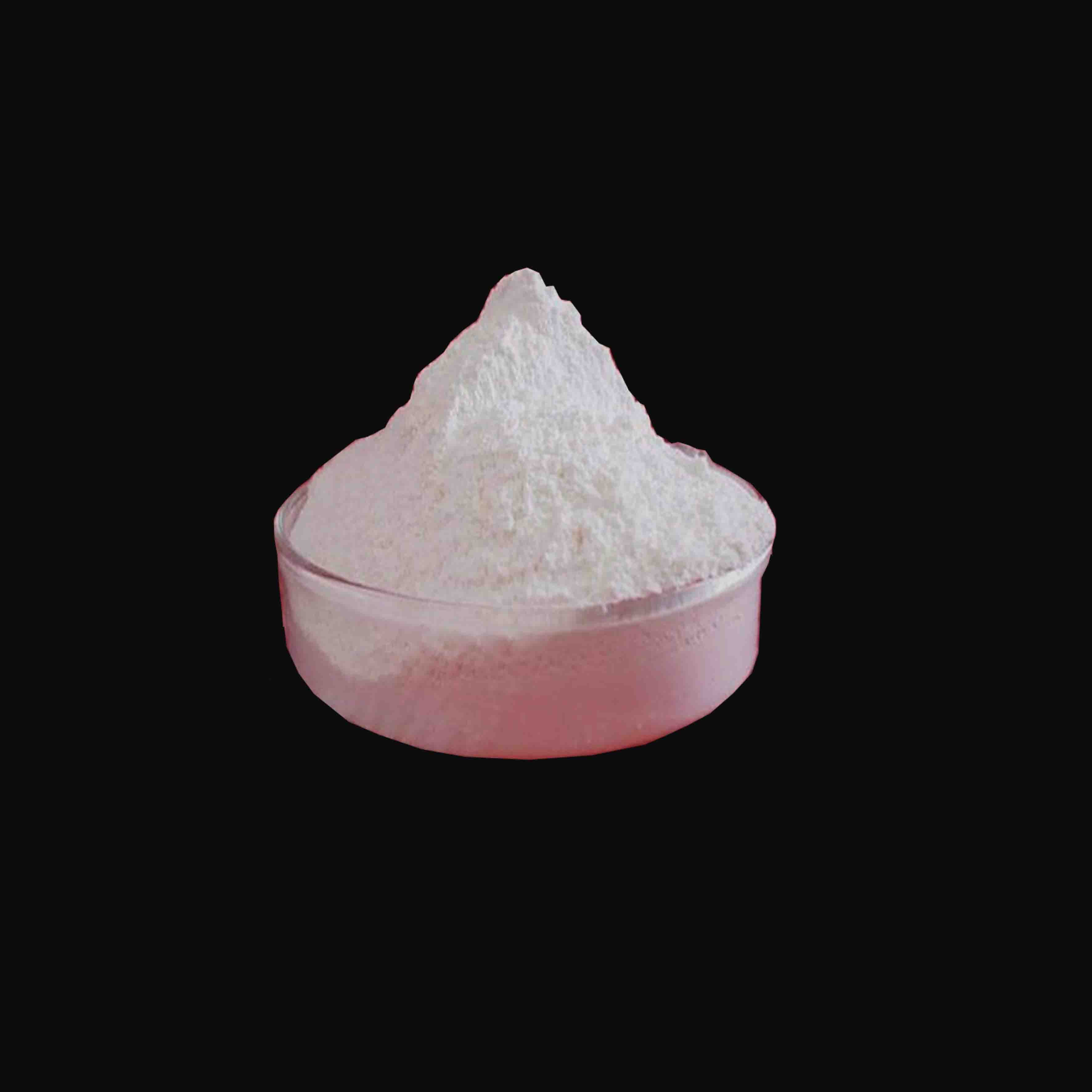

Industrial Titanium Dioxide with TIO2 >92% composition CAS 13463-67-7 Tio2

Jan . 09, 2025 10:45 Back to list

Industrial Titanium Dioxide with TIO2 >92% composition CAS 13463-67-7 Tio2

Selecting the right lithopone supplier can significantly impact the quality and efficiency of your production processes. A century-old compound, lithopone is a mixture of barium sulfate and zinc sulfide, often used as a pigment in paints, inks, leather, paper, and linoleum. Its ability to provide opacity and improve the brightness and durability of products makes it indispensable in industrial applications.

In terms of professionalism, consider a supplier's ability to offer customized solutions. This demonstrates expertise and a deep understanding of lithopone's applications, allowing for formulations that best match your product demands. Suppliers that offer technical support, whether through a knowledgeable customer service team or on-site technical consultants, can help resolve issues swiftly, reducing downtime and optimizing production processes. Additionally, logistics capabilities are critical. Reliable delivery schedules and efficient supply chains influence overall cost efficiency. A supplier with a global distribution network can offer flexibility, ensuring that disruptions in one part of the world do not impact your business. Inquire about their contingency plans to see how they manage supply chain disruptions. Lastly, pay attention to the relationship dynamics. Long-term partnerships with lithopone suppliers often yield the best results. A collaborative relationship built on communication, mutual understanding, and shared goals ensures that the supplier remains attuned to your evolving needs, adjusting product offerings as required to maintain market competitiveness. Ultimately, your selection of a lithopone supplier should rest on their comprehensive approach towards delivering excellence in product quality, operational expertise, reliability, and customer-centric services. Such suppliers not only provide materials but also contribute to the sustainable and profitable growth of your enterprise.

In terms of professionalism, consider a supplier's ability to offer customized solutions. This demonstrates expertise and a deep understanding of lithopone's applications, allowing for formulations that best match your product demands. Suppliers that offer technical support, whether through a knowledgeable customer service team or on-site technical consultants, can help resolve issues swiftly, reducing downtime and optimizing production processes. Additionally, logistics capabilities are critical. Reliable delivery schedules and efficient supply chains influence overall cost efficiency. A supplier with a global distribution network can offer flexibility, ensuring that disruptions in one part of the world do not impact your business. Inquire about their contingency plans to see how they manage supply chain disruptions. Lastly, pay attention to the relationship dynamics. Long-term partnerships with lithopone suppliers often yield the best results. A collaborative relationship built on communication, mutual understanding, and shared goals ensures that the supplier remains attuned to your evolving needs, adjusting product offerings as required to maintain market competitiveness. Ultimately, your selection of a lithopone supplier should rest on their comprehensive approach towards delivering excellence in product quality, operational expertise, reliability, and customer-centric services. Such suppliers not only provide materials but also contribute to the sustainable and profitable growth of your enterprise.

Latest news

-

What is Barium Sulfate Board? Uses, Benefits & Industry Insights

NewsNov.25,2025

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025