Dec . 11, 2024 04:23 Back to list

Leading Lithopone Producers in China for High-Quality Pigments and Coatings

Lithopone Manufacturers in China An Overview

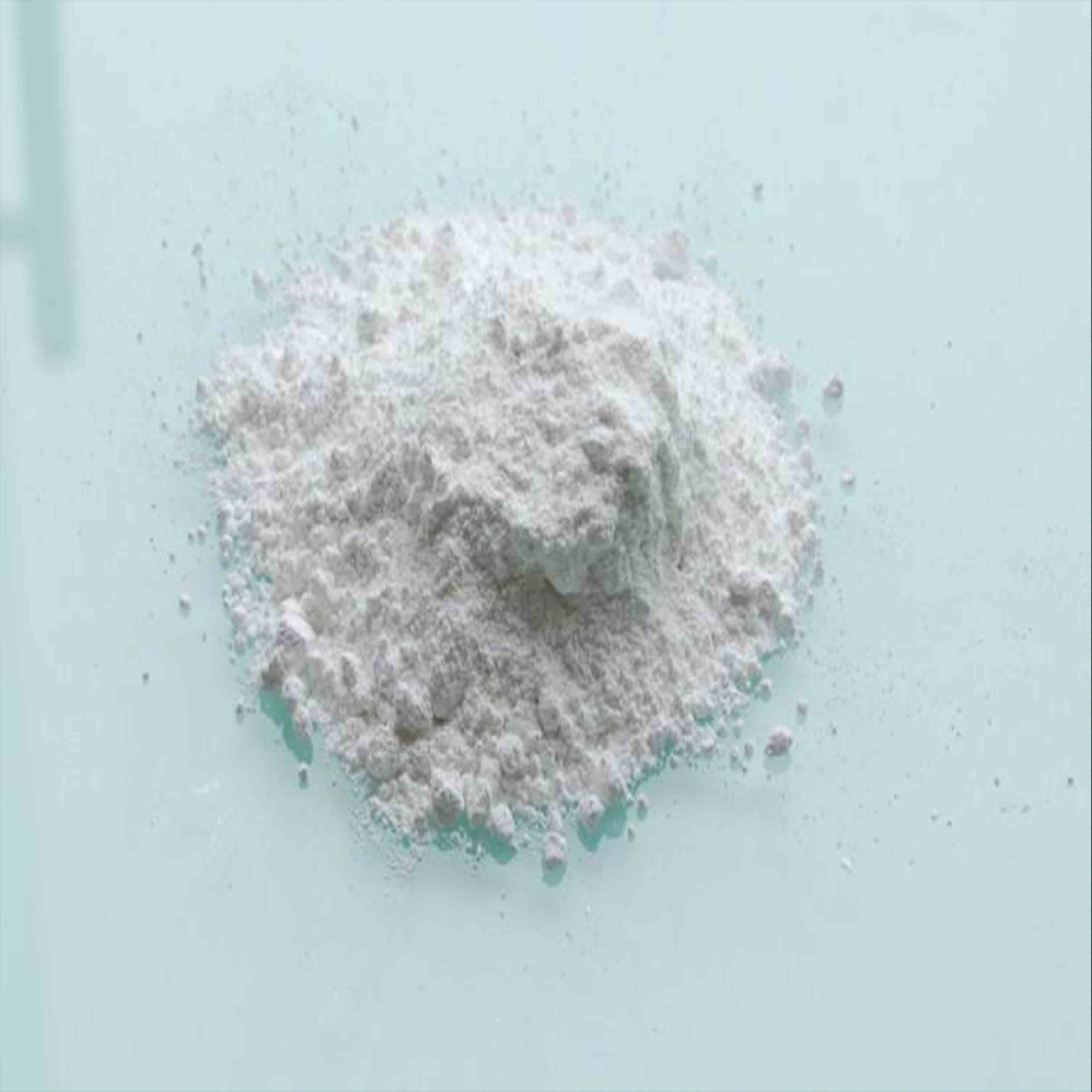

Lithopone, a white pigment primarily composed of zinc sulfide and barium sulfate, has gained significant attention in various industries due to its excellent properties, such as high opacity, good weather resistance, and non-toxicity. In recent years, China has emerged as one of the leading manufacturers of lithopone, catering to both domestic and international markets. This article explores the landscape of lithopone manufacturing in China, highlighting key manufacturers, production processes, and market trends.

