Oct . 31, 2024 22:16 Back to list

Benefits of Lithopone in Plastic Production for Manufacturers and Formulators

Lithopone A Versatile Solution for Plastic Manufacturers

In the realm of plastic manufacturing, finding the right additives is crucial for enhancing the quality and performance of the final products. One such additive that has gained considerable attention is lithopone, a white pigment that offers a myriad of benefits for plastic manufacturers. Composed primarily of zinc sulfide and barium sulfate, lithopone not only serves as a coloring agent but also improves the overall properties of plastic materials.

Properties of Lithopone

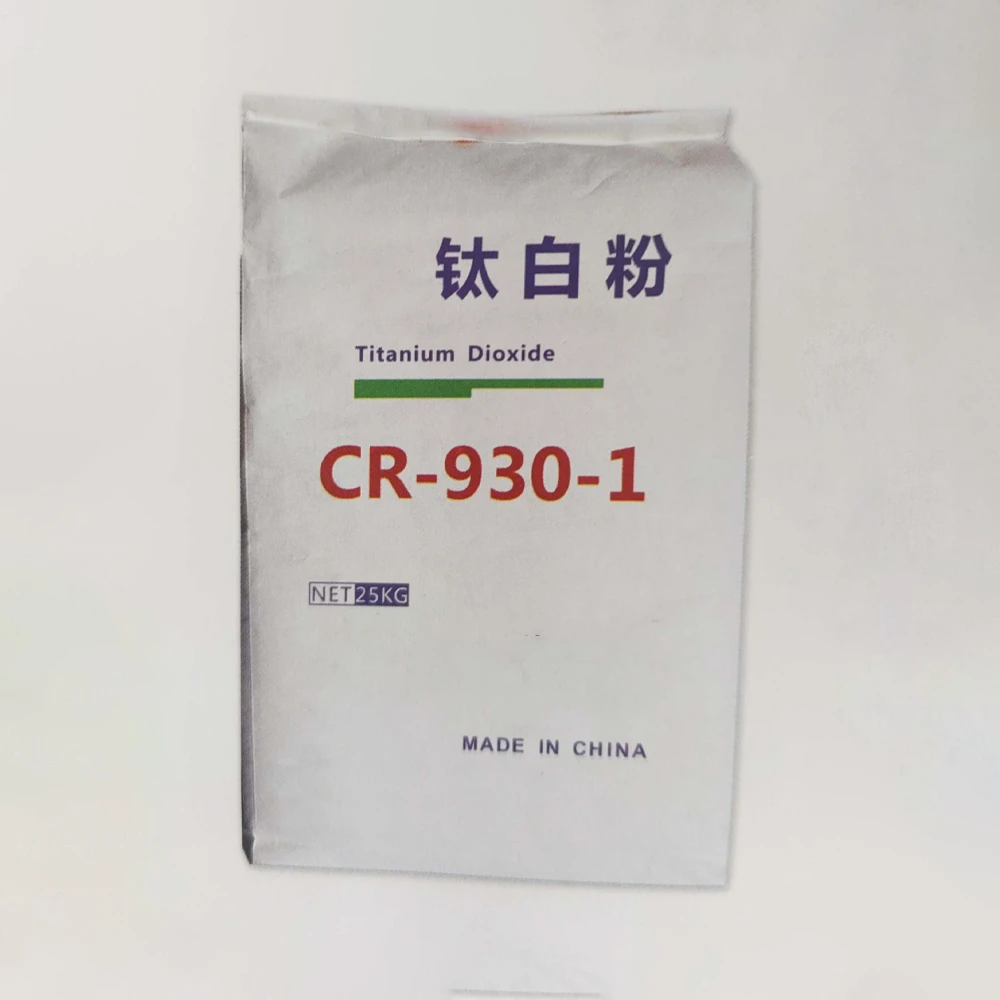

Lithopone is distinguished by its excellent opacity and brightness, making it an ideal choice for achieving a high level of whiteness in plastic products. Unlike traditional titanium dioxide, which is often used for similar purposes, lithopone has a lower refractive index, resulting in reduced yellowing over time. This characteristic is especially beneficial for outdoor applications where plastics are exposed to UV light and harsh weather conditions. Furthermore, lithopone exhibits good thermal stability, making it suitable for processing at higher temperatures typically encountered in the plastic manufacturing process.

Advantages in Plastic Applications

The incorporation of lithopone in plastics can significantly enhance their mechanical properties. For instance, it can improve tensile strength and impact resistance, which are critical for products requiring durability. Additionally, lithopone is known for its chemical inertness; this property enables it to maintain its integrity, thereby not compromising the overall stability of the plastic matrix.

lithopone for plastic manufacturers

Moreover, lithopone can contribute to the reduction of production costs. As a lower-cost alternative to titanium dioxide, it allows manufacturers to maintain product quality while optimizing their budgets. By using lithopone, manufacturers can achieve desired whiteness and opacity without excessive reliance on more expensive pigments, creating a more cost-effective production process.

Environmental Considerations

As the world becomes increasingly conscious of environmental impact, the importance of using eco-friendly materials in plastic manufacturing cannot be overstated. Lithopone is regarded as a relatively safe pigment, and its use can contribute to the development of greener products. It helps plastic manufacturers comply with regulatory standards that aim to minimize the use of harmful substances. Additionally, lithopone's natural mineral characteristics align with the growing trend toward sustainable and biodegradable materials.

Conclusion

In conclusion, lithopone emerges as a highly beneficial additive for plastic manufacturers seeking to improve product quality while managing costs. Its favorable properties—such as excellent opacity, durability, and environmental safety—make it a versatile choice for a variety of plastic applications. As the industry continues to evolve with the demand for higher performance and sustainability, lithopone stands out as a reliable solution that meets both the technical and environmental needs of modern plastic manufacturing. With its integration, manufacturers can not only enhance their products but also position themselves favorably in a competitive market that values both quality and sustainability.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025