Nov . 07, 2024 16:39 Back to list

Manufacturers of Titanium Dioxide Production and Their Processes Explained

The Formation of Titanium Dioxide Insights into Manufacturers and Processes

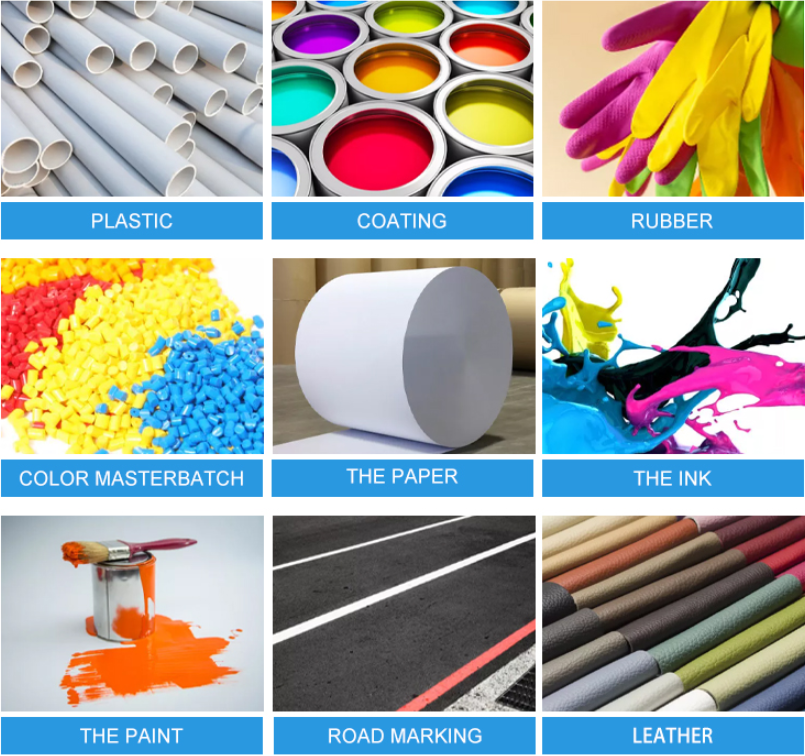

Titanium dioxide (TiO2) is a white pigment widely used in various industries, including paints, coatings, plastics, paper, and cosmetics. Its exceptional whiteness, brightness, and opacity, along with its high resistance to UV radiation, make it the pigment of choice for manufacturers globally. The formation of titanium dioxide occurs through various chemical processes, primarily the sulfate and chloride processes, each employed by different manufacturers depending on the desired qualities of the final product.

Overview of Titanium Dioxide Production

The global titanium dioxide market is driven by the increasing demand for high-performance pigments that offer superior durability and aesthetic appeal. The production of titanium dioxide typically begins with the extraction of titanium ore, notably ilmenite or rutile, mined from the earth. The ore is then processed to extract titanium, which is converted into titanium dioxide through either the sulfate or chloride process.

The Sulfate Process

The sulfate process involves treating ilmenite ore with sulfuric acid, resulting in the leaching of titanium. The process yields a titanium sulfate solution, which is then hydrolyzed to form titanium dioxide pigments. This method is preferred by manufacturers who seek to produce a low-cost titanium dioxide product, but it may lead to the generation of large amounts of waste products. As such, environmental regulations play a crucial role in shaping the processes used by sulfate-based manufacturers, pushing them to adopt more sustainable practices.

While the sulfate process has been the traditional method of titanium dioxide production, it can have a significant environmental impact due to the wastage of by-products and the high energy requirements. Manufacturers are therefore increasingly investing in waste-reduction technologies and sustainable practices to minimize their ecological footprint.

The Chloride Process

formation of titanium dioxide manufacturers

In contrast, the chloride process utilizes rutile ore and involves the conversion of titanium ore into titanium tetrachloride (TiCl4) through chlorination. This compound is then purified through distillation and converted into titanium dioxide via oxidation. The chloride process is known for producing high-quality, high-performance titanium dioxide with lower impurities, which is particularly advantageous for applications in high-end paints, coatings, and plastics.

Manufacturers favoring the chloride process often position themselves in the premium market segment, targeting customers who require top-tier products with specific characteristics. Although the chloride process is generally more capital-intensive and requires more sophisticated technology, the resulting titanium dioxide has superior properties, such as better color retention and brightness, which attract a loyal customer base.

Global Manufacturers and Trends

Several key players dominate the titanium dioxide market, including companies like DuPont, Huntsman Corporation, and Tronox. These manufacturers are at the forefront of innovation, constantly seeking ways to enhance quality while reducing costs. With the increasing focus on sustainability, firms are investing in research and development to create more efficient processes that minimize environmental impact.

The competition among titanium dioxide manufacturers is also reflected in their ability to adapt to changing market demands. As industries push for safer and more eco-friendly products, manufacturers are striving to meet these needs by developing titanium dioxide grades that are safer for the environment and the end-users.

Additionally, the rising popularity of titanium dioxide in non-pigment applications, such as in the production of photocatalysts or as a catalyst support, is expanding opportunities for manufacturers. This diversification allows companies to leverage their existing production capabilities while exploring new markets.

Conclusion

The formation of titanium dioxide is a complex interplay of extraction, processing, and technological innovation. As manufacturers navigate through the challenges of cost, quality, and sustainability, the titanium dioxide industry continues to evolve. With increasing scrutiny on environmental impact and a push toward more sustainable production methods, companies are compelled to innovate and adapt. The future of titanium dioxide production holds promising potential as manufacturers strive to balance profitability with responsibility, ensuring that this essential material remains a cornerstone of many industries while addressing the growing demands of an environmentally conscious market.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025