Understanding Lithopone

Before delving into the manufacturing aspect, it is crucial to understand what lithopone is and why it is important. Developed in the early 19th century, lithopone was initially used as a white pigment in paints, coatings, and plastics. Its appeal lies in its capability to replace toxic pigments such as lead white and titanium dioxide. Lithopone is known for its brightness, odorlessness, and resistance to fading and yellowing, making it suitable for a wide range of applications, including

- Paints and coatings - Plastics - Rubber - Ink - Cosmetics

Given these diverse applications, the demand for lithopone continues to grow, particularly in emerging markets across Asia, Africa, and Latin America.

Major Lithopone Manufacturers in China

China is home to several prominent lithopone manufacturers, many of which have established themselves as key players in the global market. Some notable companies include

1. Sichuan University of Science and Engineering Known for its innovative research in materials science, this institution has also ventured into the production of high-quality lithopone.

2. Guangdong Liyang Chemical Co., Ltd. This manufacturer has specialized in the production of various chemical products, including lithopone. Its commitment to quality and sustainability has made it a preferred supplier for numerous industries.

3. Yanato Technology Co., Ltd. With a production capacity of several tons per day, Yanato Technology is recognized for its competitive pricing and premium-grade lithopone pigments that meet international standards.

4. Shijiazhuang Shuanghua Chemicals Co., Ltd. This company is renowned for producing high-grade lithopone under strict quality control measures. It exports a significant portion of its output to countries including the United States, Germany, and India.

lithopone manufacturer in china

These manufacturers leverage modern production techniques, quality control measures, and research and development facilities to produce superior lithopone products that cater to varying international standards.

Production Processes

The production of lithopone involves a series of chemical reactions and processes that typically includes the following steps

1. Raw Material Sourcing The primary raw materials for lithopone production are zinc sulfide (ZnS) and barium sulfate (BaSO4). Sourcing high-purity raw materials is essential for achieving high-quality end products.

2. Preparation The raw materials undergo grinding and mixing to achieve a uniform distribution of components. It usually involves milling and classifier techniques to control particle size.

3. Chemical Reactions The mixed materials are subjected to chemical treatments, typically involving precipitation and calcination processes. This step is crucial in forming lithopone pigments.

4. Washing and Drying After the reaction, the resultant compound needs thorough washing to remove impurities. The washed product is then dried to eliminate moisture, ensuring a stable pigment.

5. Quality Control Rigorous testing is conducted to ensure that the lithopone meets industry standards for brightness, opacity, fineness, and chemical composition.

Market Trends and Future Outlook

The lithopone market in China is poised for growth, driven by increasing demand from industries that prioritize eco-friendly and non-toxic materials. The push toward sustainable practices is likely to enhance the market for lithopone, given its non-toxic nature compared to traditional pigments.

Moreover, advancements in production techniques can further optimize the manufacturing processes, leading to cost reductions and improved product quality. As more manufacturers adopt automation and sophisticated technologies, competitive pricing will benefit wider applications of lithopone.

In conclusion, China’s lithopone manufacturers not only play a critical role in meeting domestic needs but also significantly contribute to the global market. With a growing emphasis on sustainability and eco-friendly practices, the future of lithopone manufacturing in China looks promising, positioning the country as a central hub in the pigment industry.

-

Best Baso4 Price Wholesale & Manufacturer Deals in China

NewsApr.29,2025

-

Rutile Titanium Dioxide R698 Supplier Coating & Paint Solutions

NewsApr.29,2025

-

Premium Titanium Dioxide Ultra White Paint High-Coverage & Durable

NewsApr.29,2025

-

China Titanium & TiO2 Powder Factory Reliable Rutile & Lithopone Supplier

NewsApr.28,2025

-

Titanium Dioxide Types High-Purity Grades from Trusted Factories & Suppliers

NewsApr.28,2025

-

High-Quality Titanium Dioxide White Pigments Wholesale Supplier

NewsApr.28,2025