Oct . 09, 2024 07:02 Back to list

Leading Manufacturers of E171 Titanium Dioxide for Superior Quality Products

The Landscape of Titanium Dioxide Manufacturing An Overview

Titanium dioxide (TiO2) is a crucial pigment and ingredient widely used across various industries, from paints and coatings to plastics, cosmetics, and food products. The growing demand for TiO2, propelled by its exceptional properties such as high refractive index and excellent opacity, has led to the emergence of numerous manufacturers around the globe. This article delves into the key players in TiO2 production, their manufacturing processes, and the trends shaping the industry.

Major Titanium Dioxide Manufacturers

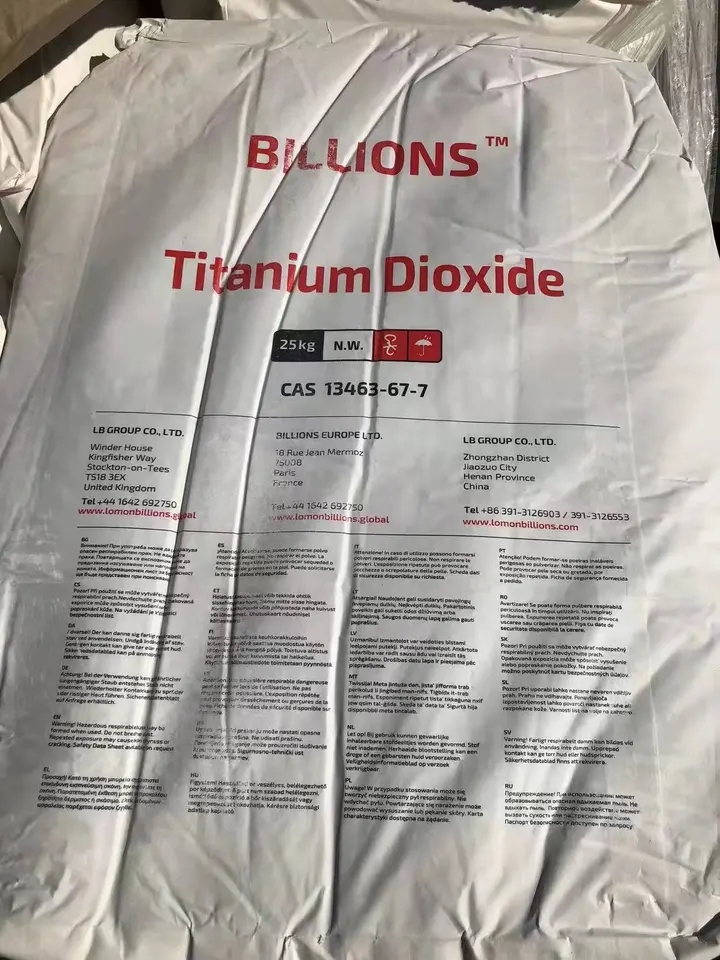

The titanium dioxide market is dominated by several key manufacturers, with companies like DuPont, Tronox, Chemours, and Huntsman standing out. These organizations have established significant production capacities and possess advanced technology that enhances the efficiency and quality of production processes.

1. DuPont As one of the pioneers in the field, DuPont has been at the forefront of TiO2 innovation. The company employs the chloride process for manufacturing TiO2, which is known for its reduced environmental impact compared to the traditional sulfate process.

2. Tronox A global leader in titanium production, Tronox operates several facilities worldwide. The company focuses on sustainability and technology to maintain a competitive edge in the market, striving to produce high-purity titanium dioxide with minimal waste.

3. The Chemours Company Spun off from DuPont, Chemours has carved a niche for itself as a major TiO2 manufacturer. The company’s Ti-Pure™ brand is a household name, especially in the paints and coatings sector. Chemours emphasizes sustainable practices and innovation in its production methods.

4. Huntsman Corporation In addition to its other chemical offerings, Huntsman produces TiO2 as part of its diverse portfolio. The company is known for its commitment to research and development, continually seeking to enhance the performance characteristics of its titanium products.

e 171 titanium dioxide manufacturers

Manufacturing Processes

The two primary methods of producing titanium dioxide are the sulfate process and the chloride process.

- Sulfate Process This traditional method involves treating titanium ores with sulfuric acid. While it has been widely used for decades, it generates significant waste and poses environmental challenges.

- Chloride Process The chloride route, on the other hand, involves refining titanium ore with chlorine gas to produce titanium tetrachloride, which is then oxidized to produce TiO2. This method is favored for its lower environmental impact and higher quality output.

Industry Trends

As the global demand for environmentally friendly products surges, titanium dioxide manufacturers are under pressure to adopt sustainable practices. Companies are investing in research to develop more efficient production methods that reduce energy consumption and environmental footprint. Additionally, the rise of nanotechnology is opening new avenues for TiO2 applications, particularly in the fields of electronics and renewable energy.

In conclusion, the titanium dioxide manufacturing industry is characterized by a mix of established giants and emerging players committed to innovation and sustainability. With continuous advancements in production technology and the increasing demand for high-performance materials, manufacturers are well-positioned to meet the evolving needs of various sectors. As we move forward, the focus on environmentally responsible manufacturing will likely shape the future landscape of titanium dioxide production.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025