colloidal silicon dioxide manufacturers

Feb . 15, 2025 11:40 Back to list

colloidal silicon dioxide manufacturers

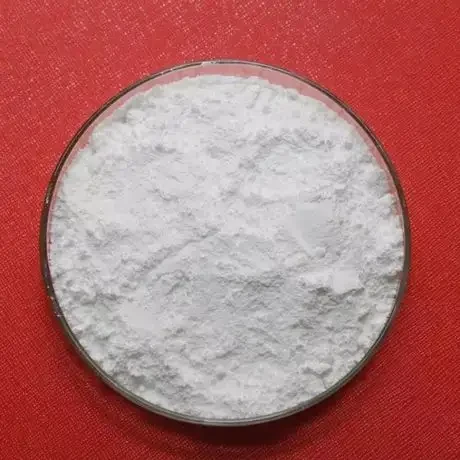

In the highly specialized world of industrial and pharmaceutical applications, colloidal silicon dioxide plays a pivotal role. This versatile compound, known for its properties as an anti-caking agent, stabilizer, and excipient, is indispensable in a variety of sectors, including food production, pharmaceuticals, and cosmetics. Here, we delve into the realm of colloidal silicon dioxide manufacturers, shedding light on the intricacies of production, quality assurance, and the key factors that set industry leaders apart.

Authoritativeness in the market is often reflected by an extensive portfolio of partnerships and collaborations with renowned academic and research institutions. These alliances are pivotal in fostering an environment of innovation and knowledge exchange, allowing manufacturers to stay at the forefront of technological advancements. Moreover, consistent publication of research findings in peer-reviewed journals and presentations at industry conferences further solidifies a manufacturer's position as an authority in the field. Trustworthiness, particularly in a sector that heavily influences consumer safety, is a non-negotiable attribute. Manufacturers with a strong commitment to transparency and ethical sourcing of raw materials are favored by discerning clients. Third-party audits and certifications from regulatory bodies such as the Food and Drug Administration (FDA) in the USA or the European Medicines Agency (EMA) provide added assurance of a manufacturer's credibility and adherence to regulatory mandates. The product range offered by a manufacturer is also a testament to their expertise and adaptability. From high-purity grade colloidal silicon dioxide used in pharmaceutical applications to food-grade varieties for the food and beverage industry, the ability to customize products to meet specific client requirements is a hallmark of a top-tier manufacturer. This customization process not only involves technical modifications but also includes tailored packaging solutions to enhance shelf life and usability. In conclusion, the landscape of colloidal silicon dioxide manufacturing is characterized by a blend of experience, expertise, authoritativeness, and trustworthiness. As the demand for high-quality colloidal silicon dioxide continues to grow across diverse industries, manufacturers that uphold these tenets are well-positioned to lead the market. By focusing on rigorous quality control, embracing innovation through R&D, maintaining authoritative industry presence, and ensuring trustworthy relationships with all stakeholders, these manufacturers not only meet but exceed the expectations of their global clientele.

Authoritativeness in the market is often reflected by an extensive portfolio of partnerships and collaborations with renowned academic and research institutions. These alliances are pivotal in fostering an environment of innovation and knowledge exchange, allowing manufacturers to stay at the forefront of technological advancements. Moreover, consistent publication of research findings in peer-reviewed journals and presentations at industry conferences further solidifies a manufacturer's position as an authority in the field. Trustworthiness, particularly in a sector that heavily influences consumer safety, is a non-negotiable attribute. Manufacturers with a strong commitment to transparency and ethical sourcing of raw materials are favored by discerning clients. Third-party audits and certifications from regulatory bodies such as the Food and Drug Administration (FDA) in the USA or the European Medicines Agency (EMA) provide added assurance of a manufacturer's credibility and adherence to regulatory mandates. The product range offered by a manufacturer is also a testament to their expertise and adaptability. From high-purity grade colloidal silicon dioxide used in pharmaceutical applications to food-grade varieties for the food and beverage industry, the ability to customize products to meet specific client requirements is a hallmark of a top-tier manufacturer. This customization process not only involves technical modifications but also includes tailored packaging solutions to enhance shelf life and usability. In conclusion, the landscape of colloidal silicon dioxide manufacturing is characterized by a blend of experience, expertise, authoritativeness, and trustworthiness. As the demand for high-quality colloidal silicon dioxide continues to grow across diverse industries, manufacturers that uphold these tenets are well-positioned to lead the market. By focusing on rigorous quality control, embracing innovation through R&D, maintaining authoritative industry presence, and ensuring trustworthy relationships with all stakeholders, these manufacturers not only meet but exceed the expectations of their global clientele.

Latest news

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025