Sep . 25, 2024 18:47 Back to list

china micronized titanium dioxide

The Relevance of Micronized Titanium Dioxide in China’s Industrial Landscape

In recent years, the growth of the Chinese economy has ushered in a heightened awareness of material science, particularly in the field of micronized titanium dioxide. This substance, a pigment derived from titanium, has garnered attention due to its exceptional properties, which include brightness, opacity, durability, and resistance to UV light. The increasing demand for high-performance materials across various sectors underscores its significance in China and beyond.

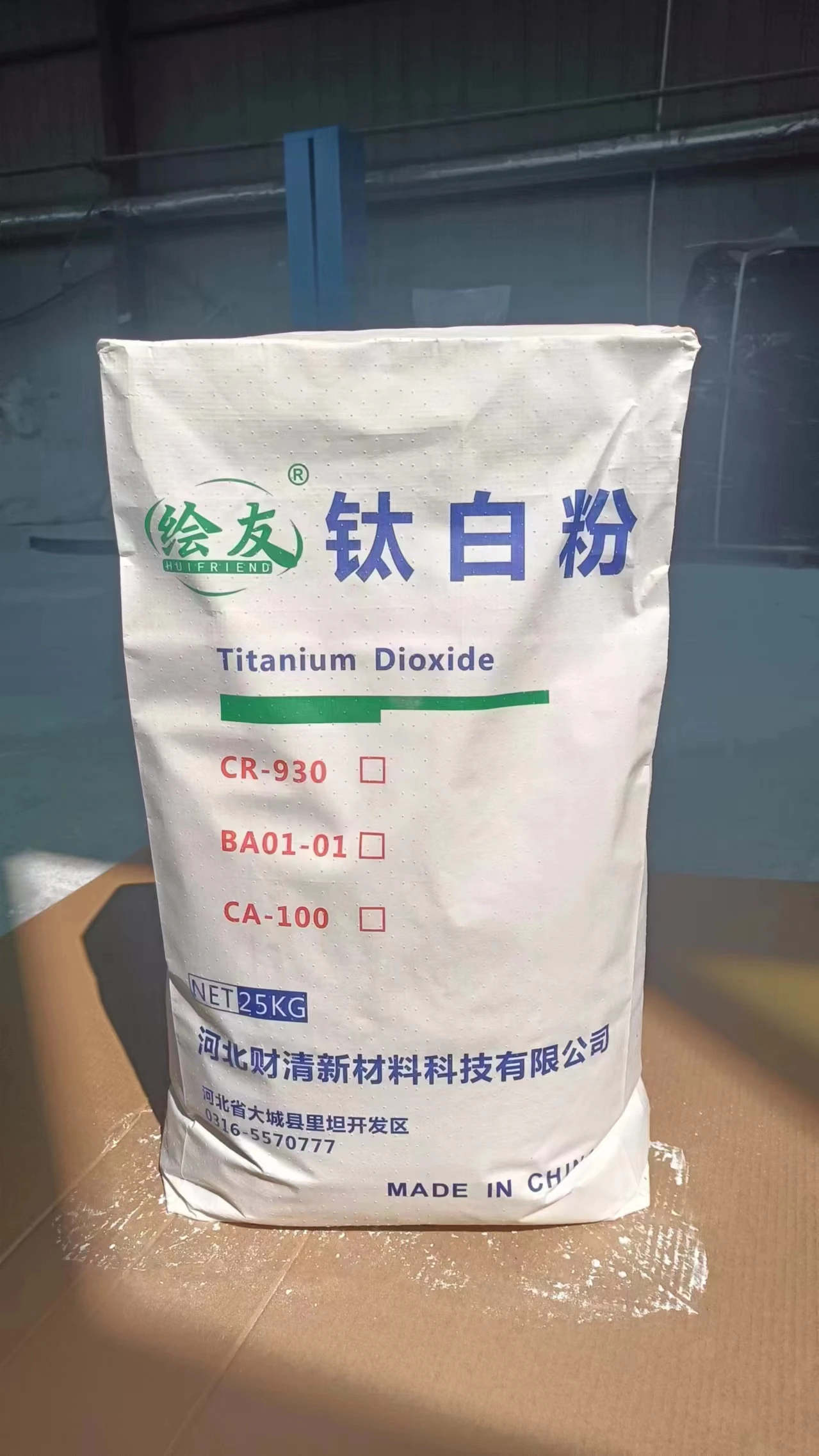

Micronized titanium dioxide is produced by grinding titanium dioxide (TiO2) into fine particles, enhancing its applicability across a wide range of industries, from coatings and plastics to cosmetics and pharmaceuticals. In China, a nation that has rapidly industrialized, this material is pivotal. The country boasts one of the largest manufacturing bases for titanium dioxide globally, responding to both domestic and international needs.

The Relevance of Micronized Titanium Dioxide in China’s Industrial Landscape

In plastics, the micronized form of titanium dioxide serves as a vital additive that imparts whiteness and opacity to products like packaging materials and automotive components. The automotive industry in China is booming, and with the government's push for electric vehicles and other advanced transportation means, the need for lightweight, durable materials is paramount. Titanium dioxide's ability to enhance the longevity and aesthetic appeal of plastic products serves as a key driver for its use in these applications.

china micronized titanium dioxide

Furthermore, the cosmetics industry has seen a rise in the formulation of products incorporating micronized titanium dioxide. Given its UV protection capabilities, many skincare and makeup products now include this pigment to safeguard users from harmful sun exposure. The growing consumer preference for safe and effective personal care products amplifies the significance of micronized titanium dioxide in this market, driving innovation and competition among manufacturers.

Notably, the environmental considerations surrounding the production and use of micronized titanium dioxide cannot be overlooked. As global awareness of sustainability rises, China is actively addressing the environmental impact of various industries. Manufacturers are increasingly adopting eco-friendly processes that minimize waste and energy consumption in the production of titanium dioxide. This movement aims to align with China’s broader goals of achieving carbon neutrality and promoting green manufacturing practices.

Innovation is at the core of the development of micronized titanium dioxide. Researchers and manufacturers are exploring advanced processing techniques to enhance performance characteristics and reduce costs. Nanotechnology and surface modification techniques are becoming instrumental for improving the dispersibility and effectiveness of titanium dioxide in various applications. Future advancements in this sector are poised to further broaden the scope of micronized titanium dioxide's applications.

Moreover, international trade dynamics significantly influence China's titanium dioxide market. As global demand for this substance escalates, China stands to benefit from export opportunities. Competing on the world stage necessitates that Chinese manufacturers produce high-grade micronized titanium dioxide that meets international quality standards. This not only bolsters domestic sectors but also positions China as a leading player in the global materials market.

In conclusion, micronized titanium dioxide represents a remarkable intersection of innovation, industrial growth, and sustainability in China. As diverse industries recognize its value, the demand for this versatile material continues to soar. With ongoing investments in research and development, along with a commitment to eco-friendly practices, the future of micronized titanium dioxide in China appears promising. As the nation seeks to reinforce its industrial capacity, the role of micronized titanium dioxide will undoubtedly expand, shaping the future of materials science and applications in the years to come.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025