Nov . 06, 2024 11:06 Back to list

Chlorination Techniques for Titanium Dioxide Production in Modern Manufacturing Facilities

The Chlorination Process in Titanium Dioxide Production

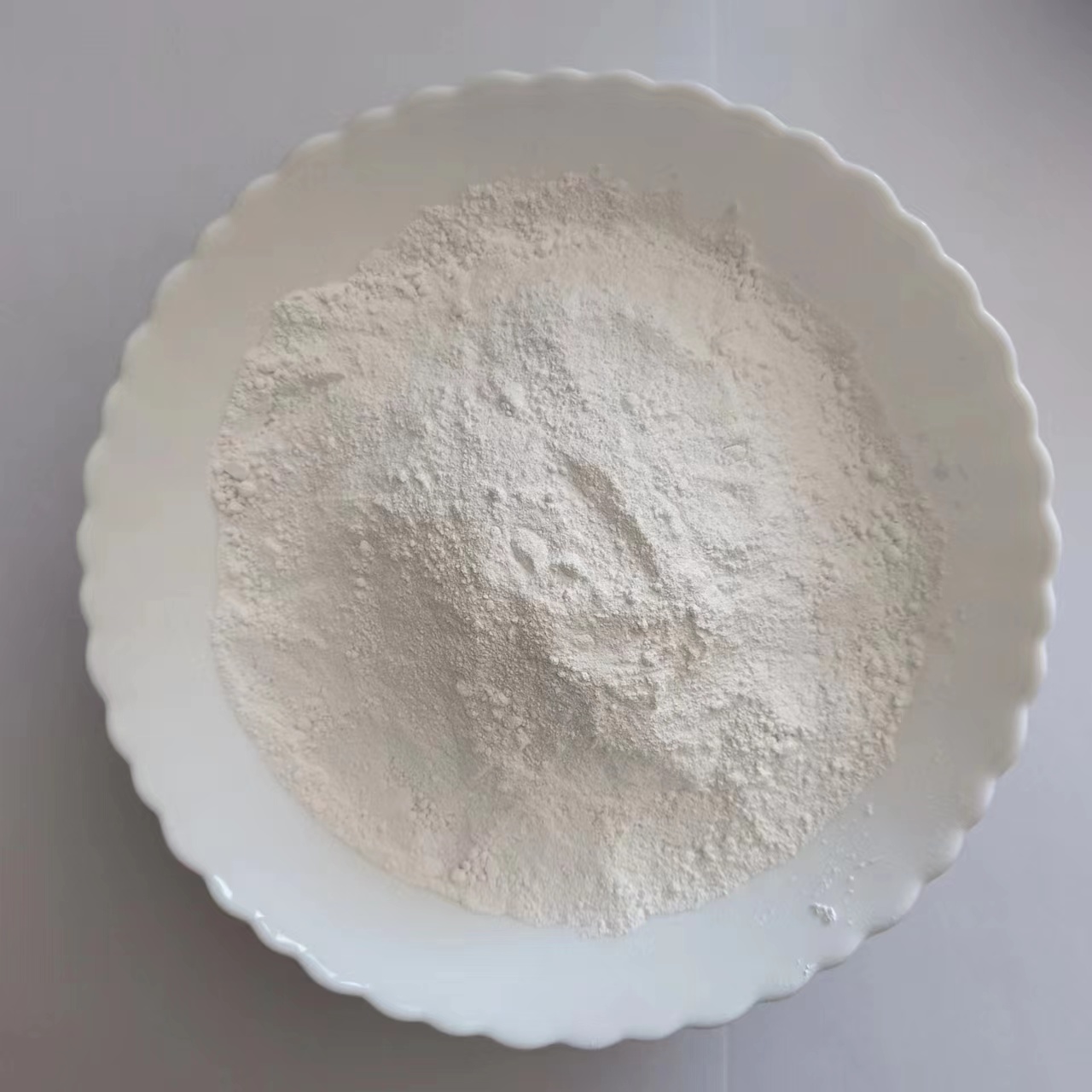

Titanium dioxide (TiO2) is one of the most widely used white pigments in the world, renowned for its vibrant whiteness and excellent opacity. Its applications span across various industries, including paints, coatings, plastics, and cosmetics. The production of titanium dioxide typically occurs through two primary processes the sulfate process and the chloride process. Among these, the chloride process is gaining increasing favor due to its efficiency and lower environmental impact.

At its core, the chloride process involves the conversion of titanium-containing ores, such as ilmenite or rutile, into titanium tetrachloride (TiCl4) through a chlorination reaction. This chemical transformation is pivotal, as TiCl4 serves as the key intermediate for producing high-purity titanium dioxide. The following discusses the intricacies of the chlorination process and its importance in the titanium dioxide manufacturing sector.

Raw Material Preparation

The process begins with the selection and preparation of the titanium ores. Rutile, with its high titanium content, and ilmenite, which contains iron impurities, are commonly used. The ores undergo a series of pre-treatments, including crushing, grinding, and heating, typically in the presence of carbon. The heating process encourages the formation of a more reactive structure, paving the way for efficient chlorination.

Chlorination Reaction

Once the titanium ores are suitably prepared, they are introduced into a chlorination reactor. The circulating fluidized bed (CFB) reactor is frequently employed in the chlorination process owing to its enhanced contact between the solid particles and gaseous chlorine (Cl2). The typical reaction can be summarized as

\[ \text{TiO}_2 + 2\text{Cl}_2 + \text{C} \rightarrow \text{TiCl}_4 + \text{CO}_2 \]

During this reaction, the titanium dioxide from the ore reacts with chlorine gas in the presence of carbon, resulting in titanium tetrachloride and carbon dioxide. The reaction temperature is typically maintained between 900 and 1,100 degrees Celsius. The use of a fluidized bed allows for optimal heat transfer and reaction kinetics, enhancing the overall efficiency of the process.

Separation and Purification

chlorination process titanium dioxide factory

The gaseous TiCl4 produced is then cooled and condensed into a liquid, separating it from impurities such as unreacted chlorine and carbon. To further purify the titanium tetrachloride, distillation techniques are employed, allowing for the removal of trace elements and impurities that could affect the quality of the final titanium dioxide product.

Conversion to Titanium Dioxide

The purified TiCl4 is subsequently subjected to oxidation to produce titanium dioxide. This is achieved by reacting the TiCl4 with oxygen in a high-temperature furnace, typically at temperatures around 1,500 degrees Celsius

\[ \text{TiCl}_4 + 2\text{O}_2 \rightarrow \text{TiO}_2 + 4\text{Cl}_2 \]

The result is high-purity titanium dioxide, which can then be processed for various applications. The TiO2 produced via the chloride process is known for its superior brightness, higher purity, and better performance characteristics compared to that produced via the sulfate process.

Environmental Impact and Considerations

The chloride process is not only more efficient but also presents a lower environmental footprint. It generates fewer waste products compared to the sulfate process, which produces significant amounts of sulfuric acid as waste. Furthermore, advancements in technology have led to more effective recycling of chlorine, reducing the overall consumption of raw materials.

Conclusion

The chlorination process in titanium dioxide production stands as a testament to advancements in chemical engineering and materials science. With its ability to produce high-purity TiO2 in a more environmentally friendly manner, the chloride process continues to play a crucial role in meeting the demands of various industries while promoting sustainable practices. As technology evolves, further improvements and innovations in this process are anticipated, ensuring that the titanium dioxide sector remains dynamic and responsive to the needs of its markets.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025