Dec . 07, 2024 12:05 Back to list

china titanium dioxide for coatings

The Role of China in Titanium Dioxide Production for Coatings

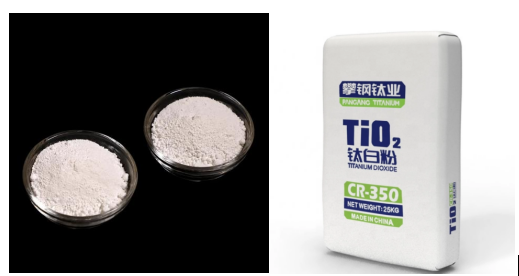

Titanium dioxide (TiO2) is a widely used white pigment and is essential in various applications, with coatings being one of the most significant sectors. Its unique properties, including high refractive index, excellent UV resistance, and durability, make it an ideal choice for enhancing the quality and longevity of coatings. With the global demand for titanium dioxide continuing to rise, China has emerged as a key player in its production and export.

China holds a dominant position in the global titanium dioxide market, accounting for a substantial share of the world's production capacity. This can be attributed to several factors, including abundant natural resources, a robust industrial infrastructure, and advanced manufacturing technologies. The country boasts rich deposits of titanium ores, primarily ilmenite, which serves as the primary raw material for titanium dioxide production. The availability of these raw materials has enabled Chinese manufacturers to establish cost-effective production processes and supply chains, giving them a competitive edge in the global market.

The Role of China in Titanium Dioxide Production for Coatings

During the past decade, China's titanium dioxide industry has made significant strides in environmental sustainability. Environmental regulations have tightened, pushing manufacturers to adopt cleaner technologies and reduce emissions during production. Many companies are investing in research and development to create eco-friendly alternatives in the production process, aiming to minimize their environmental impact while maintaining high production levels. This shift is not only beneficial for the environment but also aligns with the growing global trend towards sustainability and corporate responsibility.

china titanium dioxide for coatings

The coatings industry, a major consumer of titanium dioxide, has also witnessed a transformation in recent years. The demand for premium quality coatings has surged, driven by the construction, automotive, and consumer goods sectors. Coatings enriched with titanium dioxide offer exceptional durability, color retention, and ability to reflect UV light, making them particularly desirable in both exterior and interior applications. As a result, manufacturers in these sectors are increasingly relying on high-quality titanium dioxide produced in China.

Moreover, the global shift towards eco-friendly products and practices is influencing the intricacies of the coatings market. Waterborne and low-VOC (volatile organic compound) coatings require titanium dioxide that not only maintains performance but also complies with stringent environmental regulations. Chinese manufacturers are thus adapting their products to meet these evolving standards, emphasizing the importance of innovation in maintaining competitiveness.

As international trade dynamics evolve, China's titanium dioxide industry faces challenges and opportunities. Tariffs, trade restrictions, and geopolitical tensions can impact market accessibility. Nonetheless, China's commitment to improving production capabilities and enhancing product quality positions it well for future success. The exploration of new markets in developing countries also presents a significant opportunity for growth.

In conclusion, China's prominence in the titanium dioxide market for coatings is indicative of its strong industrial base and commitment to quality. As global demand continues to evolve, the country is well-poised to meet the needs of various sectors while embracing sustainability and innovation. The ongoing developments in manufacturing technologies and adherence to environmental standards will solidify China’s position as a leader in titanium dioxide production, benefiting industries worldwide that rely on this crucial pigment.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025