Dec . 19, 2024 10:23 Back to list

china titanium dioxide dissolved in oil

The Role of Titanium Dioxide in Oil-based Applications

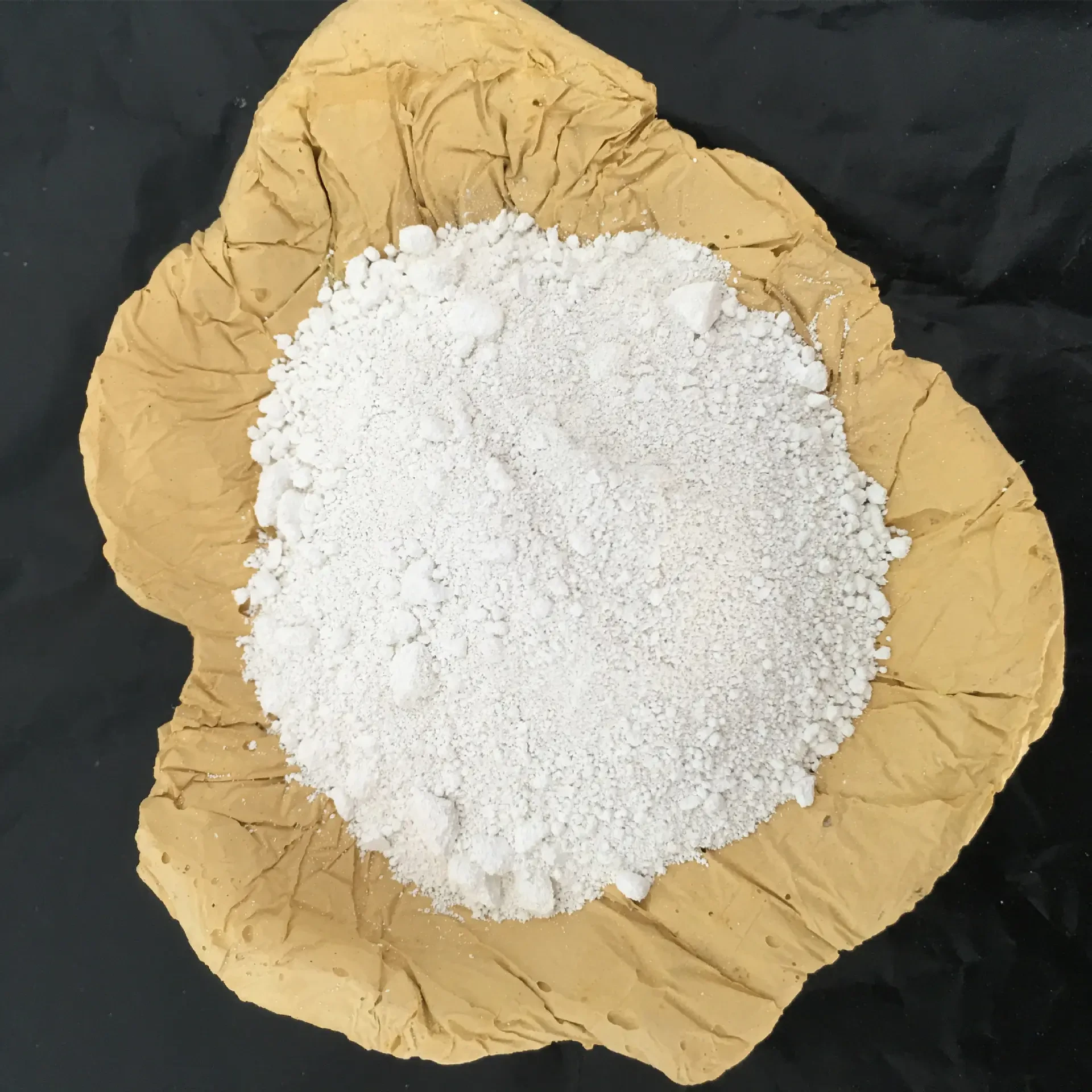

Titanium dioxide (TiO2) is a white, opaque pigment that plays a crucial role in various industries, including paints, coatings, plastics, and cosmetics. While it is primarily known for its exceptional brightness and opacity, recent innovations have seen the development of titanium dioxide that can dissolve in oil, opening up new avenues for its application in oil-based products.

Understanding Titanium Dioxide

Titanium dioxide is a naturally occurring mineral that has been extensively utilized due to its unique properties. It exists in several crystalline forms, with rutile and anatase being the most common. The compound is highly valued in the production of white pigments due to its strong light scattering capability and UV resistance. As a result, it is a staple ingredient in a wide range of products, from house paints to sunscreen.

The Dissolving Process

Traditional titanium dioxide is not soluble in oil, which limits its applications in oil-based systems. However, recent advancements in surface modification techniques have enabled the development of oil-dispersible forms of titanium dioxide. These modified particles can disperse in oil, making them advantageous for formulations requiring both opacity and flexibility in application.

The process begins with surface treatments, which involve altering the surface characteristics of titanium dioxide to enhance its compatibility with oils. This can include coating the particles with organic compounds that improve their affinity for oil or changing their surface charge. The resulting oil-dispersible titanium dioxide can then be integrated into various oil-based formulations, such as paints, adhesives, and inks.

Applications in Oil-based Products

china titanium dioxide dissolved in oil

1. Coatings and Paints Oil-based paints benefit significantly from the inclusion of titanium dioxide. By utilizing oil-dispersible TiO2, manufacturers can achieve superior opacity and a smooth finish. These paints, often used for exterior applications, can withstand harsh environmental conditions, including UV exposure and moisture.

2. Cosmetics The cosmetic industry has seen a growing interest in oil-dispersible titanium dioxide. In products such as foundations and sunscreens, it serves a dual purpose providing color and ensuring sun protection. Its ability to dissolve in oil means it can be incorporated into lightweight formulations, which are often more pleasing to consumers seeking natural-looking finishes.

3. Inks The printing industry has adopted oil-dispersible titanium dioxide for its ability to enhance the quality of inks. It improves opacity and color vibrancy, which is crucial for achieving eye-catching prints. This application is particularly valuable in the production of high-quality graphics and packaging materials.

4. Adhesives In the adhesive industry, the use of titanium dioxide can improve the mechanical properties and durability of products. Oil-dispersible TiO2 can aid in achieving a stronger bond while maintaining the necessary flexibility, making it advantageous for a variety of applications, including construction and automotive.

Environmental Considerations

While titanium dioxide is generally regarded as safe, concerns have been raised about potential health risks associated with its nanoparticle form, especially in inhalable products. This has led to increased regulatory scrutiny and calls for more sustainable practices in its production and application. The development of oil-dispersible versions of titanium dioxide should also consider these environmental implications, aiming for sustainable sourcing and responsible manufacturing processes.

Conclusion

The innovation of titanium dioxide that dissolves in oil represents a significant advancement in materials science, with the potential to transform various industries. Its versatile applications—from paints and cosmetics to inks and adhesives—highlight its importance as a multifunctional material. As researchers continue to explore and refine its capabilities, oil-dispersible titanium dioxide is poised to become an essential component in developing high-performance oil-based products, paving the way for greater creativity and sustainability in product formulation.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025