Dec . 01, 2024 11:39 Back to list

High-Quality Coated Titanium Dioxide Suppliers for Various Industrial Applications

The Role of Coated Titanium Dioxide Manufacturers in Modern Industries

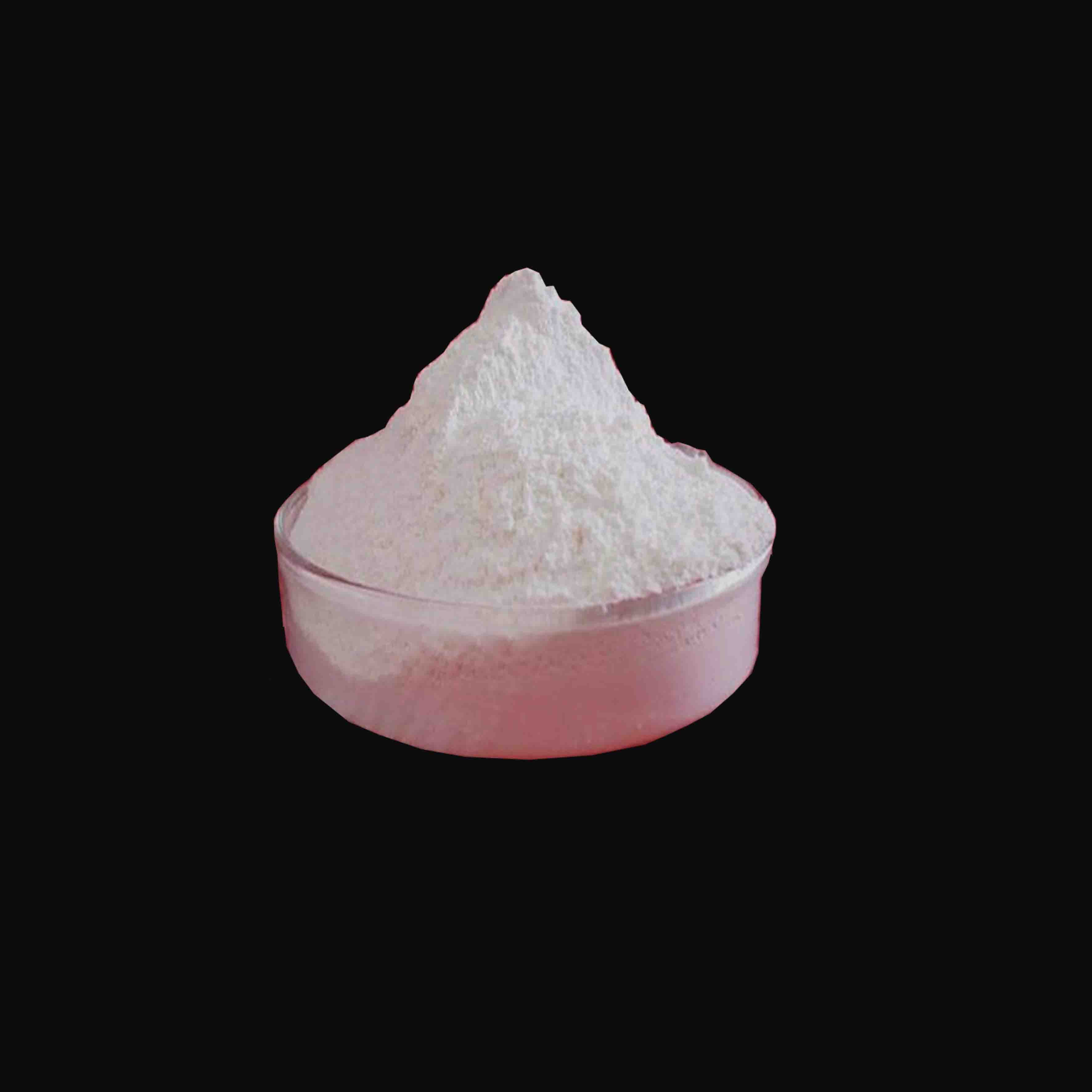

In the realm of advanced materials, coated titanium dioxide (TiO2) has emerged as a pivotal compound, utilized across numerous industries for its unique properties. From enhancing the aesthetic quality of paints to acting as an effective photocatalyst in environmental applications, the demand for coated titanium dioxide is steadily increasing. As such, manufacturers specializing in this vital compound are playing a crucial role in meeting the diverse needs of various sectors, including construction, cosmetics, and electronics.

Understanding Coated Titanium Dioxide

Titanium dioxide, known for its high refractive index, bright whiteness, and superior UV resistance, has long been a staple in the production of paints, coatings, and plastics. However, the raw form of TiO2 can sometimes fall short in terms of dispersibility and stability in formulations. This is where coating technologies come into play. Manufacturers utilize different coating techniques, such as silica, alumina, or organic layers, to enhance TiO2's performance, improving its compatibility with a wider range of materials and applications.

Coated TiO2 particles exhibit improved dispersion in liquids, enhanced durability, and greater resistance to chalking and weathering compared to their uncoated counterparts. This makes them ideal for high-performance applications in various industries, including paints and coatings, photocatalysis, and even food products where safety is paramount.

Applications Across Industries

1. Paints and Coatings One of the primary applications of coated titanium dioxide is in the paint and coatings industry. Coated TiO2 is crucial for formulating high-quality paints that require long-lasting durability and brightness. The coatings provide improved UV protection and reduce the degradation of the paint film over time, ensuring that surfaces retain their aesthetic appeal.

2. Cosmetics In the cosmetics industry, coated titanium dioxide is favored for its ability to provide coverage, sun protection, and a smooth finish in products such as foundations, sunscreens, and powders. The nanoparticles enhance SPF levels without leaving a white residue on the skin, making them a preferred choice for consumers looking for effective sun protection.

coated titanium dioxide manufacturer

3. Photocatalysis The photocatalytic properties of titanium dioxide have garnered significant attention in environmental applications. Coated TiO2 is used in water treatment systems, self-cleaning surfaces, and air purification technologies. Manufacturers are continuously innovating to optimize the photocatalytic efficiency of TiO2, contributing to cleaner water and air solutions.

4. Plastics and Polymers In the plastics industry, coated titanium dioxide is utilized to improve the color stability and UV resistance of products. This ensures that plastic items maintain their visual appeal and structural integrity when exposed to harsh environmental conditions.

Choosing the Right Manufacturer

When selecting a coated titanium dioxide manufacturer, several factors must be considered. Quality control is paramount; reputable manufacturers adhere to stringent regulations and standards to ensure that their products are both effective and safe. Additionally, the ability to customize formulations to meet specific client requirements can set a manufacturer apart in a competitive landscape.

Furthermore, sustainability practices are increasingly important, as industries strive to minimize their environmental footprint. Manufacturers that prioritize eco-friendly production processes and sourcing of raw materials are becoming increasingly preferred by conscientious consumers and businesses alike.

Conclusion

Coated titanium dioxide is a multifaceted material that plays an instrumental role in various industries. From enriching the quality of paints and cosmetics to contributing to environmental sustainability through photocatalysis, the importance of specialized manufacturers cannot be overstated. As demand continues to grow, innovation and quality will remain key drivers in the evolution of coated titanium dioxide, ensuring its vital role in future advancements across diverse applications.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025