Nov . 20, 2024 01:24 Back to list

lithopone is factory

Lithopone An Insight into Its Factory Production

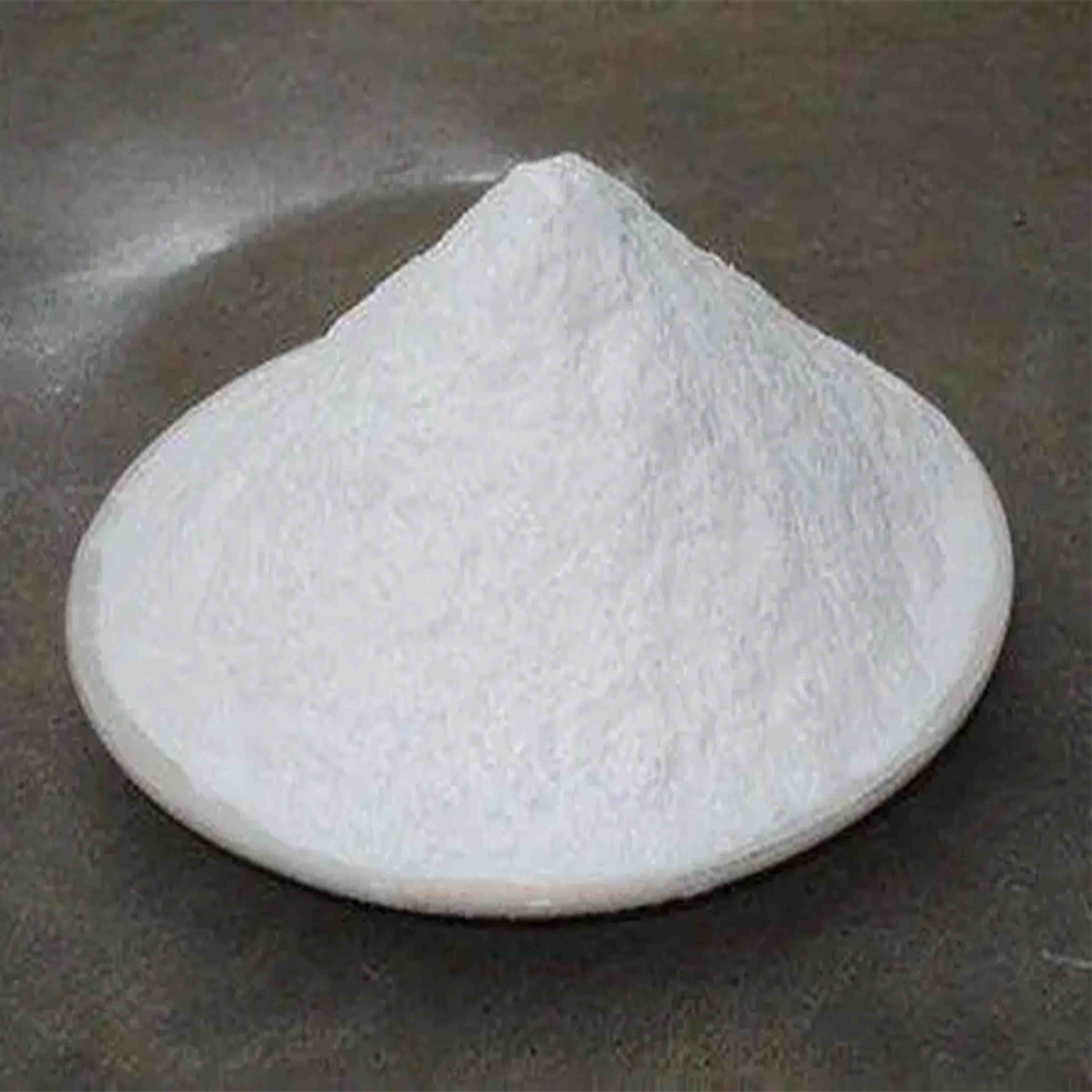

Lithopone is a fascinating chemical compound, primarily used as a white pigment in various applications including paints, coatings, plastics, and paper. It is a mixture of barium sulfate (BaSO₄) and zinc sulfide (ZnS), and its unique properties, such as high opacity, stability, and non-toxicity, make it a popular choice in the pigment industry. Understanding the processes undertaken in a factory setting to produce lithopone can provide valuable insights into its commercial importance and application.

The production of lithopone typically involves several key steps. The initial phase begins with the preparation of raw materials. The manual handling and precise measurement of barium sulfate and zinc sulfide are crucial to ensure a consistent quality of the final product. Factories usually source high-purity raw materials to avoid any unwanted impurities that could affect the performance of lithopone.

Lithopone An Insight into Its Factory Production

After blending, the mixture is subjected to a calcination process, which involves heating the combined materials in a furnace at high temperatures (usually around 800 to 1000 degrees Celsius). Calcination serves multiple purposes it aids in the proper synthesis of lithopone and helps eliminate any residual moisture from the blend. The high temperatures facilitate the chemical reaction between the barium sulfate and zinc sulfide, leading to the formation of lithopone.

lithopone is factory

Following calcination, the cooled product is then subjected to a fine-grinding process. This step is crucial as it determines the particle size of the final pigment. A finer particle size enhances the opacity and covering power of lithopone, which is essential for its effectiveness as a pigment. Factories utilize various grinding techniques, including ball milling, to achieve the desired consistency.

Upon achieving the correct particle size, the lithopone is subject to a quality control phase. This step involves rigorous testing of the pigment for various parameters, such as color strength, opacity, and particle size distribution. Quality control is vital in ensuring that the lithopone meets industry standards and client specifications. This is often achieved through both visual inspections and sophisticated analytical techniques.

Once the lithopone has passed quality control, it is packaged for distribution. Factories typically package the pigment in moisture-resistant materials to preserve its quality during transportation and storage. The packaging process is automated in most modern factories, ensuring efficiency and consistency in output.

In conclusion, the factory production of lithopone is a multi-faceted process that combines the careful selection of raw materials, precision in mixing and calcination, grinding, and stringent quality control measures. As a widely used white pigment in many industries, understanding the manufacturing processes behind lithopone not only highlights its significance but also showcases the complexity and attention to detail involved in its production. The robust manufacturing practices associated with lithopone ensure its continued relevance in various applications, contributing to its status as a valuable compound in the world of pigments.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025