Dec . 11, 2024 05:09 Back to list

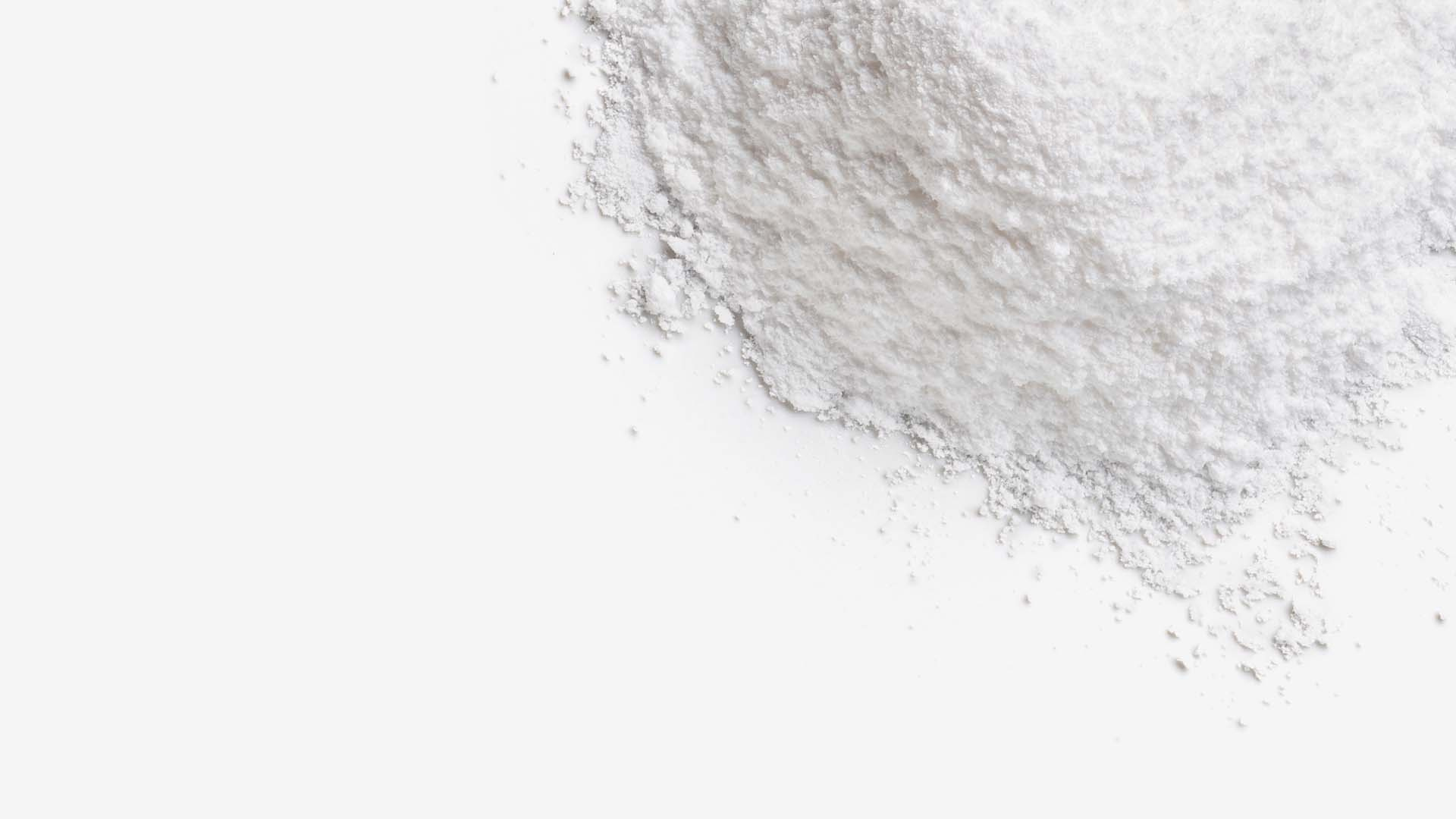

High Purity Titanium Dioxide 99% Manufacturer for Industrial Applications and Premium Products

Understanding the Importance of 99% Titanium Dioxide Manufacturers

Titanium dioxide (TiO2) is a naturally occurring oxide of titanium that has become a vital substance in various industries due to its exceptional properties. With an impressive purity of 99%, titanium dioxide is sought after for applications that require high-performance materials. This article explores the significance of 99% titanium dioxide manufacturers, their processes, the industries they serve, and the future of this essential compound.

