Sep . 23, 2024 18:26 Back to list

Lithopone Safety Data Sheets and Pricing Information from Manufacturers

Understanding Lithopone MSDS, Pricing, and Manufacturers

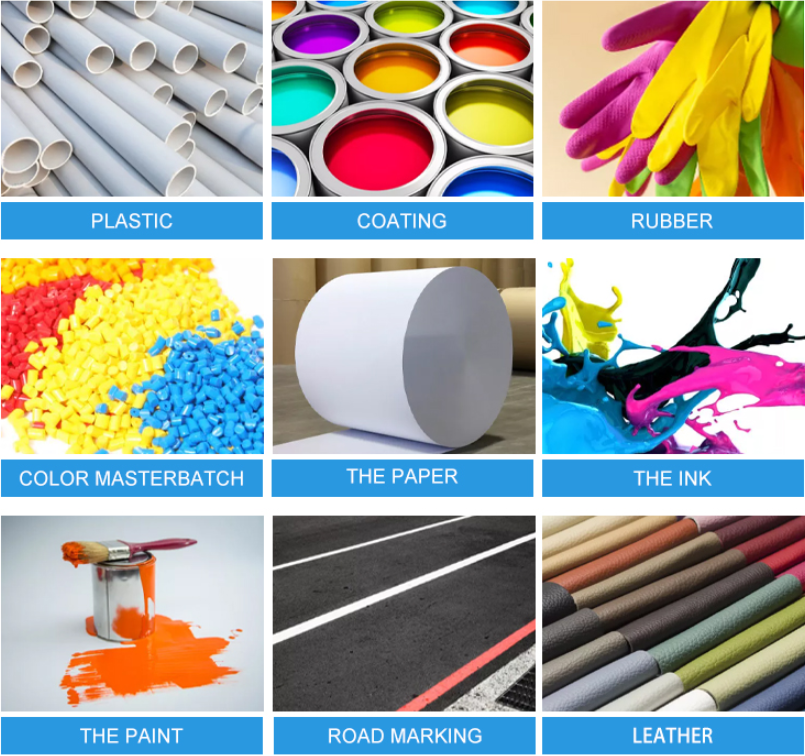

Lithopone is a white pigment composed of zinc sulfide and barium sulfate, used extensively in coatings, plastics, and various other applications. Its unique properties make it an important player in many industries, particularly in the production of paints, inks, and plastics. As with any industrial material, it’s vital for manufacturers and users to understand its safety, pricing, and sourcing. This article will explore lithopone, focusing on its Material Safety Data Sheet (MSDS), price considerations, and manufacturers in the market.

Material Safety Data Sheet (MSDS)

The MSDS for lithopone provides essential information regarding the safety and handling of this pigment. It outlines the physical and chemical properties, health hazards, safe handling practices, and emergency response measures. Key components typically covered in the MSDS include

1. Chemical Identification Lithopone is generally identified by its chemical composition, primarily zinc sulfide (ZnS) and barium sulfate (BaSO4).

2. Hazard Identification While lithopone is considered non-toxic under normal handling conditions, inhalation of dust or prolonged skin contact can cause irritation. Therefore, it is crucial to implement appropriate safety measures, such as using personal protective equipment (PPE) like gloves and masks.

3. First-Aid Measures In the event of exposure, the MSDS provides guidelines for first aid. For instance, if dust is inhaled, moving to fresh air and seeking medical attention is recommended.

4. Handling and Storage To ensure safe use of lithopone, it’s important to store the material in a cool, dry place and to handle it with care to avoid creating dust.

Understanding the MSDS is essential for manufacturers and end-users to ensure safety and compliance with regulations.

Pricing Considerations

The price of lithopone can vary based on multiple factors, including purity, production methods, and market demand. Typically, lithopone is priced competitively compared to other white pigments like titanium dioxide, making it an attractive option for manufacturers looking to reduce costs.

lithopone msds pricelist manufacturers

1. Market Fluctuations The price of lithopone may fluctuate based on supply chain dynamics, including raw material costs and production capacities. Natural disasters, geopolitical tensions, and changes in regulatory frameworks can all impact availability and pricing.

2. Quality and Purity Higher purity levels usually command higher prices. Manufacturers often specify purity levels based on their intended applications, and it is essential to consider the performance characteristics desired for each use case.

3. Volume Purchases Bulk buying can result in significant savings. Many manufacturers offer discounts for larger orders, which can be beneficial for companies with extensive production needs.

Major Manufacturers

The market for lithopone is served by several key manufacturers. Understanding who these manufacturers are and their various offerings can be critical for procurement and relationship management.

1. International Players Major global firms specialize in the production of lithopone and related pigments. Companies such as Huntsman, Kronos, and Tronox are recognized for their quality and reliability in the pigment market.

2. Regional Suppliers There are plenty of regional suppliers who offer competitive pricing and localized service. These suppliers may cater to specific markets or applications, providing a more tailored approach to customer needs.

3. Customization Some manufacturers offer customized lithopone formulations optimized for specific applications, allowing users to achieve the desired balance between performance and cost.

Conclusion

In conclusion, lithopone remains a vital component in a variety of industrial applications due to its favorable characteristics and cost-effectiveness. For manufacturers, understanding the MSDS is crucial for maintaining safety standards, while keeping abreast of pricing trends and reliable manufacturers can help optimize procurement strategies. As industries continue to evolve and new applications for lithopone emerge, staying informed about these factors will be essential for success in the market.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025