Nov . 19, 2024 08:45 Back to list

Gravimetric Assessment of Titanium Dioxide Production Techniques and Their Analytical Implications

Gravimetric Analysis of Titanium Dioxide A Comprehensive Overview for Manufacturers

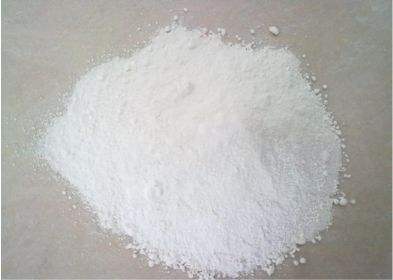

Titanium dioxide (TiO2) is a widely used white pigment, known for its brightness and high refractive index. It serves critical roles in various industries, including paint, plastics, cosmetics, and food. The quantification and analysis of titanium dioxide are essential for manufacturers to ensure quality control and compliance with regulatory standards. One of the most reliable methods for the analysis of TiO2 is gravimetric analysis, a technique that determines the quantity of a substance based on its mass.

Understanding Gravimetric Analysis

Gravimetric analysis is a quantitative analytical technique that involves the conversion of a chemical species into a stable, solid product, which is then weighed. This technique is highly accurate and has been employed for centuries in analytical chemistry. The core principles of gravimetric analysis consist of precipitation, filtration, drying, and weighing.

In the context of titanium dioxide, manufacturers often use gravimetric analysis to assess the purity and concentration of TiO2 in various products. This not only ensures the quality of raw materials but also helps in maintaining consistency in the final product.

The Process of Gravimetric Analysis for TiO2

The gravimetric analysis process for titanium dioxide can be divided into several steps

1. Sample Preparation A sample of the titanium dioxide material is taken, which may include a mixture of precipitates or impurities. The sample is then prepared for analysis by dissolving it in an appropriate solvent, typically nitric acid or hydrochloric acid.

2. Precipitation To isolate the titanium ions from the sample matrix, a precipitation agent, such as ammonium sulfate or ammonium hydroxide, is added. This results in the formation of titanium hydroxide precipitate (Ti(OH)4). The reaction needs to be controlled to ensure complete precipitation, which may involve adjusting pH or temperature.

3. Filtration and Drying Once the precipitate is formed, it is filtered using a suitable filter paper or membrane. After filtration, the precipitate is washed to remove any impurities or unreacted species to ensure accuracy in weighing. The filtered precipitate is then dried in an oven at a specific temperature to remove moisture. Drying is a crucial step, as any remaining water will affect the weight measurement.

gravimetric analysis of titanium dioxide manufacturer

4. Weighing The dried precipitate, which now consists primarily of titanium dioxide, is weighed using an analytical balance. The weight obtained can be used to calculate the concentration of TiO2 in the original sample based on stoichiometric principles.

5. Calculations and Results Interpretation Based on the mass of the TiO2 precipitate and the initial mass of the sample, manufacturers can calculate the gravimetric percentage of titanium dioxide. These results are then compared against standard specifications to ensure quality.

Importance for Manufacturers

For manufacturers, gravimetric analysis of titanium dioxide is crucial for several reasons

- Quality Control Ensuring consistent quality of TiO2 across batches is vital for product performance. Gravimetric analysis provides reliable data for quality assurance. - Regulatory Compliance Many industries are subject to strict regulatory standards that dictate the allowable limits for various substances. Gravimetric analysis contributes to compliance with these regulations by accurately quantifying TiO2 content.

- Cost Efficiency Accurate determination of TiO2 content can aid manufacturers in optimizing formulations, reducing waste, and controlling costs.

- Research and Development In R&D, the purity and concentration of titanium dioxide are fundamental parameters when developing new products or improving existing formulations. Gravimetric analysis provides a solid foundation for these efforts.

Conclusion

Gravimetric analysis stands out as a dependable method for quantifying titanium dioxide in manufacturing processes. Its high precision, reliability, and cost-effectiveness make it an invaluable tool for quality control, regulatory compliance, and research. As industries continue to innovate and evolve, the importance of accurate measurement and analysis, such as gravimetric techniques, will remain integral to the success of titanium dioxide manufacturers. Ultimately, mastery of this analytical approach not only enhances product quality but also fosters confidence among consumers and stakeholders.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025