Dec . 11, 2024 12:13 Back to list

lithopone b301 b311 zns.baso4 factory

Lithopone B301 and B311 A Study of Their Significance in Industrial Applications

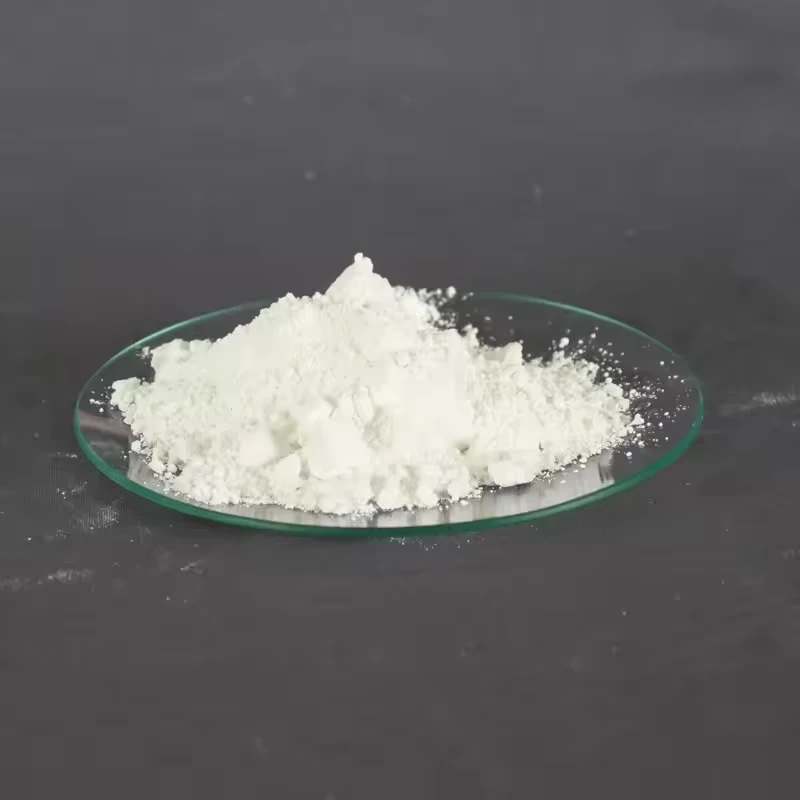

Lithopone is a white pigment that has been widely used in various applications due to its excellent opacity and bright whiteness. It is primarily made from a mixture of zinc sulfide (ZnS) and barium sulfate (BaSO₄). Two common grades of lithopone are B301 and B311, each with unique properties that make them suitable for different industrial applications. Understanding these grades, their manufacturing process, and their benefits can help industries choose the right materials for their needs.

Production Process

Lithopone is produced through a chemical reaction between zinc sulfate and barium sulfide, resulting in zinc sulfide and barium sulfate. The production of Lithopone B301 involves a balanced proportion of these components to achieve specific physical properties, particularly in terms of brightness and consistency. In contrast, B311 is formulated to enhance specific attributes, such as finer particle size or improved dispersion characteristics.

These compounds undergo a meticulous manufacturing process that usually includes precipitation, washing, and drying. The quality control measures during production are essential to ensure that the final product meets industry standards for consistency and purity. Manufacturers typically cover these processes in state-of-the-art facilities, which enable them to produce high-quality lithopone pigments efficiently.

Characteristics and Applications

Lithopone B301 is known for its excellent hiding power and is often used in applications such as paints, coatings, and plastics. Its high opacity makes it an ideal choice for white paints and high-quality coatings, where coverage and aesthetic appeal are paramount. The pigment's ability to resist ultraviolet (UV) light degradation also enhances its longevity, making it favorable for outdoor applications.

On the other hand, Lithopone B311 features a slightly different composition and fineness, providing better dispersion in liquid mediums. This quality is particularly beneficial in manufacturing, where an even distribution of pigment can significantly influence the final product's texture and appearance. B311 is frequently employed in the production of printing inks, adhesives, and sealants. Its compatibility with various polymers allows the grade to be used across a broad spectrum of materials, enhancing performance parameters such as durability and adhesion.

lithopone b301 b311 zns.baso4 factory

Environmental Considerations

As industries strive to adopt more sustainable practices, lithopone pigments stand out due to their environmental advantages. Unlike some synthetic organic pigments, lithopone is an inorganic compound, which often leads to lower environmental impact when disposed of, as it does not produce toxic byproducts. Additionally, the longevity of products using lithopone pigments can diminish the need for frequent repainting or reapplication, aligning with sustainability goals.

Market Trends and Future Prospects

With the increasing demand for high-performance coatings and environmentally friendly materials, the market for lithopone pigments, including B301 and B311, is on the rise. Innovations in manufacturing processes and formulations are expected to enhance the properties of these pigments further, making them suitable for a wider array of applications.

Additionally, the trend towards non-toxic and sustainable materials in consumer products is likely to drive the adoption of lithopone as an alternative to traditional pigments. As industries continue to look for sustainable solutions, the relevance of lithopone B301 and B311 will remain significant.

Conclusion

In conclusion, lithopone B301 and B311 play critical roles in various industrial applications, from coatings to inks. Their unique properties, coupled with sustainable production processes, make them desirable options in a constantly evolving market. As environmental considerations take center stage in manufacturing, the versatility and performance of lithopone pigments will ensure their continued relevance in the years to come. Industries looking to enhance their product offerings without compromising on quality can benefit greatly from incorporating lithopone into their production lines.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025