Aug . 20, 2024 08:25 Back to list

China Rutile Titanium Dioxide MBR9668 for Advanced Coatings and Applications

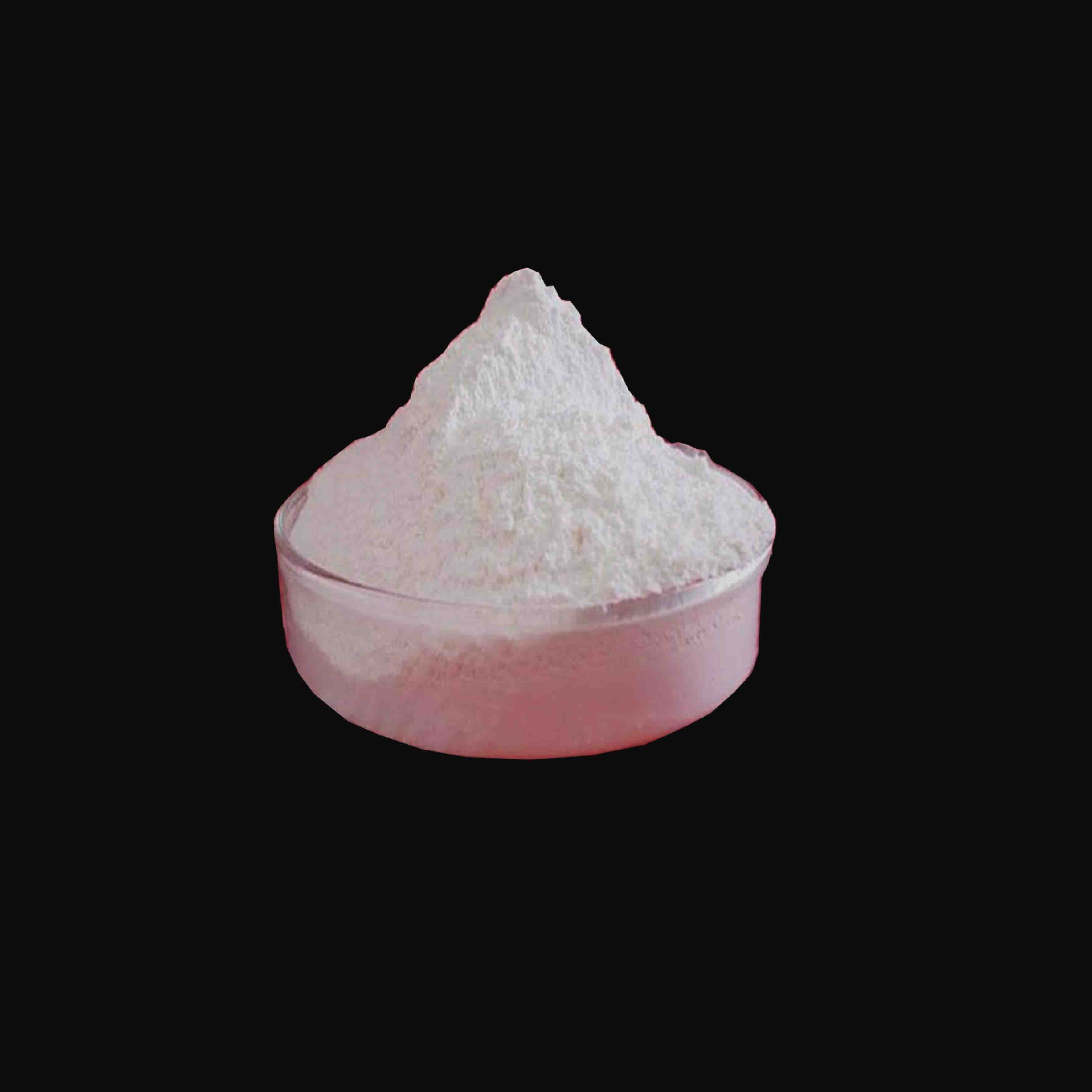

Exploring China Rutile Titanium Dioxide MBR9668 Coating

Rutile titanium dioxide (TiO₂) serves as one of the most important materials in various industrial applications, widely recognized for its superior opacity, brightness, and UV resistance. Among the diverse grades of titanium dioxide, MBR9668 has emerged in the spotlight due to its unique properties and advantages, particularly within the coatings sector. As industries evolve, the demand for high-performance coatings that meet stringent environmental regulations has grown, making MBR9668 a compelling choice for manufacturers.

Properties and Composition

MBR9668 is a type of rutile titanium dioxide that boasts an outstanding combination of physical and chemical properties. Its high refractive index contributes to excellent light reflection, which enhances the brightness and opacity of coatings. The rutile structure is particularly valued over anatase because of its superior weather resistance and durability, providing long-lasting protection against environmental factors.

Moreover, MBR9668 is engineered to have a controlled particle size and surface treatment, optimizing its dispersibility in various formulations. This tailored particle design not only enhances its compatibility with different resin systems but also improves the overall mechanical properties of the coatings. As a result, manufacturers can achieve a smoother finish, better adhesion, and enhanced durability in their products.

Applications in Coatings

The applications of MBR9668 in coatings are extensive. From decorative paints to industrial coatings, the pigment is utilized to create products that exhibit remarkable performance. Due to its excellent UV resistance, MBR9668 is often employed in exterior coatings that require longevity and protection against sunlight degradation.

china rutile titanium dioxide mbr9668-coating

In automotive coatings, MBR9668 contributes to the aesthetic appeal of vehicles while providing a robust protective layer. The pigment’s ability to enhance color brilliance and stability under various environmental conditions makes it a preferred choice for manufacturers aiming to elevate the visual quality and durability of their automotive finishes.

Additionally, MBR9668’s properties are advantageous in architectural and protective coatings, where durability and resistance to weathering are crucial. Coatings infused with MBR9668 can withstand harsh conditions while maintaining their color fidelity and structural integrity over time.

Environmental Considerations

In recent years, there has been a significant shift towards sustainable practices in manufacturing. MBR9668 aligns with these efforts as it is free from hazardous materials such as lead and cadmium, making it a safer choice for both users and the environment. The coatings formulated with MBR9668 not only comply with international safety standards but also contribute to the environmental sustainability initiatives that many companies are prioritizing.

As manufacturers seek to reduce their ecological footprint, the use of MBR9668 can be a strategic move. Its efficient performance allows for lower application thicknesses while maintaining high opacity, ultimately reducing the quantity of materials required for effective coverage. This reduction can lead to less waste generation and better resource utilization—key factors in promoting sustainability.

Conclusion

In conclusion, MBR9668 rutile titanium dioxide represents a significant advancement in the coatings industry, offering a multitude of benefits that cater to modern manufacturing demands. With its excellent opacity, brightness, durability, and environmental friendliness, it has become a preferred choice for manufacturers looking to enhance their products’ performance while adhering to sustainability goals. As industries continue to innovate, the role of MBR9668 will likely expand, paving the way for new applications and advancements in coating technologies. The future of coatings looks bright with materials like MBR9668 leading the charge towards excellence.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025