Dec . 13, 2024 16:22 Back to list

china rutile vs anatase

A Comparative Analysis of Rutile and Anatase The Dual Facets of Titanium Dioxide in China

Introduction

Titanium dioxide (TiO2) is one of the most widely used materials in various industries, ranging from pigments and paints to photovoltaic cells and cosmetics. It exists mainly in three crystalline forms rutile, anatase, and brookite, with rutile and anatase being the most commercially significant. In the context of China, which stands as a leading producer and consumer of titanium dioxide, understanding the comparative properties and applications of rutile and anatase is crucial.

Rutile The Dominant Form

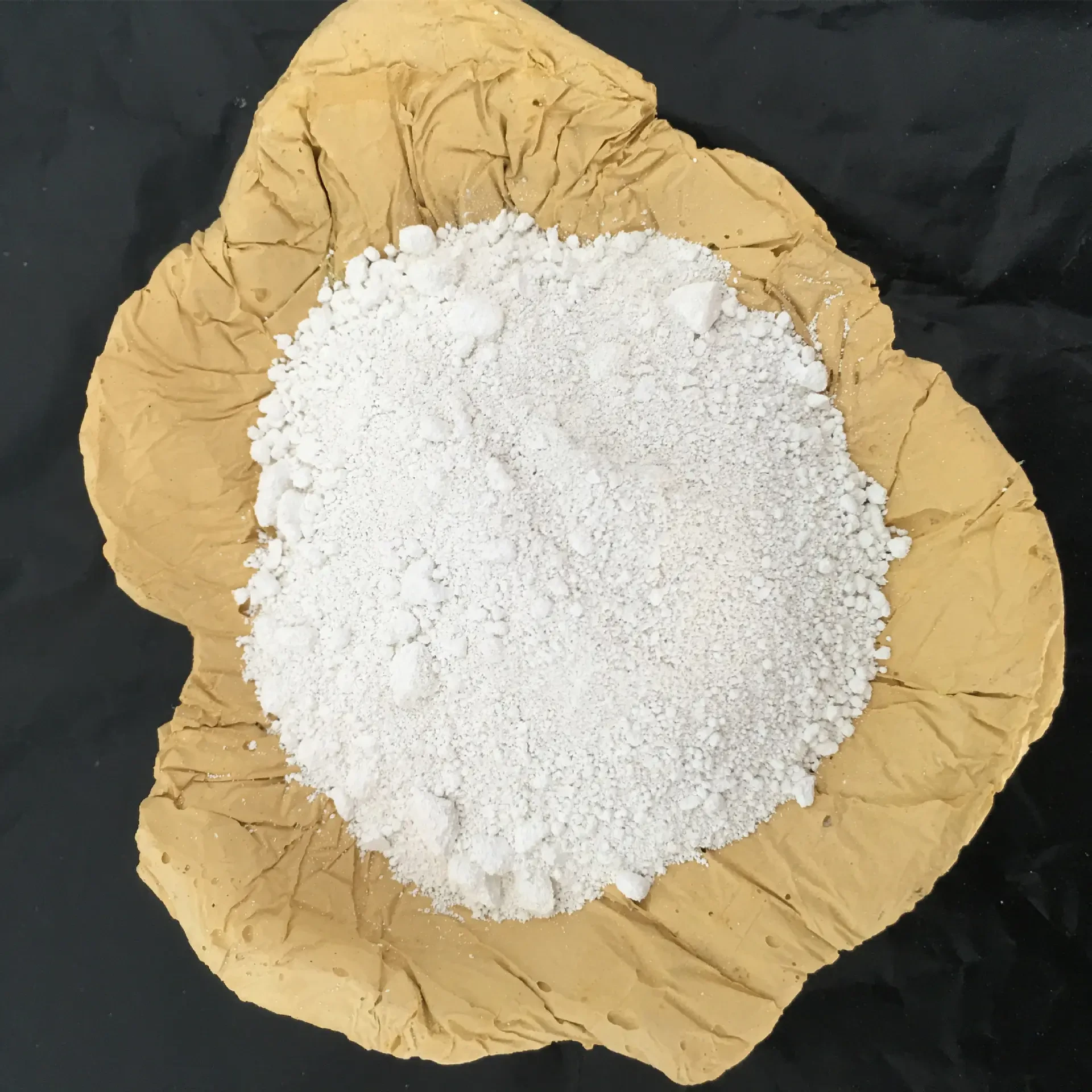

Rutile is the more thermodynamically stable and dense form of titanium dioxide. It typically possesses a tetragonal crystal structure and exhibits a high refractive index, which makes it an excellent white pigment. The high stability of rutile at elevated temperatures and its resistance to photocatalytic degradation make it preferred for outdoor applications, such as paints and coatings. Additionally, rutile-based pigments exhibit superior opacity, which enhances their performance in various applications.

In the Chinese market, the dominance of rutile TiO2 is significant due to its efficiency in providing UV protection and durability in harsh environments. The production of rutile primarily involves the sulfate and chloride processes, where the chloride method is gaining preference owing to its lower production costs and reduced environmental impact. Moreover, rutile TiO2 is widely utilized in the production of plastics, inks, and paper, thanks to its excellent dispersibility and stability.

Anatase A Rising Star in Photocatalysis

Anatase, another crystalline form of titanium dioxide, has garnered considerable attention in recent years due to its unique photocatalytic properties. With a similar tetragonal structure but distinct electronic characteristics, anatase exhibits increased reactivity under UV light. This makes it ideal for applications in environmental remediation, self-cleaning surfaces, and water treatment processes.

china rutile vs anatase

In China, the interest in anatase TiO2 has surged due to its potential in the field of sustainable technology. As the nation grapples with severe pollution and environmental challenges, the photocatalytic capabilities of anatase are seen as a promising solution. Its high surface area-to-volume ratio enhances its catalytic efficiency, making it a popular choice for photocatalytic applications.

Notably, the production methods for anatase are similar to those for rutile, with the hydrothermal synthesis being a popular approach for nanoparticles. However, there is a rising trend toward developing more cost-effective and environmentally friendly manufacturing techniques, aligning with China's broader goals for sustainable industrial practices.

Comparative Properties and Applications

When comparing the two forms of titanium dioxide, one can observe key differences. Rutile demonstrates superior mechanical strength and thermal stability, which are critical for coatings and construction materials. In contrast, anatase's high activity under UV illumination provides distinct advantages in environmental applications.

In terms of pigment applications, rutile is favored for higher opacity and gloss, making it suitable for paints used in exterior applications. Conversely, anatase is increasingly recognized in specialized applications where photocatalytic activity is essential, such as in the development of self-cleaning materials and air purification systems.

Conclusion

Both rutile and anatase titanium dioxide exhibit unique properties that make them suitable for various applications. Rutile's dominance in pigment production and stability in adverse conditions contrast with anatase's rising significance in photocatalysis and environmental applications. As China continues to navigate its rapid industrialization and address environmental issues, the roles of these two forms of titanium dioxide will likely evolve.

In summary, while rutile and anatase share the common foundation of titanium dioxide, their differing characteristics and applications illustrate the complexity and versatility of this material in meeting both industrial and environmental needs. Understanding these differences is essential for stakeholders in the titanium dioxide market as they adapt to changing demands and strive for innovation.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025