The Fundamentals of Titanium Dioxide

Titanium dioxide is a white pigment widely used in paints, coatings, plastics, and paper. Its properties, including high refractive index, UV resistance, and non-toxicity, make it an ideal choice for these applications. The two primary processes for producing titanium dioxide are the sulfate process and the chloride process. The sulfate process involves the acidulation of titanium ores, while the chloride process uses titanium tetrachloride, yielding a product of higher purity and finer particle size, which often results in enhanced performance in applications.

Why 99% Purity Matters

The significance of 99% purity in titanium dioxide cannot be overstated. The presence of impurities can adversely affect its color and opacity, making it unsuitable for applications where these properties are critical. High-purity titanium dioxide is essential in industries that demand precise color matching and optimal performance, such as automotive, cosmetics, and food packaging.

For instance, the automotive industry relies on high-quality pigments for finishes that not only require vibrant colors but also need to withstand environmental degradation. In cosmetics, the use of 99% titanium dioxide as a physical UV filter is critical for providing sun protection without causing skin irritation. Similarly, food packaging must ensure that materials are safe and non-leachable, making the purity of titanium dioxide a crucial factor.

The Role of 99% Titanium Dioxide Manufacturers

Manufacturers specializing in 99% titanium dioxide have the responsibility of ensuring that their production processes adhere to strict quality controls and industry standards. These manufacturers invest in advanced technology and methodologies to produce high-grade titanium dioxide, often employing sophisticated characterization techniques to analyze and guarantee product purity.

dioxide titanium 99% manufacturer

Collaboration with suppliers of raw materials is also vital. Sourcing high-quality titanium ores and maintaining stringent control throughout the production process enable manufacturers to provide a product that meets the expectations of their clients. Moreover, a commitment to sustainability and environmental responsibility has become increasingly important in the manufacturing process. Companies are exploring ways to minimize their ecological footprint while delivering superior products.

Industry Applications

The versatility of 99% titanium dioxide means that it finds applications across a vast array of sectors. In construction, it serves as a pigment in paints and coatings that offer durability and aesthetic appeal. In the plastics industry, it enhances the opacity and brightness of products, ensuring visual appeal. Furthermore, the rise of eco-friendly and sustainable products has increased demand for non-toxic and reliable materials like high-purity titanium dioxide.

With the cosmetics industry continuing to grow, the need for safe, high-performance ingredients is more crucial than ever. The global push for cleaner and safer products has led manufacturers to innovate and improve their formulations, making 99% titanium dioxide a favored choice.

The Future of Titanium Dioxide

The market for titanium dioxide is expected to grow, driven by increasing demand in various sectors and technological advancements. The evolution of consumer preferences towards sustainable and high-quality products presents an excellent opportunity for manufacturers. Innovation in production techniques, such as the development of more efficient methods or alternative raw materials, could redefine industry standards.

Additionally, as regulations around environmental impacts tighten, manufacturers focusing on sustainability will likely gain a competitive edge. Companies that prioritize eco-friendly production practices and transparency in their sourcing can appeal to an increasingly conscious consumer base.

Conclusion

99% titanium dioxide manufacturers play an integral role in providing high-quality materials that boost the performance of numerous products we use daily. As industries continue to adapt to changing regulations and consumer preferences, the demand for high-purity titanium dioxide will only grow. Through innovation, sustainability, and adherence to stringent quality standards, these manufacturers will remain at the forefront of the materials sector, paving the way for new applications and advancements in technology.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025