lithopone manufacturer

Jan . 09, 2025 11:29 Back to list

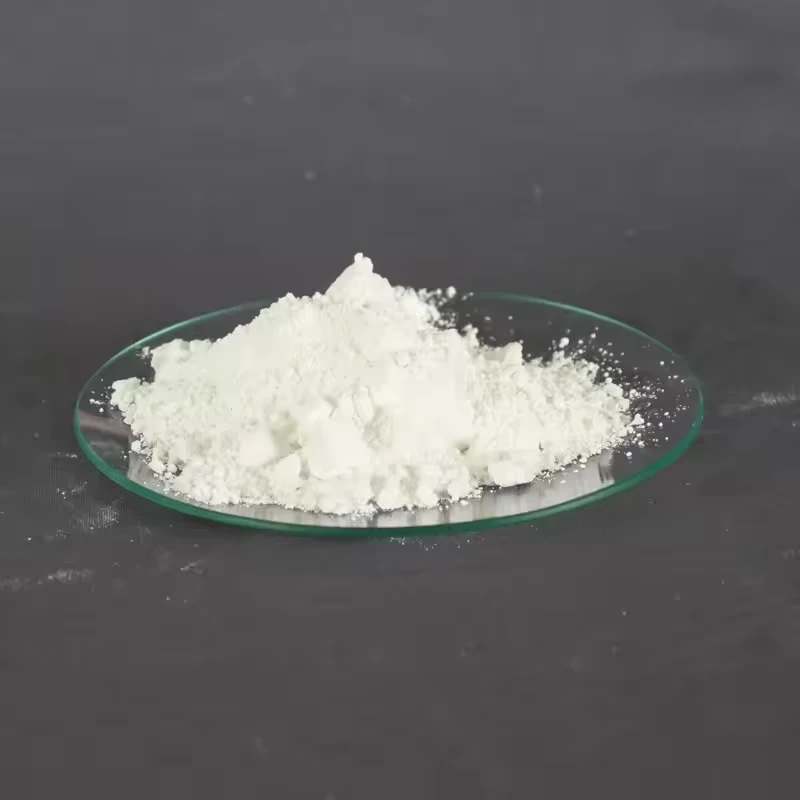

lithopone manufacturer

Locating the right lithopone manufacturer is paramount for industries relying on high-quality pigment solutions. Lithopone, a compound consisting of barium sulfate and zinc sulfide, is a pivotal material used across diverse applications including paints, coatings, plastics, and even cosmetics due to its unique properties like high brightness and excellent coverage. When selecting a lithopone manufacturer, it's crucial to consider aspects such as production capacity, technological expertise, and quality assurance practices, all of which underscore a company's authority and reliability in the field.

Investing in quality control is equally vital. Reliable manufacturers implement stringent testing protocols to ensure the consistency and purity of the lithopone produced. This includes state-of-the-art laboratory facilities and a team of seasoned chemists and materials scientists who diligently oversee the quality assurance process. Regular audits and continuous improvement initiatives convey the manufacturer’s commitment to maintaining high standards, thereby solidifying their reputation as industry leaders. The experience of working with a seasoned lithopone manufacturer can significantly impact the outcome of the finished product. Such companies often provide extensive customer support, including technical assistance and detailed product information, empowering manufacturers to select the appropriate pigment concentration tailored to their specific applications. Furthermore, experienced manufacturers typically have a global presence, offering logistical advantages to clients across various geographies, which facilitates timely delivery and reliable supply chain management. In conclusion, selecting the right lithopone manufacturer involves an assessment of their expertise, commitment to quality, and environmental responsibility. By prioritizing these aspects, businesses can forge partnerships with manufacturers capable of providing innovative, reliable, and sustainable pigment solutions, thereby ensuring product excellence and market competitiveness.

Investing in quality control is equally vital. Reliable manufacturers implement stringent testing protocols to ensure the consistency and purity of the lithopone produced. This includes state-of-the-art laboratory facilities and a team of seasoned chemists and materials scientists who diligently oversee the quality assurance process. Regular audits and continuous improvement initiatives convey the manufacturer’s commitment to maintaining high standards, thereby solidifying their reputation as industry leaders. The experience of working with a seasoned lithopone manufacturer can significantly impact the outcome of the finished product. Such companies often provide extensive customer support, including technical assistance and detailed product information, empowering manufacturers to select the appropriate pigment concentration tailored to their specific applications. Furthermore, experienced manufacturers typically have a global presence, offering logistical advantages to clients across various geographies, which facilitates timely delivery and reliable supply chain management. In conclusion, selecting the right lithopone manufacturer involves an assessment of their expertise, commitment to quality, and environmental responsibility. By prioritizing these aspects, businesses can forge partnerships with manufacturers capable of providing innovative, reliable, and sustainable pigment solutions, thereby ensuring product excellence and market competitiveness.

Next:

Latest news

-

What is Barium Sulfate Board? Uses, Benefits & Industry Insights

NewsNov.25,2025

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025