Nov . 24, 2024 16:45 Back to list

Titanium Dioxide Pigment Supplier for High-Quality Dye Applications and Solutions

Understanding the Role of Dye Pigment Titanium Dioxide Suppliers in the Coatings Industry

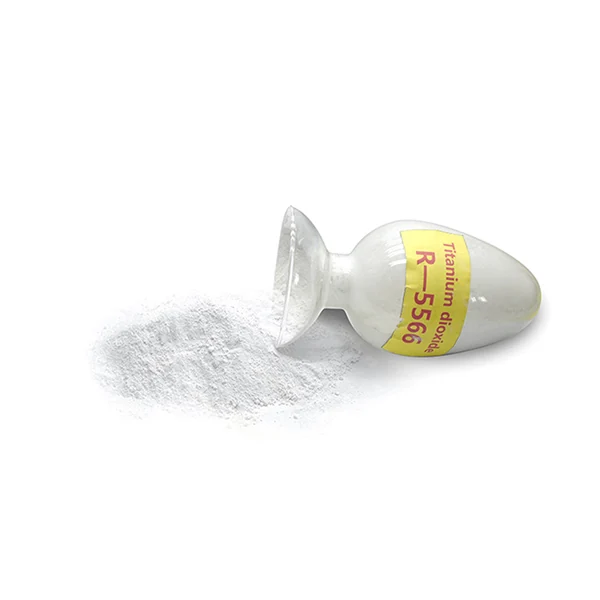

Titanium dioxide (TiO2) is one of the most widely used white pigments across various industries, particularly in coatings, plastics, and cosmetics. Its exceptional properties, such as high refractive index and excellent UV resistance, make it an essential component for achieving bright, durable, and opaque finishes. In this context, the role of dye pigment titanium dioxide suppliers becomes crucial.

The Importance of Titanium Dioxide

As a pigment, titanium dioxide is preferred for its outstanding opacity and light scattering abilities. It effectively enhances whiteness and brightness, improving the aesthetic appeal of products. In coatings, for example, it provides superior UV protection, ensuring that the applied films do not degrade in sunlight. This makes titanium dioxide indispensable for exterior paints and coatings, prolonging their lifespan and maintaining their visual integrity.

Types of Titanium Dioxide

There are primarily two grades of titanium dioxide used as pigments rutile and anatase. Rutile is the more commonly used form due to its superior opacity and weatherability. On the other hand, anatase is often used in applications where a lower cost is desired, but it does not perform as well in outdoor conditions. Suppliers typically offer both variants to cater to specific customer needs.

The Role of Suppliers

Dye pigment titanium dioxide suppliers play a pivotal role in the supply chain

. They not only provide the pigment in varying grades and formulations but also offer critical support and services that help manufacturers make the best choice for their applications. Suppliers often engage in rigorous quality control processes to ensure that the TiO2 they provide meets industry standards and customer specifications.dye pigment titanium dioxide supplier

Additionally, these suppliers support the formulation of products by providing technical expertise. They can advise on the optimal concentration of titanium dioxide needed to achieve desired results, which maximizes performance and minimizes costs. This technical know-how is invaluable, especially for businesses looking to innovate or improve existing formulations.

Sustainable Sourcing and Production

In recent years, there has been a growing emphasis on sustainability within the coatings industry. Dye pigment titanium dioxide suppliers are increasingly adopting environmentally friendly practices. This includes sourcing raw materials from sustainable sources and implementing processes that reduce the environmental impact of production.

Moreover, suppliers are also responding to the demand for eco-friendly products. Some suppliers are developing low-VOC (volatile organic compounds) formulations and exploring alternative routes for titanium dioxide production that mitigate waste and energy consumption. These efforts not only meet regulatory requirements but also align with the market trends towards greener products.

Supply Chain Challenges

Like many industries, the titanium dioxide market faces challenges, particularly related to supply chain disruptions. Factors such as raw material shortages, geopolitical tensions, and unexpected market fluctuations can impact the availability and pricing of titanium dioxide. Suppliers must remain agile, adapting their sourcing strategies and logistics to navigate these uncertainties. Building strong relationships with manufacturers and maintaining an open line of communication can help mitigate risks and ensure stable supply.

Conclusion

Dye pigment titanium dioxide suppliers are integral to the coatings industry, providing essential materials that enhance product performance and longevity. Their expertise in sourcing, production, and application of titanium dioxide is invaluable for manufacturers aiming to deliver high-quality coatings. As the industry continues to evolve towards sustainability, suppliers who prioritize eco-friendly practices and innovations will likely lead the market. Understanding the dynamics of this supply chain is key for businesses looking to thrive in a competitive landscape, making supplier selection a critical aspect of product development.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025