Dec . 12, 2024 17:17 Back to list

coating material tio2 supplier

The Role of TiO2 as a Coating Material Suppliers and Innovations

Titanium dioxide (TiO2) is one of the most important materials used in a wide range of applications, particularly as a pigment and coating. Its unique properties, including excellent opacity, brightness, and UV resistance, make it a highly sought-after choice for various industries, such as paints, coatings, cosmetics, and plastics. As the demand for high-quality TiO2 continues to rise, understanding the role of reliable suppliers in the production and distribution of this material becomes crucial.

What is TiO2?

Titanium dioxide is an inorganic compound with the formula TiO2. It naturally occurs in various minerals, such as ilmenite, rutile, and anatase. TiO2 is primarily known for its use as a white pigment due to its high refractive index and strong UV light absorbing capacity. However, it also possesses photocatalytic properties, which make it useful in self-cleaning surfaces and air purification applications. Furthermore, TiO2 is non-toxic, making it suitable for use in consumer products, including food additives and cosmetics.

The Importance of TiO2 in Coatings

In the coatings industry, TiO2 is essential for providing durability, corrosion resistance, and aesthetic appeal. Its ability to scatter light helps enhance the brightness and whiteness of coatings, ensuring vibrant and long-lasting finishes. TiO2-based coatings are used in industrial applications, automotive finishes, and architectural coatings, where both performance and aesthetics are critical.

Additionally, TiO2 plays a significant role in improving the photocatalytic properties of coatings, enabling them to break down organic pollutants and harmful substances when exposed to light. This feature is increasingly being utilized in environmental applications, promoting sustainable practices by reducing air and water pollution.

Key Suppliers of TiO2

As the demand for TiO2 continues to grow, several major suppliers have emerged as leaders in the industry. These suppliers not only provide high-quality TiO2 but also invest in research and development to enhance the performance and applications of their products.

coating material tio2 supplier

1. Chemours Company A prominent name in the chemical industry, Chemours is known for its TiO2 brand, Ti-Pure. The company focuses on offering bright whiteness, strong opacity, and excellent outdoor durability, making it a preferred choice for manufacturers looking for quality coatings.

2. Tronox Holdings PLC Tronox is one of the world's largest producers of TiO2, and its products are used extensively in coatings, plastics, and other applications. With a commitment to sustainability, Tronox continuously explores ways to improve its manufacturing processes and reduce environmental impact.

3. Huntsman Corporation With a rich portfolio of specialty chemicals, Huntsman provides premium-grade TiO2 that satisfies the rigorous requirements of the coatings market. Their innovative approach includes developing new formulations that enhance the performance and functionality of TiO2 in coatings.

4. Kronshtadt Known for its high-purity TiO2, Kronshtadt caters to niche markets seeking specialized applications. Their focus on tailored solutions positions them as a valuable supplier for customers requiring specific properties in their coatings.

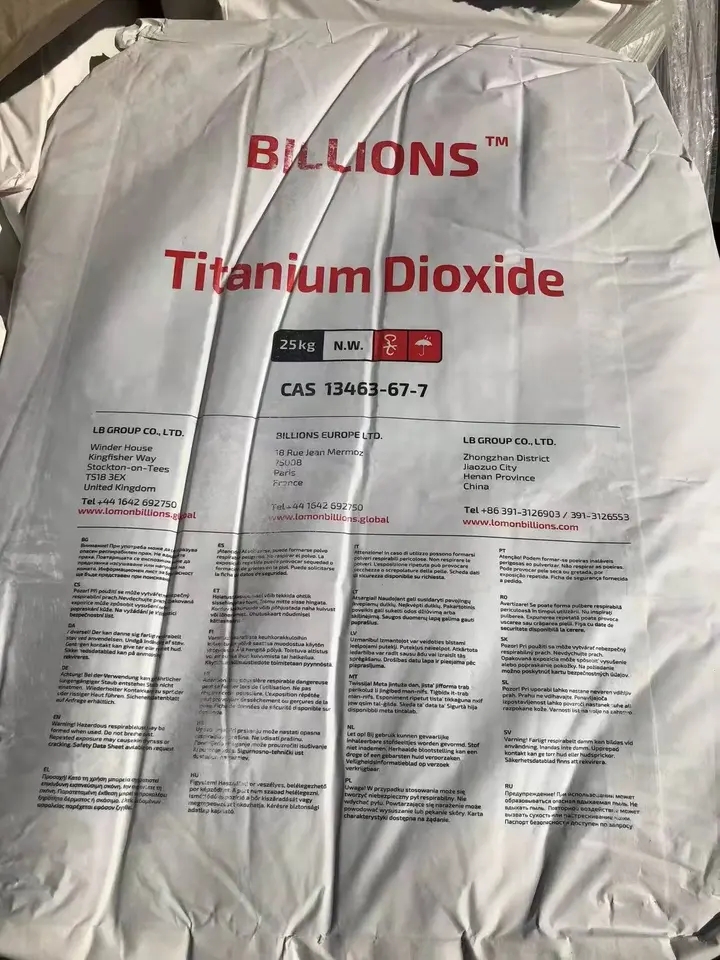

5. Lomon Billions Group Based in China, Lomon Billions is one of Asia's leading producers of TiO2. With an emphasis on innovation and quality, the company exports its products globally and has garnered a reputation for meeting the diverse needs of its customers.

Innovations and Future Directions

The coatings market is evolving, with new technologies and applications emerging constantly. One of the significant trends is the development of eco-friendly formulations that minimize the environmental impact of TiO2 production and its end-use. Suppliers are actively working on optimizing the manufacturing processes and exploring alternative materials to create more sustainable products.

Moreover, as industries move toward digital solutions, the integration of smart coatings equipped with TiO2 is gaining traction. These coatings can respond to environmental changes, providing enhanced functionality such as self-healing properties and improved durability.

In conclusion, TiO2 remains a critical component in the coatings industry, driven by its superior characteristics and versatility. As suppliers continue to innovate and adapt to market demands, the future of TiO2 in coatings looks promising, paving the way for enhanced performance and sustainability in various applications. The journey of finding the right TiO2 supplier is essential for manufacturers aiming to deliver high-quality products and stay competitive in the ever-evolving marketplace.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025