Aug . 02, 2024 14:35 Back to list

Emerging Technologies in the Production of Nanosized Titanium Dioxide for Industrial Applications

The Rise of Nanosized Titanium Dioxide Factories

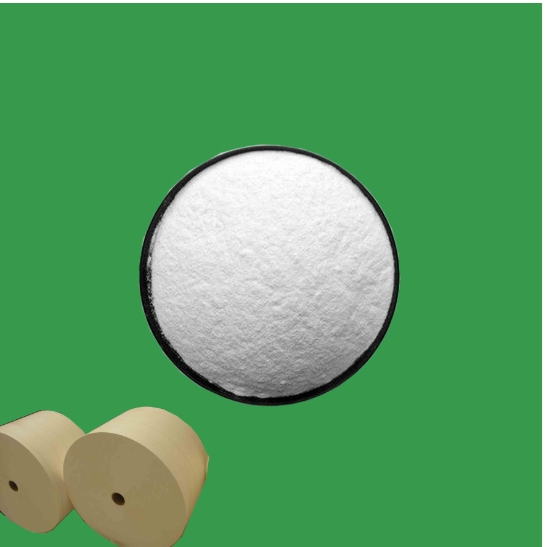

In recent years, the field of nanotechnology has witnessed a remarkable transformation, with nanosized titanium dioxide (TiO2) emerging as a pivotal player in various industries. This finely engineered material, characterized by its nanoscale dimensions (typically 1-100 nanometers), boasts unique properties that make it highly sought after in applications like photocatalysis, pigments, sunscreens, and environmental remediation. The establishment of nanosized titanium dioxide factories reflects the growing demand for this versatile compound and the technological advancements facilitating its production.

Titanium dioxide, a naturally occurring mineral, has been used historically as a white pigment in paints, coatings, and plastics. Its high refractive index and ultraviolet (UV) light absorption capacity make it an ideal additive for enhancing brightness and stability. However, the introduction of nanotechnology has revolutionized its applications. Nanosized TiO2 exhibits enhanced photocatalytic properties, meaning it can accelerate chemical reactions when exposed to light, a feature that is particularly beneficial for environmental applications like air and water purification.

The development of factories dedicated to producing nanosized titanium dioxide involves advanced manufacturing techniques such as sol-gel synthesis, chemical vapor deposition, and hydrothermal processes. These methods allow for the precise control over the particle size, morphology, and surface properties of TiO2, ensuring that the material meets the specific requirements of different applications. For instance, photocatalytic applications require TiO2 with high surface area to maximize reaction rates, while applications in cosmetics demand materials that are safe and effectively block UV radiation.

nanosized titanium dioxide factories

As more companies recognize the potential of nanosized TiO2, the demand for manufacturing plants specializing in its production has soared. These factories not only contribute to the economy by creating jobs and promoting technological advancements but also have implications for sustainability. Nanosized TiO2 is increasingly being used in products aimed at reducing environmental impact, such as photocatalytic coatings that can break down pollutants and self-cleaning surfaces that reduce the need for harsh cleaning agents.

Moreover, nanosized titanium dioxide plays a critical role in the quest for renewable energy solutions. Its application in solar cells, particularly in dye-sensitized solar cells, has garnered significant attention. By utilizing TiO2 in photoelectrochemical processes, researchers are working toward more efficient solar energy conversion methods, facilitating the transition to greener energy sources.

The establishment of nanosized titanium dioxide factories, however, is not without challenges. Environmental and health concerns associated with the production and use of nanoparticles continue to be a point of contention within the scientific community. Issues relating to the potential toxicity of nanosized materials and their impact on ecosystems need to be thoroughly addressed through rigorous research and regulatory frameworks.

In conclusion, the rise of nanosized titanium dioxide factories represents a crucial development in the landscape of nanotechnology and material science. While offering an array of applications that contribute to advancements in sustainability and efficiency, it is imperative that stakeholders remain vigilant about the environmental and health implications. With responsible management and continued innovation, nanosized titanium dioxide has the potential to become a cornerstone of numerous industries, paving the way for a more sustainable future.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025