Nov . 29, 2024 14:09 Back to list

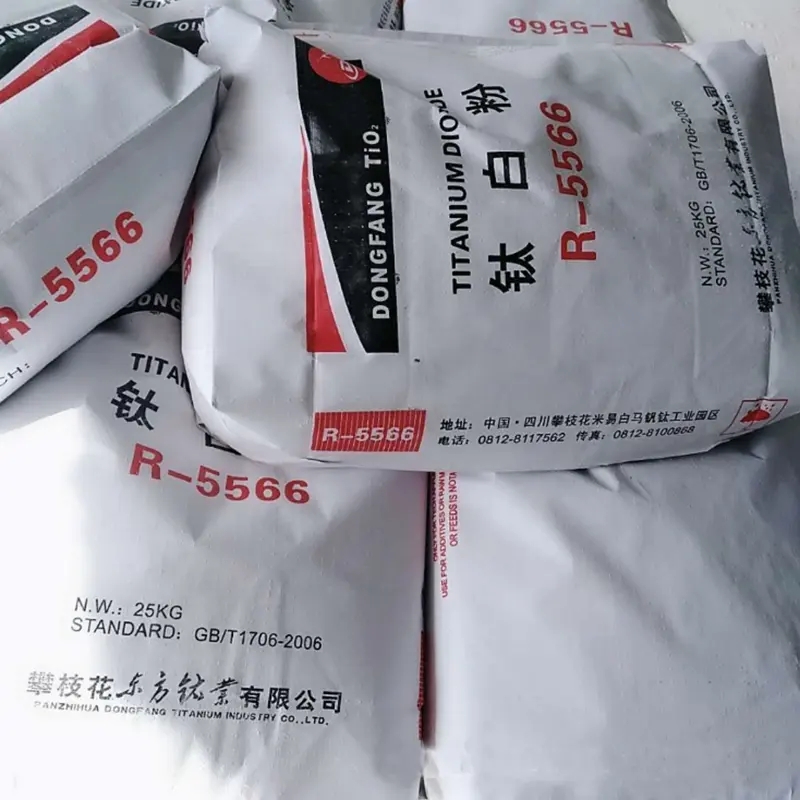

Top Manufacturers of Titanium Dioxide Products for Various Industries and Applications

The Role of Titanium Dioxide Manufacturers in Various Industries

Titanium dioxide (TiO2) is a widely used compound known for its exceptional brightness, high refractive index, and strong UV-resistant properties. These characteristics make it a preferred choice for various industries, including paint, plastics, paper, and cosmetics. The manufacturing of titanium dioxide has evolved significantly over the years, paving the way for innovation and sustainability. This article delves into the role of titanium dioxide manufacturers and their impact on multiple sectors.

Manufacturing Processes

Titanium dioxide is primarily produced using two processes the sulfate process and the chloride process. The sulfate process involves the reaction of titanium ore with sulfuric acid, leading to the formation of titanium dioxide. This method, while effective, generates a large volume of waste that can impact the environment if not managed properly.

In contrast, the chloride process uses titanium tetrachloride (TiCl4) as a precursor, which is then oxidized at high temperatures to produce titanium dioxide. This method is generally cleaner and produces a higher-quality product with lower impurities, making it favorable among manufacturers. As environmental regulations become stricter, many titanium dioxide manufacturers are transitioning towards the chloride process, thereby reducing their ecological footprint.

Market Applications

The wide range of applications for titanium dioxide in various industries underscores its importance. In the paint and coatings industry, TiO2 is used as a pigment due to its excellent opacity and brightness. Its ability to provide durability and resistance to weathering makes it crucial for exterior coatings. The demand for high-quality paints in the automotive and construction sectors further propels the growth of titanium dioxide manufacturers.

dioxide titanium manufacturers

In plastics, titanium dioxide serves both as a filler and a pigment. It enhances the mechanical properties of the material while providing whiteness and opacity to a variety of products, from food containers to automotive parts. The rise of the packaging industry, especially with the increased focus on sustainable solutions, has boosted the demand for titanium dioxide as manufacturers seek to improve the quality and durability of their products.

The cosmetics industry also heavily relies on titanium dioxide for its UV-blocking capabilities. Found in sunscreens and makeup products, titanium dioxide protects the skin from harmful UV rays while providing a smooth finish. As consumers become more aware of the importance of sun protection and skin health, the demand for titanium dioxide in cosmetics is expected to continue growing.

Sustainability and Innovation

As environmental stewardship becomes a paramount concern, titanium dioxide manufacturers are increasingly focusing on sustainable practices. This includes investing in cleaner production technologies, recycling waste materials, and developing eco-friendly products. Many manufacturers are exploring alternative raw materials and processes that minimize the environmental impact.

Moreover, innovation plays a critical role in the evolution of titanium dioxide. Research and development efforts are aimed at improving the efficiency of production methods, enhancing the performance of the final products, and expanding the applications of titanium dioxide. For instance, the development of nano-sized titanium dioxide particles has opened up new avenues in fields such as electronics, energy storage, and even medicine.

Conclusion

The role of titanium dioxide manufacturers is pivotal across various industries, and their contributions are set to grow as the demand for this versatile compound increases. By embracing sustainability and innovation, these manufacturers not only enhance their competitiveness but also ensure that they align with global environmental goals. As industries evolve and adapt to changing consumer preferences, titanium dioxide will undoubtedly remain a fundamental component, driving advancements and shaping the future of multiple sectors.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025