Nov . 20, 2024 06:17 Back to list

hitox tio2 manufacturer

Understanding Hitox TiO2 Manufacturer A Key Player in Titanium Dioxide Production

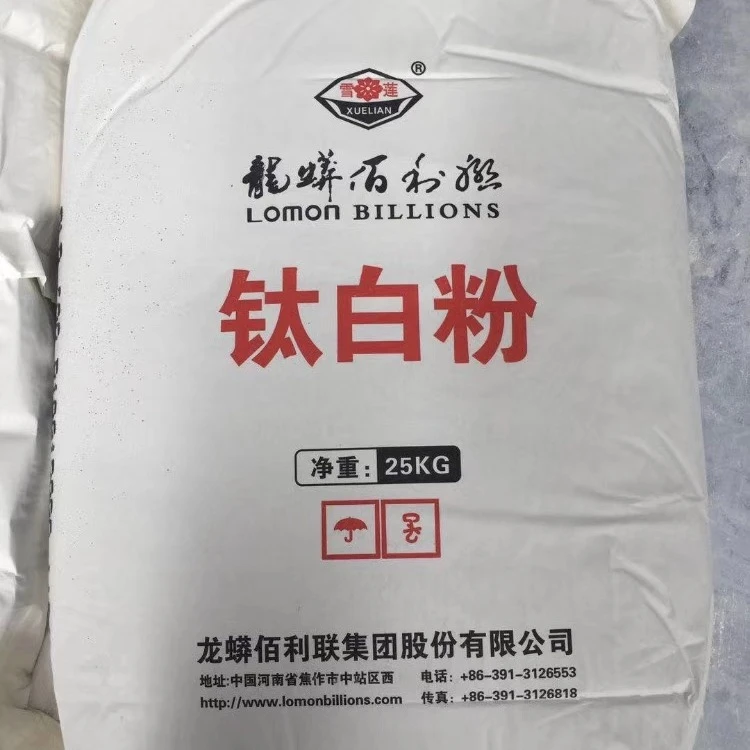

Titanium dioxide, commonly referred to as TiO2, is a versatile and widely used compound recognized for its remarkable properties, including opacity and brightness. It has found extensive applications across various industries, from paints and coatings to plastics and food. In this context, Hitox emerges as a significant manufacturer specializing in TiO2, providing high-quality products that cater to diverse market needs.

What is Hitox?

Hitox is a prominent manufacturer in the field of titanium dioxide production, known for its commitment to quality, innovation, and sustainability. The company utilizes advanced production techniques and state-of-the-art technology to ensure that its TiO2 products meet the stringent requirements of its customers. Hitox has established itself as a reliable supplier, focusing on delivering value through its superior product offerings and exceptional customer service.

The Importance of Titanium Dioxide

Titanium dioxide is essential in several applications due to its unique properties. One of its primary uses is in the paint and coatings industry, where it is valued for its ability to provide excellent coverage, durability, and weather resistance. It is also widely used in plastics, cosmetics, and even food products as a colorant and opacity agent. The demand for titanium dioxide has been on the rise due to these applications, making manufacturers like Hitox crucial players in the supply chain.

Hitox’s Manufacturing Capabilities

Hitox employs cutting-edge techniques in its manufacturing processes, ensuring high purity and consistency in its TiO2 products. The company follows environmentally friendly practices, incorporating sustainable methods to minimize waste and reduce emissions. This commitment not only enhances the quality of the products but also aligns with global sustainability goals, making Hitox a preferred choice for environmentally conscious companies.

hitox tio2 manufacturer

The production process at Hitox involves careful selection of raw materials, stringent quality control measures, and continuous research and development efforts. The company invests significantly in technological advancements to improve production efficiency and product performance. By focusing on innovation, Hitox can stay ahead of industry trends and meet the evolving demands of its clients.

Product Range and Applications

Hitox offers a diverse range of TiO2 products suitable for various applications. Its pigment-grade titanium dioxide is widely used in the paint and coatings industry, while its specialty-grade TiO2 finds applications in plastics and other advanced materials. Additionally, Hitox is actively involved in the development of nanostructured titanium dioxide products, which have potential applications in photocatalysis, self-cleaning surfaces, and solar energy conversion.

The company’s dedication to producing high-quality titanium dioxide has garnered a loyal customer base across many sectors. Clients benefit from Hitox’s expertise in formulating tailor-made solutions that meet specific needs, enhancing their product efficacy and market competitiveness.

Commitment to Sustainability

In today’s world, sustainability is a critical concern for both manufacturers and consumers. Hitox recognizes the importance of minimizing its environmental footprint and is committed to implementing sustainable practices throughout its operations. From sourcing raw materials to the final stages of production, the company strives to reduce energy consumption and waste generation, contributing to a cleaner, greener future.

Conclusion

As a leading manufacturer of titanium dioxide, Hitox plays a vital role in supplying high-quality TiO2 products to various industries. Through its innovative manufacturing processes, commitment to sustainability, and focus on customer satisfaction, Hitox has positioned itself as a trustworthy partner in the global market. As demand for titanium dioxide continues to grow, the contributions of manufacturers like Hitox will be increasingly important in shaping the future of the industry.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025