Nov . 10, 2024 21:55 Back to list

Lithopone B301 B311 Suppliers and Manufacturers for Quality Pigment Solutions

Understanding Lithopone The B301 and B311 Variants

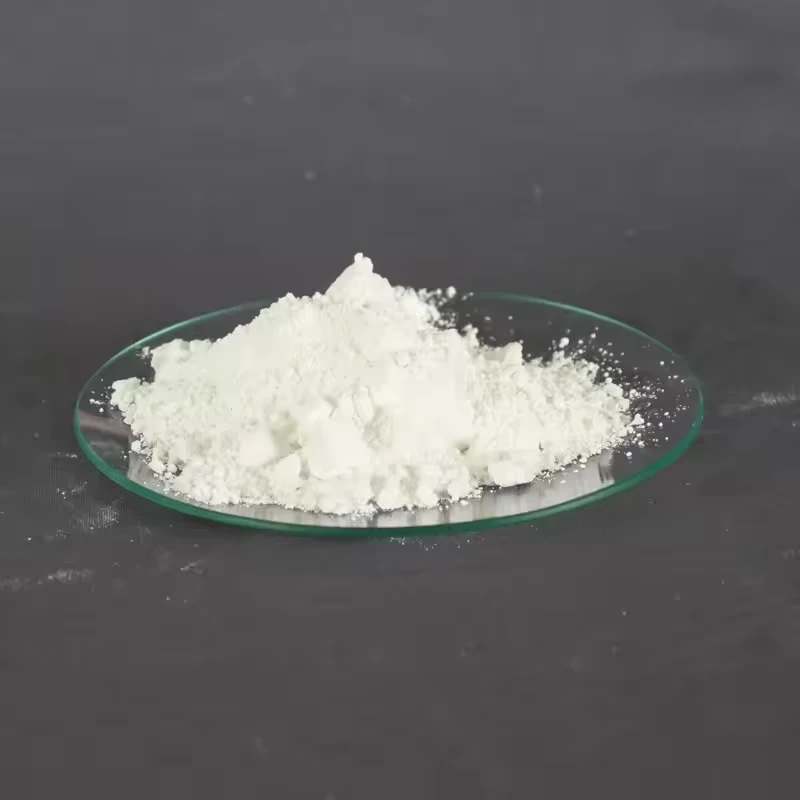

Lithopone is a white pigment that has been widely used in various applications, including paints, coatings, plastics, and rubber products. Composed primarily of zinc sulfide and barium sulfate, it offers unique properties that make it an excellent choice for the manufacturing of vibrant and durable products. Among the several grades of lithopone available in the market, B301 and B311 are two noteworthy variants that have gained prominence due to their specific characteristics and applications.

The Composition of Lithopone

Lithopone is formed through the precipitation of zinc sulfide and barium sulfate. The resultant compound is known for its excellent opacity, brightness, and excellent resistance to discoloration. Compared to traditional white pigments like titanium dioxide, lithopone tends to be less expensive while still offering commendable performance. However, its use has decreased somewhat with the advent of synthetic alternatives, although it still holds a niche in certain sectors.

B301 and B311 Variants

The B301 and B311 grades of lithopone are differentiated based on their specific composition and resulting properties.

- B301 This variant typically contains a higher percentage of barium sulfate which gives it superior opacity and durability. It is known for excellent weather resistance, making it particularly suitable for outdoor applications. B301 is often used in construction materials and exterior paints where longevity and color stability are crucial.

- B311 On the other hand, B311 is characterized by a different ratio of components that results in a softer white tone. This variant is valued for its consistency and ability to mix well with other pigments. It finds application in industries that require delicate color matching and fine finishes, such as premium paints and coatings.

Manufacturing Processes

The production of lithopone, including the B301 and B311 versions, involves several meticulous steps. The process starts with the reaction of zinc oxide and barium sulfide, which upon precipitation forms the required compounds. Manufacturers often employ advanced techniques to control the particle size and distribution, ensuring that the final product meets the required specifications.

lithopone b301 b311 manufacturer

Experts in the field understand that the manufacturing process can significantly influence the performance of the final pigment. For instance, variations in temperature and pressure during synthesis can lead to differences in opacity, brightness, and ease of dispersibility.

Applications in Industry

Lithopone, particularly the B301 and B311 grades, is extensively used in various industries

1. Paints and Coatings Both variants are favored in the paint industry for their excellent hiding power and whiteness. B301 is more common in exterior applications, while B311 is often chosen for interior products owing to its smooth finish and compatibility with other components.

2. Plastics Lithopone's thermal stability and UV resistance make it suitable for use in plastic products, ensuring that colors remain vibrant even under harsh conditions.

3. Rubber Products The rubber industry also benefits from lithopone, utilizing it to enhance the durability and aesthetic appeal of rubber goods.

4. Cosmetics In recent years, lithopone has found its way into cosmetic formulations as a safe and effective colorant, thanks to its non-toxic nature.

Conclusion

In summary, lithopone remains a critical component in various manufacturing processes, with the B301 and B311 variants offering specific benefits that cater to different industrial needs. Understanding their distinct properties allows manufacturers to make informed choices that enhance the performance and longevity of their products. As industries continue to evolve, the demand for quality pigments like lithopone is likely to persist, cementing its role in modern manufacturing.

For those seeking a reliable manufacturer of lithopone B301 and B311, it is crucial to assess their production capabilities, quality control measures, and adherence to environmental standards, ensuring that the pigments meet not only performance requirements but also sustainability goals.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025