Titanium dioxide for soap, detergent and toiletry products

Mar . 06, 2025 16:54 Back to list

Titanium dioxide for soap, detergent and toiletry products

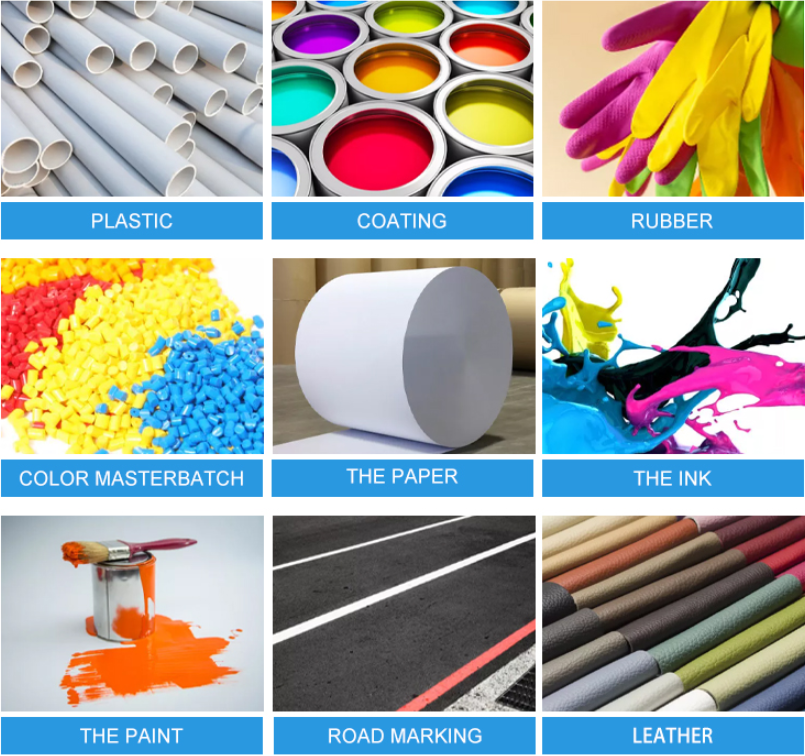

In the bustling world of advanced technology, the incorporation of nano titania in coating production factories has become a game-changer. As industries push the boundaries of innovation, the utilization of nano-sized titanium dioxide (TiO2) showcases significant advancements in coating applications. Nano titania, renowned for its remarkable properties, has elevated the standards of durability, functionality, and environmental sustainability within products.

Factories specializing in these coatings are continuously innovating to overcome challenges such as agglomeration of nanoparticles, which can affect coating uniformity. Through research and development, experts in the field are devising new methods to stabilize nanoparticles within the coating matrix. This ensures that the unique properties of nano titania are harnessed to their full extent, offering robust and reliable products that meet the rigorous standards demanded by industries today. From an authoritative standpoint, regulations surrounding the use of nano titania are strictly monitored to ensure consumer safety and environmental compliance. Trusted manufacturers adhere to industry standards and certifications, providing assurance of their coatings’ efficacy and safety. By meeting these rigorous guidelines, factories affirm their commitment to delivering high-quality, reliable products trusted by consumers worldwide. In terms of trustworthiness, these coatings have been subjected to extensive testing and validation, with results substantiating their performance under various conditions. Studies confirm that nano titania coatings are not only effective in providing protection against environmental factors but also in prolonging the life and appearance of diverse substrates. This bolsters consumer confidence, driving the adoption of such innovative solutions across multiple sectors. Ultimately, the use of nano titania in coating production represents a remarkable fusion of technology and practicality. It exemplifies how advancements in material science can be leveraged to produce superior products that cater to the evolving demands of modern industries. As research continues to unveil new potential applications, the role of nano titania coatings in promoting sustainability and innovation is set to expand, opening new frontiers in industrial advancements and environmental stewardship.

Factories specializing in these coatings are continuously innovating to overcome challenges such as agglomeration of nanoparticles, which can affect coating uniformity. Through research and development, experts in the field are devising new methods to stabilize nanoparticles within the coating matrix. This ensures that the unique properties of nano titania are harnessed to their full extent, offering robust and reliable products that meet the rigorous standards demanded by industries today. From an authoritative standpoint, regulations surrounding the use of nano titania are strictly monitored to ensure consumer safety and environmental compliance. Trusted manufacturers adhere to industry standards and certifications, providing assurance of their coatings’ efficacy and safety. By meeting these rigorous guidelines, factories affirm their commitment to delivering high-quality, reliable products trusted by consumers worldwide. In terms of trustworthiness, these coatings have been subjected to extensive testing and validation, with results substantiating their performance under various conditions. Studies confirm that nano titania coatings are not only effective in providing protection against environmental factors but also in prolonging the life and appearance of diverse substrates. This bolsters consumer confidence, driving the adoption of such innovative solutions across multiple sectors. Ultimately, the use of nano titania in coating production represents a remarkable fusion of technology and practicality. It exemplifies how advancements in material science can be leveraged to produce superior products that cater to the evolving demands of modern industries. As research continues to unveil new potential applications, the role of nano titania coatings in promoting sustainability and innovation is set to expand, opening new frontiers in industrial advancements and environmental stewardship.

Latest news

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025