Dec . 16, 2024 12:27 Back to list

High-Quality Tio2 Production from ISK Factory for Superior Performance and Sustainability

The ISK TiO2 Factory Pioneering Sustainable Titanium Dioxide Production

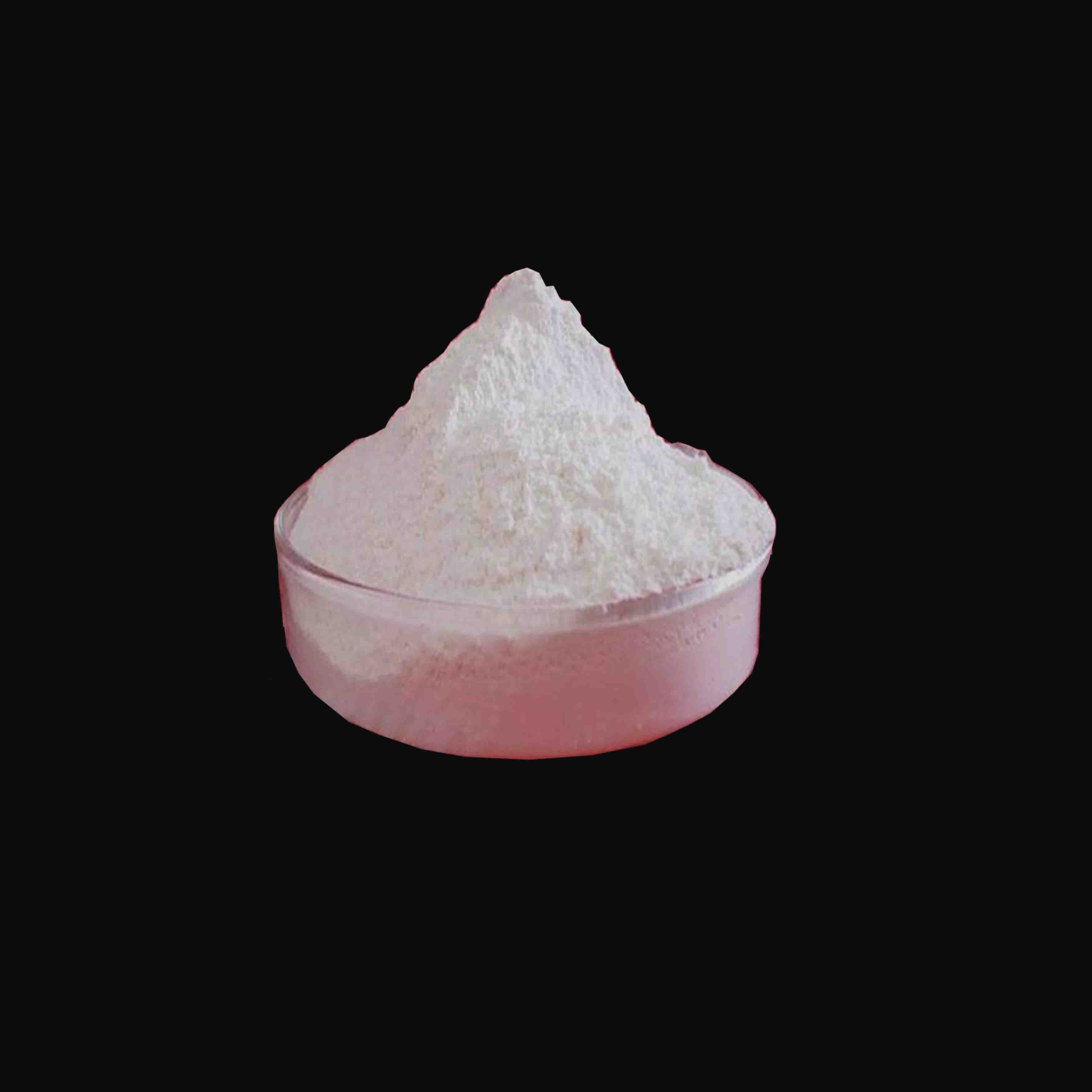

In recent years, the demand for titanium dioxide (TiO2) has surged across various industries, including paints, coatings, plastics, and cosmetics. Its remarkable properties, such as high opacity, brightness, and UV resistance, make it a critical component in these sectors. However, the environmental impact associated with titanium dioxide production has raised serious concerns. Addressing these issues, the ISK TiO2 Factory stands as a beacon of innovation, striving to create a sustainable model for TiO2 manufacturing.

The ISK TiO2 Factory Pioneering Sustainable Titanium Dioxide Production

One of the key features of the ISK TiO2 Factory is its emphasis on sustainability. The factory uses a chloride process for TiO2 production, which is considered more environmentally friendly compared to the traditional sulfate process. The chloride method reduces the generation of harmful byproducts and decreases overall resource consumption. By utilizing this process, ISK is not only contributing to a less polluted environment but also paving the way for more industries to adopt cleaner production practices.

isk tio2 factory

Moreover, the ISK TiO2 Factory has invested significantly in water recycling systems. Given that water is a critical resource in chemical processes, the factory implements sophisticated filtration and purification systems to reclaim and reuse water. This initiative drastically reduces the factory's reliance on freshwater resources and minimizes the potential for water pollution, aligning with global efforts to conserve water in industrial applications.

Energy efficiency is another focal point of the ISK TiO2 Factory's operations. The facility is equipped with energy-efficient machinery and employs innovative practices that minimize energy consumption. By leveraging renewable energy sources, such as solar power, ISK is taking significant strides towards achieving a greener production model. This commitment to energy sustainability not only lowers operational costs but also mitigates the factory's carbon footprint, contributing to a more sustainable future.

The workforce at the ISK TiO2 Factory is trained to prioritize safety and environmental awareness. Employees undergo rigorous training programs that emphasize the importance of sustainable practices and environmental responsibility. This culture of sustainability extends beyond the factory walls, encouraging employees to advocate for eco-friendly practices in their personal lives as well. By fostering this mindset, ISK empowers its workforce to be agents of change in the pursuit of a sustainable industry.

In conclusion, the ISK TiO2 Factory demonstrates that it is possible to align industrial production with environmental stewardship. Through innovative processes, resource efficiency, and a committed workforce, ISK sets a high standard for TiO2 manufacturing. As industries continue to grapple with the need for sustainable practices, the ISK TiO2 Factory serves as a model, illustrating how businesses can thrive while making meaningful contributions to environmental protection. This commitment to sustainability not only enhances the company’s reputation but also ensures a better future for the planet and generations to come. As the world transitions towards a more sustainable economy, ISK is poised to lead the charge in the titanium dioxide industry.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025