Dec . 05, 2024 15:37 Back to list

color of baso4 factories

The Significance of Color in Barium Sulfate (BaSO4) Factories

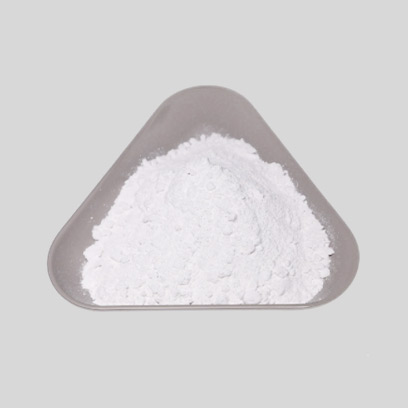

Barium sulfate (BaSO4) is a white, crystalline material extensively used in a multitude of industries, ranging from pharmaceuticals to plastics and paints. While its composition is critical to its application, the color of barium sulfate produced in factories can also carry significant implications, both from an aesthetic and a functional standpoint.

The production of barium sulfate typically employs various processes, including the precipitation method, where barium ions react with sulfate ions to form the compound. The control of the manufacturing environment, including factors like temperature and pH, can influence the final product’s characteristics, including color. While the standard form of barium sulfate is pure white, variations in color can occur due to impurities, additives, or the processing techniques used. This variations in color can impact the marketability of the product, as some industries have specific color requirements for their applications.

The Significance of Color in Barium Sulfate (BaSO4) Factories

In the plastics industry, the color of barium sulfate plays a similar role. It is commonly employed as a filler to improve the mechanical strength and brightness of plastic products. Colored barium sulfate can be essential where specific aesthetic qualities are desired in consumer products. Packaging materials, toys, and household items often benefit from the customized coloration of barium sulfate, making it a versatile additive. Furthermore, the ability to produce differently colored grades of barium sulfate enables manufacturers to tailor their products to meet the growing demand for eco-friendly and visually appealing materials.

color of baso4 factories

In the pharmaceutical sector, the use of barium sulfate extends to medical imaging, notably in barium meals or enemas, which are utilized for X-ray imaging of the gastrointestinal tract. Here, the emphasis is primarily on the purity and safety of the product rather than its color. Nevertheless, the presentation can still play a role, as the patient experience is enhanced by visually appealing and properly packaged products. Manufacturers must ensure that the color of any product marketed for medical purposes adheres to strict regulatory standards, maintaining the integrity and safety of the final product.

The production processes in BaSO4 factories are also designed with environmental impact in mind. Advances in technology have enabled the development of eco-friendly production methods that minimize waste and optimize resources. This includes not only the physical production of barium sulfate but also the management of coloration processes. Utilizing natural or non-toxic colorants can further reduce the factories' environmental footprint and appeal to the growing base of environmentally conscious consumers.

Moreover, the strategic choice of colors in barium sulfate factories can influence branding and marketing efforts. A factory that can produce a unique or proprietary shade of barium sulfate may find itself in a stronger competitive position. As industries increasingly seek differentiated products to stand out in the marketplace, the ability to customize color and ensure product consistency becomes an essential trait.

In conclusion, while the chemical properties of barium sulfate are vital to its function across varied industries, the color produced in manufacturing plays a multifaceted role in enhancing product appeal, compliance with regulatory standards, and supporting branding efforts. As BaSO4 factories continue to evolve, the integration of advanced production technologies and color customization will serve to meet both aesthetic and practical demands, ensuring that barium sulfate remains a critical component across diverse applications.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025