Aug . 13, 2024 10:34 Back to list

Exploring the Key Players in the Titanium Dioxide Manufacturing Industry and Their Global Impact

The Growing Market of Titanium Dioxide Factories

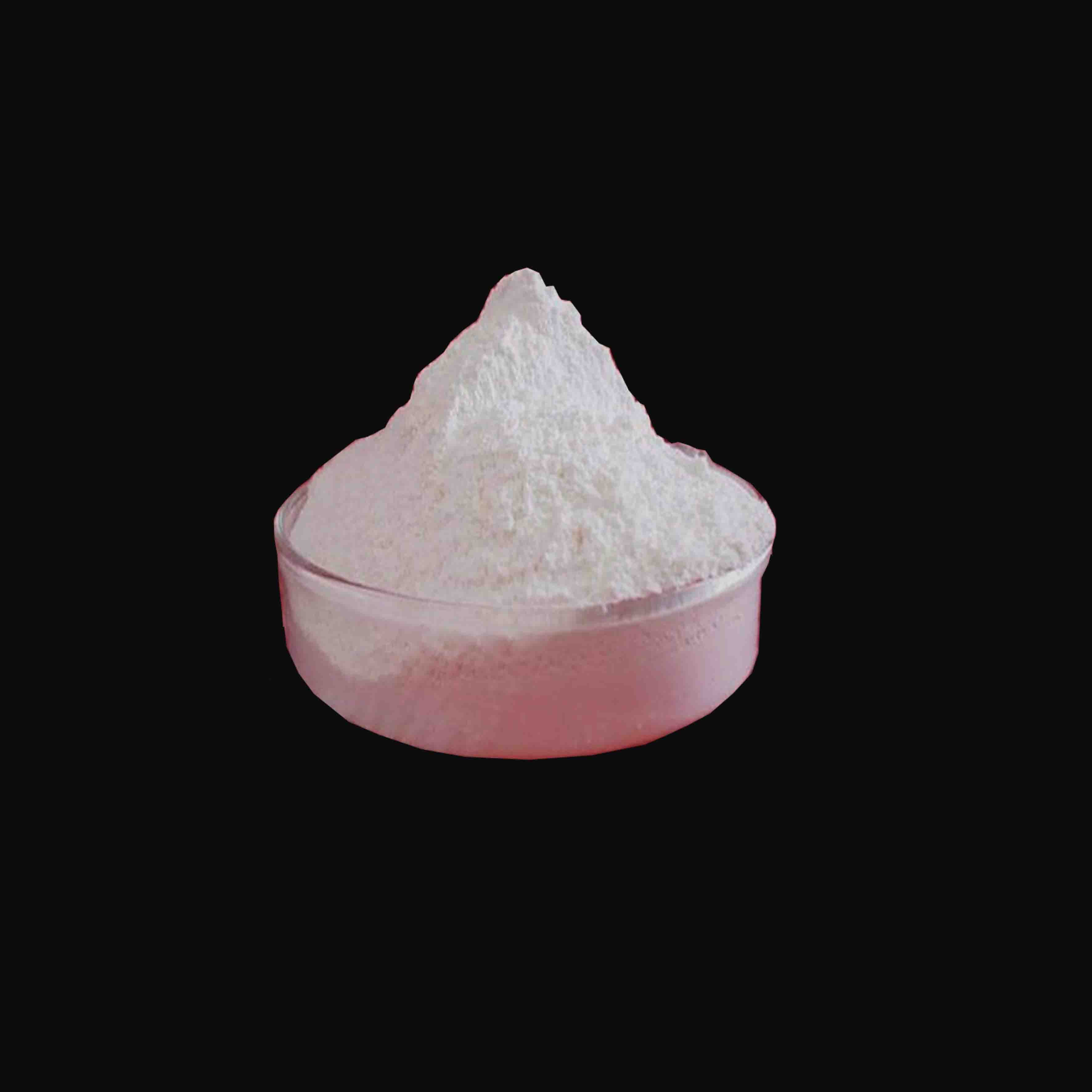

Titanium dioxide, often referred to as TiO2, is a widely used white pigment due to its high opacity, brightness, and durability. It plays a crucial role in various industries, including paints, coatings, plastics, and cosmetics. With the increasing demand for high-quality pigments, the market for titanium dioxide factories has been expanding rapidly. This article explores the significance, manufacturing processes, and future prospects of titanium dioxide factories.

Significance of Titanium Dioxide

The importance of titanium dioxide can be attributed to its unique properties. As one of the most effective white pigments, TiO2 provides excellent coverage, UV protection, and resistance to discoloration. Its versatility allows it to be incorporated into an array of products, from everyday consumer goods to industrial applications. The paint and coatings industry, for instance, relies heavily on TiO2 to offer stability and longevity to its products.

Aside from aesthetics, titanium dioxide is also finding applications in advanced technologies. It is being used in photocatalysis for environmental purification and in sunscreen formulations due to its ability to block harmful UV rays. This broad range of applications has fueled the demand for titanium dioxide, thereby incentivizing the establishment of more manufacturing facilities.

Manufacturing Processes of Titanium Dioxide

Titanium dioxide is produced primarily through two methods the sulfate process and the chloride process.

1. Sulfate Process This method involves treating ilmenite (iron titanium oxide) with sulfuric acid to produce titanium sulfate, which is subsequently hydrolyzed to yield titanium dioxide. The sulfate process produces lower-grade TiO2 but is often more cost-effective for certain low-end applications.

2. Chloride Process This involves converting titanium ore into titanium tetrachloride, which is then oxidized to produce high-purity titanium dioxide. The chloride process is favored in industries that demand superior quality and brightness, as it yields a finer product with less contamination.

jual titanium dioxide factories

Both methods have their unique advantages and challenges, leading many factories to choose based on the quality requirements of their target market. Environmental considerations play a significant role in the decision-making process, as both processes have varying impacts on the ecosystem.

Challenges and Trends in the Industry

The titanium dioxide industry faces several challenges, including fluctuating raw material prices and environmental regulations. Factories must adapt to strict regulations regarding emissions and waste management. This has led to increased investment in cleaner technologies and sustainable practices, such as recycling by-products and minimizing waste.

Another growing trend is the shift towards eco-friendly production methods. Consumers are becoming more aware of environmental issues, pushing manufacturers to adopt green practices. Advances in technology are also facilitating the development of innovative TiO2 products that meet the needs of different sectors while adhering to environmental standards.

Future Prospects

The future of titanium dioxide factories looks promising. As emerging economies continue to grow and urbanize, the demand for paints, coatings, and plastics will likely rise. Additionally, industries focusing on renewable energy and environmental solutions provide new market opportunities for TiO2.

The push for sustainable practices will also drive innovation within the industry. Factories are likely to invest in research and development to create advanced TiO2 products with enhanced performance characteristics. Furthermore, the emergence of circular economy principles may lead to practices aimed at recycling TiO2 and reducing resource consumption.

In conclusion, titanium dioxide factories play a vital role in the modern economy, serving as key providers of a substance that is integral to various industries. With the right investments in technology and a focus on sustainability, the future of the titanium dioxide market stands to thrive, meeting the evolving needs of consumers and industries alike.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025