Nov . 09, 2024 22:36 Back to list

High-Quality 30% Lithopone Powder Manufacturer for Zinc Sulfide Applications

Lithopone Powder The Versatile Zinc Sulfide Compound

Lithopone powder, a pigment known for its bright white color and excellent coverage, is a compound that has garnered attention in various industrial applications. Formed by the mixture of zinc sulfide (ZnS) and barium sulfate (BaSO4), lithopone is predominantly used in paints, coatings, plastics, and paper. This article delves into its properties, manufacturing, applications, and market trends, particularly focusing on lithopone with 30% zinc sulfide.

Properties of Lithopone

Lithopone possesses several desirable properties that make it a preferred choice in many applications. Its high hiding power ensures that it effectively conceals surfaces, providing a smooth finish. The compound is also known for its superior stability and resistance to various environmental factors. It does not fall prey to yellowing, a common issue with other white pigments, particularly when exposed to heat or certain chemicals.

The specific formulation of lithopone powder with 30% zinc sulfide is particularly noteworthy. This concentration helps to enhance the pigment's ability to reflect light, imparting a brilliant whiteness that is highly sought after in paint formulations. The combination of zinc sulfide and barium sulfate offers a balance between brightness and opacity, making it versatile for a range of applications.

Manufacturing of Lithopone Powder

The production of lithopone involves a series of chemical reactions. The primary raw materials are zinc sulfate and barium sulfide, which react in the presence of sulfide ions to form the lithopone pigment. This process typically takes place in controlled conditions to ensure the uniformity and purity of the final product.

Manufacturers often emphasize quality control throughout the production cycle, as impurities can significantly affect the performance of the pigment. Advanced techniques such as micronization are employed to achieve the desired particle size, improving the dispersion of the powder in various media.

lithopone powder lithopone zns 30% manufacturer

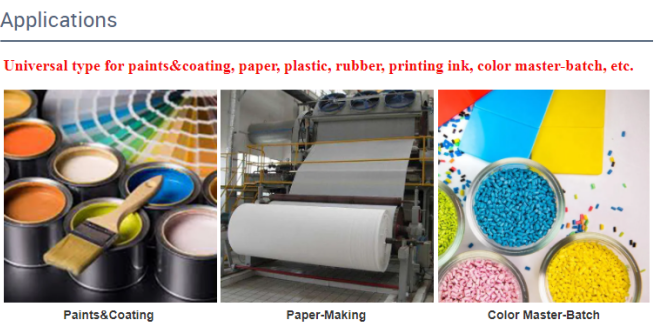

Applications of Lithopone

Lithopone powder is most widely used in the paint and coatings industry. Its superior opacity allows for thinner coatings, which can lead to cost reductions and environmental benefits by reducing the amount of raw materials used. Additionally, its brightness enhances the aesthetic appeal of painted surfaces, making it a favorite among manufacturers.

The plastic industry also benefits from lithopone, where it is used as a filler and pigment in products ranging from toys to automotive parts. In paper production, lithopone acts as a whitening agent, improving the brightness and quality of the final product.

Furthermore, lithopone is gaining traction in the cosmetics industry, particularly in formulations requiring high opacity and whiteness. It is crucial to note, however, that safety regulations must be followed, given the stringent guidelines related to cosmetic ingredients.

Market Trends and Future Prospects

The global market for lithopone powder, particularly the variant containing 30% zinc sulfide, is witnessing steady growth. Factors driving this demand include the increasing need for high-quality pigments across industries, particularly in emerging economies where infrastructure development is on the rise.

As sustainability becomes a priority, manufacturers are exploring eco-friendly alternatives and production processes. The drive toward reducing the environmental impact of chemical manufacturing will likely shape the future of lithopone powder production.

In conclusion, lithopone powder with 30% zinc sulfide is a remarkable compound that plays a crucial role in various industries due to its bright white color, excellent hiding power, and stability. As manufacturing practices evolve and the demand for high-quality, sustainable products increases, lithopone is poised to maintain its importance in the pigment market. Its versatility and performance make it a cornerstone in the formulation of paints, plastics, and beyond.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025