Oct . 19, 2024 22:39 Back to list

lithopone factories

Understanding Lithopone Factories A Comprehensive Overview

Lithopone, a pigment composed primarily of zinc sulfide and barium sulfate, has garnered attention in various industries due to its excellent properties as a white pigment. Often utilized in paints, coatings, plastics, and other applications, the production of lithopone originates from specialized factories that are adept in handling the chemical processes involved. This article delves into the intricacies of lithopone factories, exploring their operations, production methods, and the significance of lithopone in industrial applications.

The Production Process of Lithopone

The manufacturing of lithopone involves a careful chemical reaction between zinc sulfate and barium sulfide. The primary components, zinc and barium, are sourced from their respective ores, sphalerite and witherite. These ores undergo a series of treatments, including roasting and leaching, to extract the desired metal compounds.

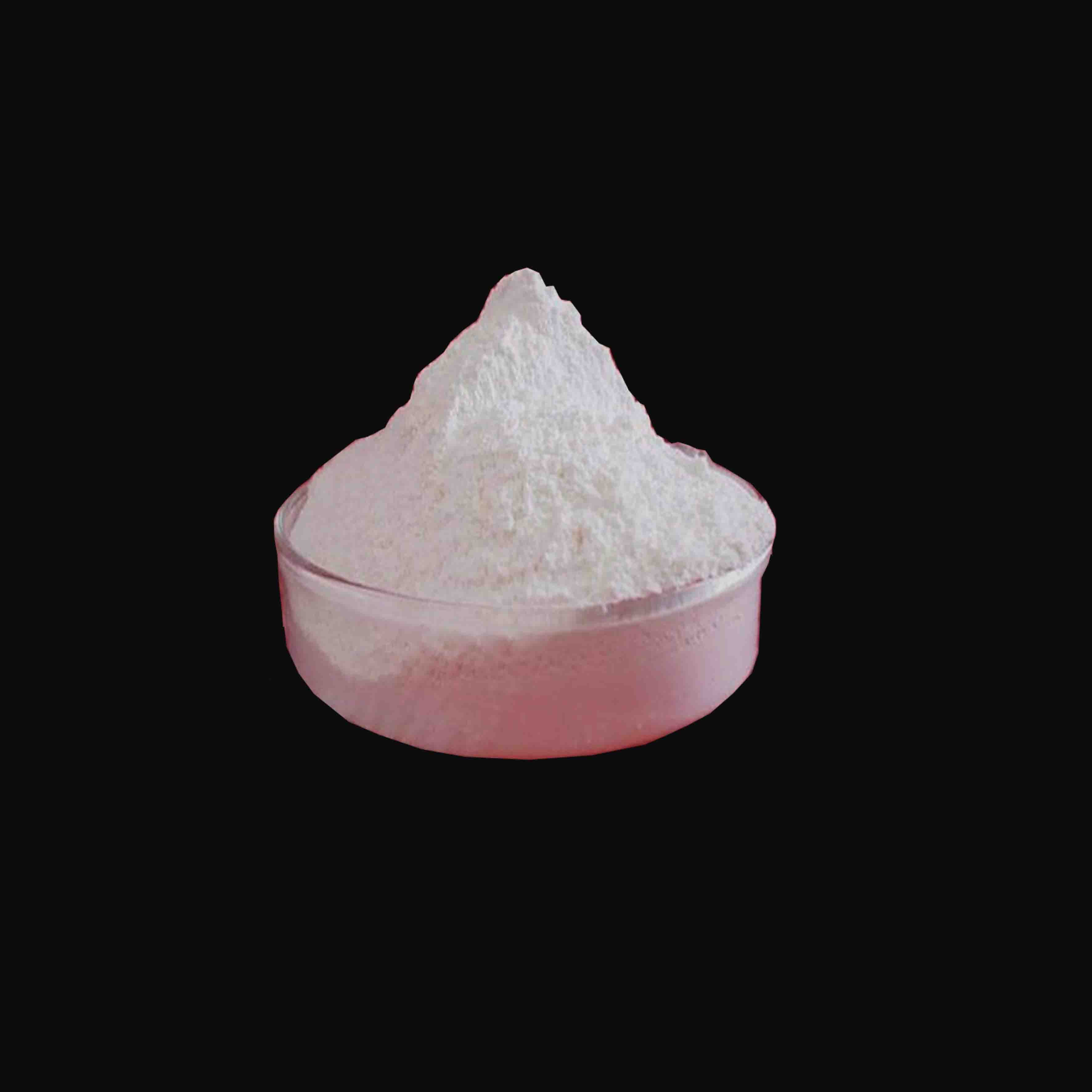

Once the raw materials are prepared, the key step in lithopone production occurs. The zinc sulfate solution is mixed with barium sulfide, leading to the precipitation of lithopone. This precipitation process is crucial as it significantly influences the quality of the final product, dictating factors like particle size and dispersibility. The resultant precipitate is then filtered, washed, and dried, creating a fine white powder that is the final lithopone product.

Key Technologies in Lithopone Factories

Modern lithopone factories employ advanced technologies to enhance productivity and ensure the consistency of their products. Techniques such as continuous flow reactors and automated filtration systems are prevalent and contribute to a more efficient manufacturing process. Continuous flow reactors allow for the constant mixing of reactants, optimizing the reaction time and improving yield rates.

Moreover, the integration of quality control systems is critical in lithopone production. These systems monitor parameters such as temperature and pH levels throughout the production process, ensuring that the final product meets the required specifications. This level of precision is essential, particularly in industries where the quality of pigments directly affects the performance of the end products.

Environmental Considerations

lithopone factories

Given the industrial nature of lithopone production, environmental sustainability has become a crucial focus for many factories. The use of closed-loop systems enables the recycling of water and other chemicals, minimizing waste and reducing the pollution typically associated with chemical manufacturing. Additionally, many factories are adopting eco-friendly practices, such as utilizing renewable energy sources and employing green chemistry principles to reduce their environmental footprint.

Applications of Lithopone

Lithopone is versatile and finds applications across numerous sectors. Its most common use is as a white pigment in paints, where it provides excellent opacity and brightness. The construction industry also benefits from lithopone, using it in the formulation of materials like cement and plaster where durability and aesthetic appeal are essential.

Furthermore, lithopone is significant in the plastics and rubber industries and acts as a filler in various composites. Its heat-resistance properties make it suitable for manufacturing electrical insulators as well. The pharmaceutical and cosmetic industries also harness the benefits of lithopone, employing it in products where color and stability are essential.

The Global Market for Lithopone

Factory production of lithopone has become a global enterprise, with key manufacturing hubs located in countries like China, India, and the United States. The increasing demand for white pigments in numerous consumer goods indicates a growing market for lithopone. Additionally, as industries pursue more sustainable practices, lithopone's eco-friendly production methods position it favorably among competitors.

Conclusion

Lithopone factories play a crucial role in the manufacturing of one of the most widely used white pigments in the world. The intricate processes involved, combined with a commitment to quality and environmental sustainability, highlight the importance of these facilities in meeting not only current but also future demands in various industries. As technology advances and sustainable practices continue to evolve, lithopone’s presence in the global market is likely to become even more pronounced, further underscoring its significance in modern manufacturing.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025