Dec . 10, 2024 02:07 Back to list

Lithopone B311 Production and Manufacturing Insights from Leading Factories

Lithopone B311 A Comprehensive Overview of its Factories and Applications

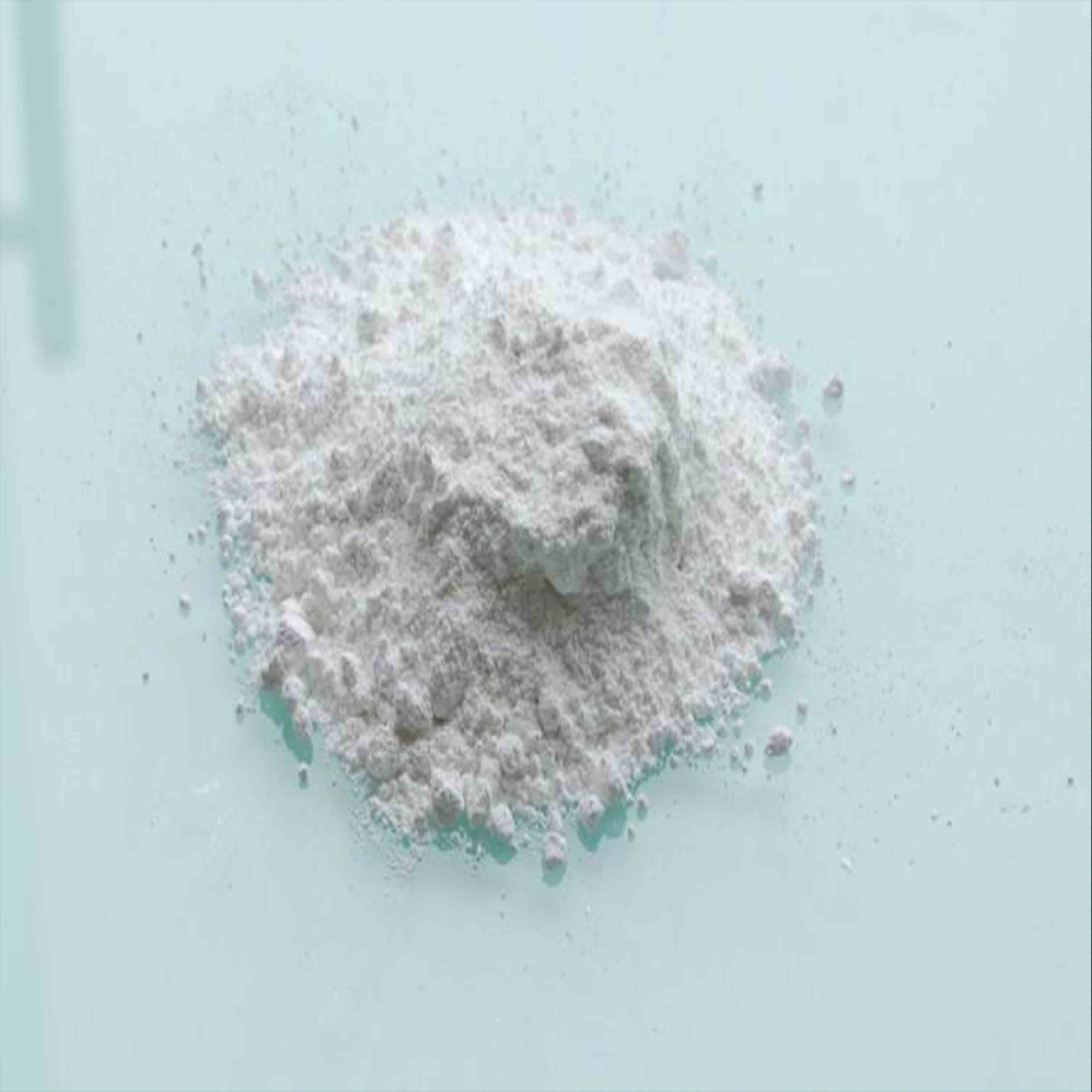

Lithopone, a white pigment made from a combination of zinc sulfide and barium sulfate, has been used extensively in the paint, plastics, and paper industries due to its excellent opacity, brightness, and durability. Among the different grades of lithopone, Lithopone B311 stands out as a highly versatile product that meets various industrial demands. This article delves into the factories producing Lithopone B311, the manufacturing process, and its applications in various sectors.

Manufacturing Process

The production of Lithopone B311 involves several chemical processes designed to create a stable and high-quality pigment. The primary raw materials include zinc oxide (ZnO) and barium sulfate (BaSO4). These components undergo a precipitation reaction, wherein solutions containing zinc and barium ions react to form lithopone.

Typically, the process starts with the dissolution of zinc oxide in water followed by the introduction of barium sulfate. The pH levels and temperature are carefully controlled to facilitate the formation of the desired crystalline structure. The resulting compound is then filtered, washed, and dried to produce a fine, white powder Lithopone B311.

The factories producing this pigment typically utilize state-of-the-art technology to ensure quality control throughout the manufacturing process. Automation and sophisticated monitoring systems allow for precise adjustments to be made, which help maintain consistent product quality.

Quality Control and Standards

Lithopone B311 factories adhere to strict quality control measures and international standards. Techniques like X-ray fluorescence (XRF) and scanning electron microscopy (SEM) are commonly employed to analyze the chemical composition and particle size distribution of the pigment. This ensures that the end product not only meets regulatory requirements but also performs well in industrial applications.

lithopone b311 factories

Moreover, leading lithopone manufacturers are investing in sustainable practices to minimize their environmental impact. This includes reducing waste by reusing raw materials and implementing energy-efficient manufacturing processes. Such initiatives are becoming increasingly essential in industries where consumers are demanding environmentally friendly products.

Applications of Lithopone B311

Lithopone B311 is particularly valued for its versatility across various industries. In the paints and coatings sector, it is used as a white pigment due to its excellent hiding power and UV stability, making it ideal for both interior and exterior applications. The pigment is compatible with oil and water-based paints, enhancing their durability against weathering and fading.

In the plastics industry, Lithopone B311 serves as a brightening agent that helps improve the aesthetic appeal of plastic products. It is commonly used in the production of PVC, where its presence not only provides whiteness but also contributes to the thermal stability of the plastic, making the final product more durable.

Additionally, Lithopone B311 finds applications in the paper industry, where it enhances the brightness and opacity of paper products. It is often used in high-quality printing papers, allowing for vibrant color reproduction without compromising the paper's structural integrity.

Conclusion

The manufacturing of Lithopone B311 is a complex process that prioritizes quality and consistency. With factories employing advanced technologies and adhering to stringent quality standards, the pigment's versatility makes it a popular choice across various sectors. Its applications in paints, plastics, and paper underline the importance of Lithopone B311 in enhancing product performance and aesthetic appeal.

As industries continue to evolve, the demand for high-quality pigments like Lithopone B311 is expected to remain robust. Furthermore, a growing emphasis on sustainability will likely shape the future landscape of its production, pushing factories to innovate and adapt their practices to meet both market needs and environmental responsibilities. The continuing advancements in manufacturing, combined with the inherent properties of Lithopone B311, indicate a bright future for this essential industrial material.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025