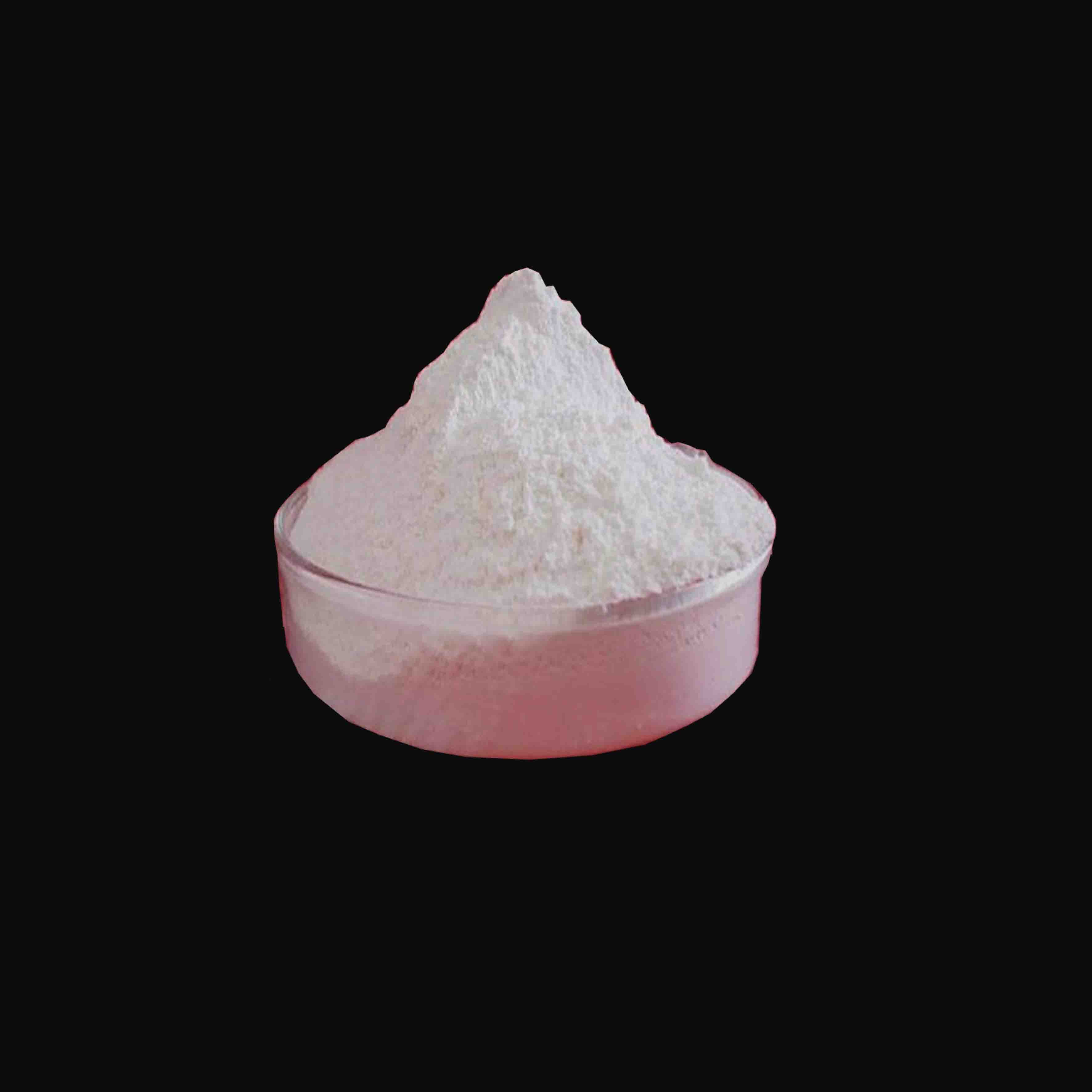

china titanium dioxide r605 powder coating multi-purpose product titanium dioxide pigment

Jan . 14, 2025 12:42 Back to list

china titanium dioxide r605 powder coating multi-purpose product titanium dioxide pigment

Titanium dioxide (TiO2) has revolutionized the coatings industry with its exceptional properties that enhance the durability, appearance, and functionality of the coated surfaces. As an experienced professional in surface science, I can attest that the integration of titanium dioxide in coatings is not just a trend; it's a robust solution supported by decades of research and practical application.

From an expert's perspective, the versatility of titanium dioxide isn't limited to its chemical properties. TiO2 coatings can be tailored to meet specific needs by manipulating factors such as particle size, surface treatment, and formulation. This customization makes it possible to develop specialized coatings for unique industrial applications, ensuring that clients receive solutions optimized for their operational contexts. Despite the myriad benefits, employing TiO2 coatings requires careful consideration of formulation and application techniques to maximize performance. It is imperative to engage with experienced formulation chemists who understand the subtleties of dispersion and stability in order to prevent issues like flocculation, which can compromise the efficacy of the coating. Trustworthy suppliers who provide high-purity TiO2 and technical support can significantly enhance project outcomes. In conclusion, coatings utilizing titanium dioxide are an exemplary demonstration of combining scientific innovation with practical application. Their ability to improve productivity, enhance product life cycles, and contribute to safer, cleaner environments underscores their value across various sectors. Continuous research and development are set to unlock even more potential uses for titanium dioxide in the coatings industry, ensuring that it remains a staple for quality and performance in the years to come.

From an expert's perspective, the versatility of titanium dioxide isn't limited to its chemical properties. TiO2 coatings can be tailored to meet specific needs by manipulating factors such as particle size, surface treatment, and formulation. This customization makes it possible to develop specialized coatings for unique industrial applications, ensuring that clients receive solutions optimized for their operational contexts. Despite the myriad benefits, employing TiO2 coatings requires careful consideration of formulation and application techniques to maximize performance. It is imperative to engage with experienced formulation chemists who understand the subtleties of dispersion and stability in order to prevent issues like flocculation, which can compromise the efficacy of the coating. Trustworthy suppliers who provide high-purity TiO2 and technical support can significantly enhance project outcomes. In conclusion, coatings utilizing titanium dioxide are an exemplary demonstration of combining scientific innovation with practical application. Their ability to improve productivity, enhance product life cycles, and contribute to safer, cleaner environments underscores their value across various sectors. Continuous research and development are set to unlock even more potential uses for titanium dioxide in the coatings industry, ensuring that it remains a staple for quality and performance in the years to come.

Latest news

-

What is Barium Sulfate Board? Uses, Benefits & Industry Insights

NewsNov.25,2025

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025