Nov . 19, 2024 16:33 Back to list

Lithopone and Titanium Dioxide Production for High-Quality Pigments and Coatings

The Landscape of Lithopone and Titanium Dioxide Manufacturing

In the realm of industrial pigments and coatings, lithopone and titanium dioxide (TiO2) stand out as two prominent substances, each with unique properties and applications. As manufacturers continue to innovate, understanding the characteristics, production processes, and market dynamics of these materials has never been more critical.

What is Lithopone?

Lithopone is a white pigment composed of a mixture of zinc sulfide (ZnS) and barium sulfate (BaSO4). Developed in the late 19th century, it is primarily used in paints, plastics, and paper due to its excellent opacity and brightness. Lithopone is particularly valued for its ability to reflect light and resist yellowing over time, making it ideal for various indoor and outdoor applications.

Manufacturing lithopone involves a few critical steps. The primary raw materials, zinc sulfate and barium sulfide, are precipitated together to form lithopone. The product is then dried and milled to achieve the desired particle size. However, the production of lithopone is less common today compared to titanium dioxide, primarily due to TiO2’s superior performance and versatility.

Titanium Dioxide The Industry Leader

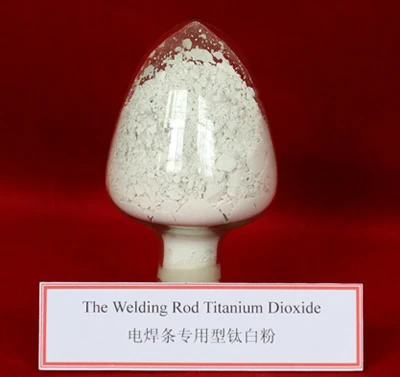

Titanium dioxide is often considered the gold standard for white pigments in the industry. This compound is renowned for its outstanding brightness, high refractive index, and remarkable opacity. As a result, it is extensively used in coatings, plastics, cosmetics, and even food products. Its ability to absorb ultraviolet (UV) light also makes it a key ingredient in sunscreen formulations.

lithopone and titanium dioxide manufacturer

The manufacturing process of titanium dioxide generally follows one of two methods the sulfate process or the chloride process. The sulfate process involves treating titanium ore (often ilmenite) with sulfuric acid, while the chloride process uses chlorine gas to produce titanium tetrachloride, which is subsequently oxidized to yield TiO2. Both methods have their advantages; the chloride process tends to produce higher purity titanium dioxide but may require more sophisticated equipment.

Market Trends and Outlook

The global demand for both lithopone and titanium dioxide has been shaped by various market trends. While titanium dioxide continues to dominate due to its performance characteristics and wider range of applications, lithopone remains relevant in niche markets. The growth of eco-friendly products has also prompted manufacturers to explore sustainable practices in the production of these pigments.

As environmental regulations tighten and consumer preferences shift towards more sustainable options, manufacturers are innovating in their production processes. For instance, recycling waste materials and reducing emissions are becoming focal points in the pigment industry.

Conclusion

Both lithopone and titanium dioxide play crucial roles in numerous industries. While titanium dioxide leads in performance and demand, lithopone maintains its significance in specific applications. Manufacturers must stay informed about market trends, production techniques, and sustainability practices to remain competitive in this evolving landscape. As technology advances and consumer preferences shift, the future of these two pigments will undoubtedly be influenced by the quest for efficiency and eco-friendly practices.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025