Nov . 12, 2024 16:43 Back to list

lithopone in pigment quotes factory

The Importance of Lithopone in the Pigment Industry

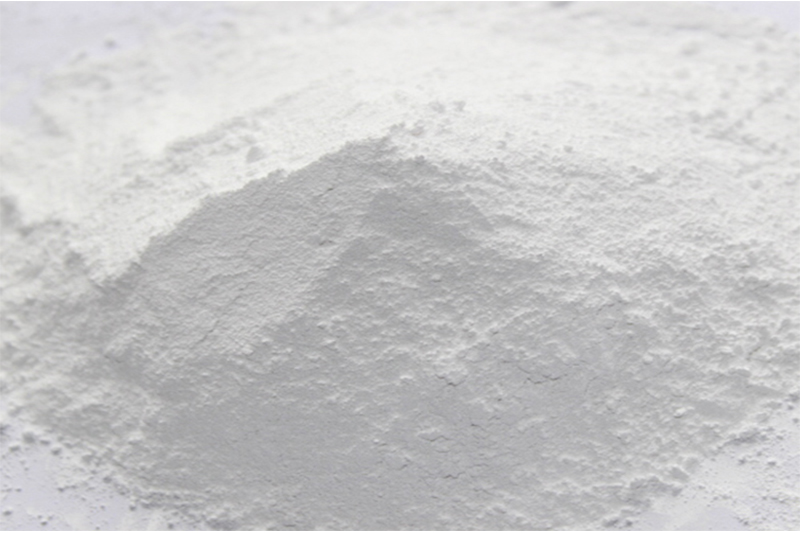

Lithopone is a white pigment composed primarily of zinc sulfide and barium sulfate. It has been widely used in various applications, particularly in the paint and coatings industry, due to its excellent opacity, brightness, and resistance to weathering. This article explores the significance of lithopone in the pigment market, its properties, advantages, and the future of its production and usage in factories.

Properties of Lithopone

Lithopone combines the characteristics of both zinc sulfide and barium sulfate, resulting in a unique pigment that is highly valued in commercial applications. Its main properties include

1. Opacity Lithopone offers superior hiding power, allowing manufacturers to produce paint with fewer layers while maintaining an aesthetic finish. 2. Whiteness The brightness and high refractive index of lithopone make it an ideal choice for achieving a vivid white color in paints and coatings. 3. Chemical Stability It is resistant to chemicals and provides long-lasting results when used in various environments. 4. Non-Toxic Nature Unlike some other white pigments, lithopone is generally regarded as non-toxic, making it a safer option for consumers and manufacturers alike.

Applications of Lithopone

Lithopone is primarily used in a variety of industries including

- Paint and Coatings It is extensively employed in the formulation of exterior and interior paints where durability and weather resistance are critical. - Plastics As a pigment, lithopone is added to plastics to enhance brightness and fade resistance, making it suitable for various consumer goods. - Inks Lithopone is also utilized in ink production, particularly in printing applications that demand high-quality finishes.

lithopone in pigment quotes factory

Advantages Over Other Pigments

Lithopone holds several advantages compared to other white pigments, such as titanium dioxide. Although titanium dioxide is recognized for its excellent covering properties, lithopone is often more cost-effective, providing manufacturers with a balance between quality and price. Additionally, lithopone's performance in a wide range of temperatures and its ability to retain brightness over time make it a preferred choice in outdoor applications.

The Future of Lithopone Production

With increasing environmental regulations and consumer demand for sustainable products, the production methods for lithopone are evolving. Factories are investing in research and development to produce lithopone in an environmentally friendly manner. Innovative practices now focus on minimizing waste and utilizing renewable resources in the manufacturing process.

Market trends indicate a growing preference for non-toxic and eco-friendly pigments, aligning with the production of lithopone. Manufacturers are exploring ways to reduce the carbon footprint associated with its production, which will likely enhance its popularity in future applications. Moreover, as awareness grows around the effects of synthetic pigments on health and the environment, lithopone's non-toxic properties position it well for continued usage in consumer goods.

Conclusion

Lithopone plays a crucial role in the pigment industry, appreciated for its outstanding qualities and versatility. As more factories recognize the importance of sustainable practices and consumer welfare, the future of lithopone looks bright. Its continued innovation in production processes will not only benefit manufacturers but also contribute positively to environmental efforts. By embracing lithopone, the industry can meet the growing demand for quality pigments that align with health and sustainability standards, ensuring its relevance for years to come.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025