Sep . 12, 2024 15:47 Back to list

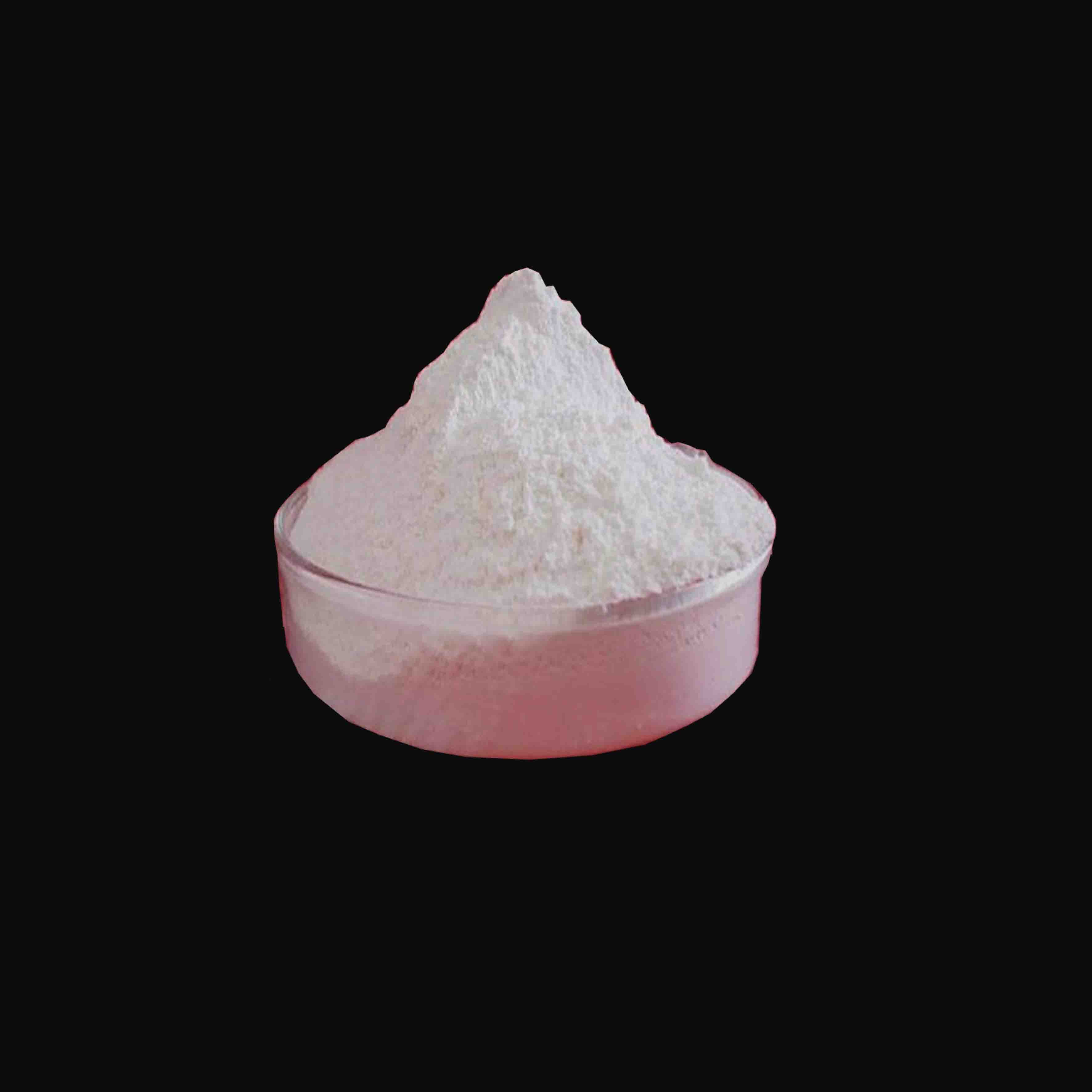

Lithopone Price Suppliers - High-Quality Lithopone at Competitive Rates

Understanding Lithopone Pricing and Suppliers

Lithopone, a white pigment composed primarily of zinc sulfide and barium sulfate, has been widely utilized in various industries, notably in paints, coatings, plastics, and rubber production. Its popularity stems from its excellent opacity, high brightness, and excellent weather resistance, making it an appealing alternative to titanium dioxide in certain applications. However, the pricing of lithopone can vary significantly, influenced by factors such as raw material costs, production techniques, and market demand.

Factors Influencing Lithopone Pricing

1. Raw Material Costs The primary components of lithopone—zinc and barium—are subject to price fluctuations based on supply and demand dynamics in global markets. Any increase in the costs of these raw materials directly impacts the overall pricing of lithopone products. Suppliers often adjust their prices to reflect these changes, ensuring they maintain profitability while remaining competitive.

2. Production Techniques Lithopone is manufactured through various processes, including the coprecipitation method and the reaction of zinc and barium compounds. The efficiency and technology used in production can influence the cost of the final product. Advances in production technology may lead to cost reductions, which could be reflected in more competitive pricing for lithopone from some suppliers.

3. Market Demand The demand for lithopone in various industries is another critical factor affecting pricing. As markets evolve, the need for high-quality pigments in applications such as automotive finishes, construction materials, and consumer goods can lead to increased demand. In turn, heightened demand may drive prices up, particularly if suppliers struggle to keep pace with production requirements.

lithopone price suppliers

4. Geographical Factors Supply chains are often impacted by logistical considerations, including location, transportation costs, and import/export regulations. Suppliers located closer to key markets may have an advantage in pricing due to lower shipping expenses and supply chain efficiencies.

Finding Reliable Suppliers

When looking for lithopone suppliers, quality assurance and reliability are paramount. Buyers should consider not only price but also the supplier's reputation in the industry, the quality of their products, and their customer service. There are numerous suppliers globally, each offering different grades and formulations of lithopone. It is often beneficial for businesses to establish long-term relationships with suppliers who understand their specific needs and can provide consistent quality at competitive rates.

Conclusion

The price of lithopone is influenced by a multitude of factors, including raw material costs, production methods, market demand, and geographical considerations. As industries continue to innovate and evolve, suppliers will need to adapt accordingly. For businesses relying on lithopone, staying informed about market trends and establishing partnerships with key suppliers can significantly impact overall product quality and cost-effectiveness. By understanding the underlying dynamics of lithopone pricing, buyers can make more informed decisions, ensuring they access high-quality products that meet their operational needs.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025