Dec . 09, 2024 17:02 Back to list

Chemical Composition and Structure of Lithopone in China

Understanding Lithopone Chemical Composition and Applications

Lithopone is a white pigment that has historically held significant importance in the paint, coating, and plastics industries. Its chemical formula is primarily a combination of two compounds barium sulfate (BaSO4) and zinc sulfide (ZnS). The unique properties of lithopone make it a favorite among manufacturers looking for a high-quality white pigment.

Chemical Composition of Lithopone

The core composition of lithopone generally follows the formula

\[ \text{(ZnS) } \cdot \text{(BaSO}_4\text{)} \]

This combination typically contains about 30% zinc sulfide and 70% barium sulfate. The production of lithopone involves the precipitation of zinc sulfide in a process that typically requires barium ions. This reaction can be summarized as follows

1. Precipitation of Zinc Sulfide - Zinc sulfate (ZnSO4) reacts with sodium sulfide (Na2S) to produce zinc sulfide \[ \text{ZnSO}_4 + \text{Na}_2\text{S} \rightarrow \text{ZnS} + \text{Na}_2\text{SO}_4 \]

2. Addition of Barium Sulfate - Barium sulfate is either added directly or produced simultaneously, enhancing the overall luminosity and coverage of the pigment.

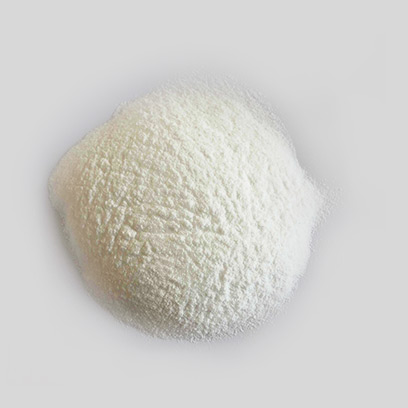

The resultant lithopone is a fine white powder, characterized by its exceptional covering power, durability, and resistance to fading when exposed to light.

Properties of Lithopone

Lithopone exhibits several striking properties that make it highly desirable as a pigment

1. Opacity and Brightness - Lithopone provides an excellent degree of opacity, ensuring that it effectively covers underlying colors and substrates. Its brightness is another significant attribute, resulting in a pleasing aesthetic for end products.

china chemical formula of lithopone

2. Chemical Stability - Unlike some white pigments, lithopone is chemically stable and does not react with other substances, making it suitable for use in various mixtures and formulations.

3. Lightfastness - Lithopone offers good resistance to photochemical degradation, ensuring that products maintain their appearance over time even under prolonged exposure to sunlight.

4. Non-Toxicity - As opposed to other white pigments, such as lead-based compounds, lithopone is considered relatively non-toxic and is often preferred in applications where safety is a priority.

Applications

The broad spectrum of lithopone's applications is a testament to its favorable properties. Here are some of the key areas where lithopone is utilized

1. Paints and Coatings - Lithopone is widely used in interior and exterior paints, primers, and varnishes, where it acts as a white pigment enhancing coverage and finish.

2. Plastics - The plastic industry employs lithopone to provide whiteness and opacity to products, ensuring an attractive appearance while maintaining strength.

3. Rubber - In rubber formulations, lithopone serves as a filler and pigment, integrating seamlessly while improving durability and visual characteristics.

4. Cosmetics - Due to its non-toxic nature, lithopone finds applications in cosmetics, including face powders and sunscreens, where a white pigment is often necessary.

Conclusion

In summary, lithopone stands out as a versatile and functional white pigment due to its unique chemical composition combining barium sulfate and zinc sulfide. Its favorable properties, such as excellent opacity, lightfastness, and non-toxic nature, have led to its widespread adoption across various industries, including paints, plastics, and cosmetics. As the demand for high-quality pigments continues to grow, lithopone remains a staple choice for manufacturers striving to enhance their products' aesthetic and functional qualities. Understanding the chemical formula and properties of lithopone is essential for those looking to harness its capabilities in their applications.

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025