Oct . 30, 2024 13:01 Back to list

dioxide titanium cas 13463-67-7 suppliers

An Overview of Titanium Dioxide (CAS 13463-67-7) Suppliers

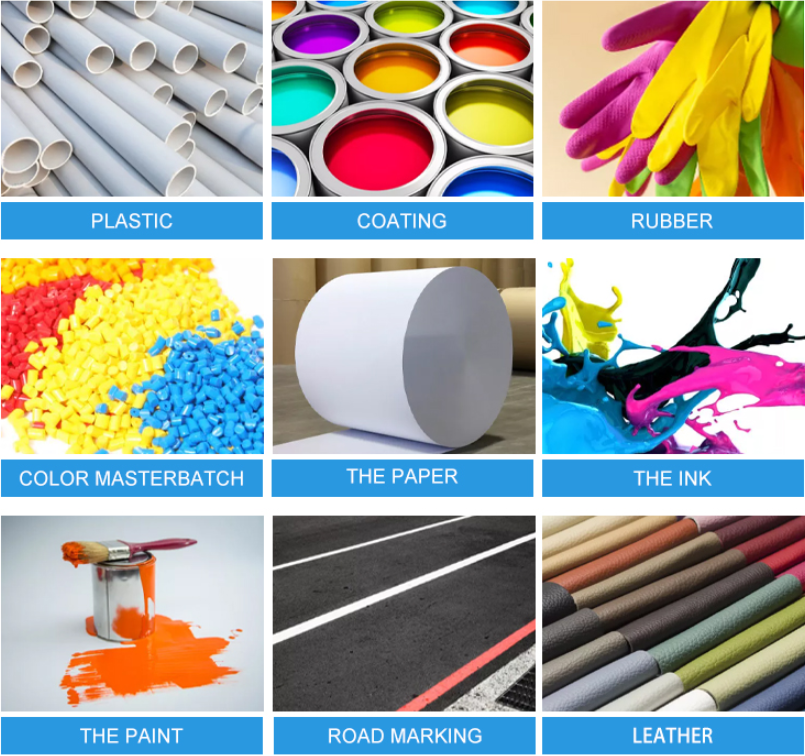

Titanium dioxide (TiO2), a white, opaque pigment, is extensively utilized across various industries due to its excellent opacity, brightness, and durability. With the CAS number 13463-67-7, TiO2 plays a significant role in products ranging from paints, coatings, and plastics to food and cosmetics. This article explores the landscape of suppliers for titanium dioxide, focusing on their importance, market dynamics, and considerations for buyers.

An Overview of Titanium Dioxide (CAS 13463-67-7) Suppliers

When searching for titanium dioxide suppliers, it is crucial to evaluate their production methods and the quality of the products. TiO2 can be produced through two primary processes the sulfate process and the chloride process. The sulfate process is generally more environmentally taxing, while the chloride process is recognized for producing higher purity and whiter grades of titanium dioxide. Suppliers that employ the chloride process often cater to high-end markets requiring superior performance characteristics.

dioxide titanium cas 13463-67-7 suppliers

Furthermore, the choice of supplier is influenced by geographic location and logistical considerations. Regions with abundant titanium ore resources, such as Australia, South Africa, and China, host several leading manufacturers. For businesses looking to procure TiO2, establishing a partnership with local suppliers can minimize shipping costs and ensure timely delivery.

In addition to evaluating product quality and logistics, sustainability practices and regulatory compliance are becoming increasingly important for buyers. Leading suppliers are now adopting eco-friendly practices, such as reducing waste and energy consumption, to meet the growing demand for sustainable products. This commitment not only aligns with global environmental standards but also appeals to consumers who are more conscious of sustainability today.

In conclusion, the market for titanium dioxide suppliers is robust and continually evolving. Companies seeking to procure TiO2 need to consider factors such as production methods, product quality, supplier location, and sustainability practices. By doing so, they can ensure that they partner with suppliers who not only meet their technical requirements but also align with their corporate values and goals. As the industry grows, staying informed about supplier capabilities and market trends will be crucial for organizations aiming to maintain a competitive advantage in their respective fields.

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025