Sep . 21, 2024 17:01 Back to list

cas no.13463-67-7 titanium dioxide factory

Titanium Dioxide (CAS No. 13463-67-7) Manufacturing An Overview

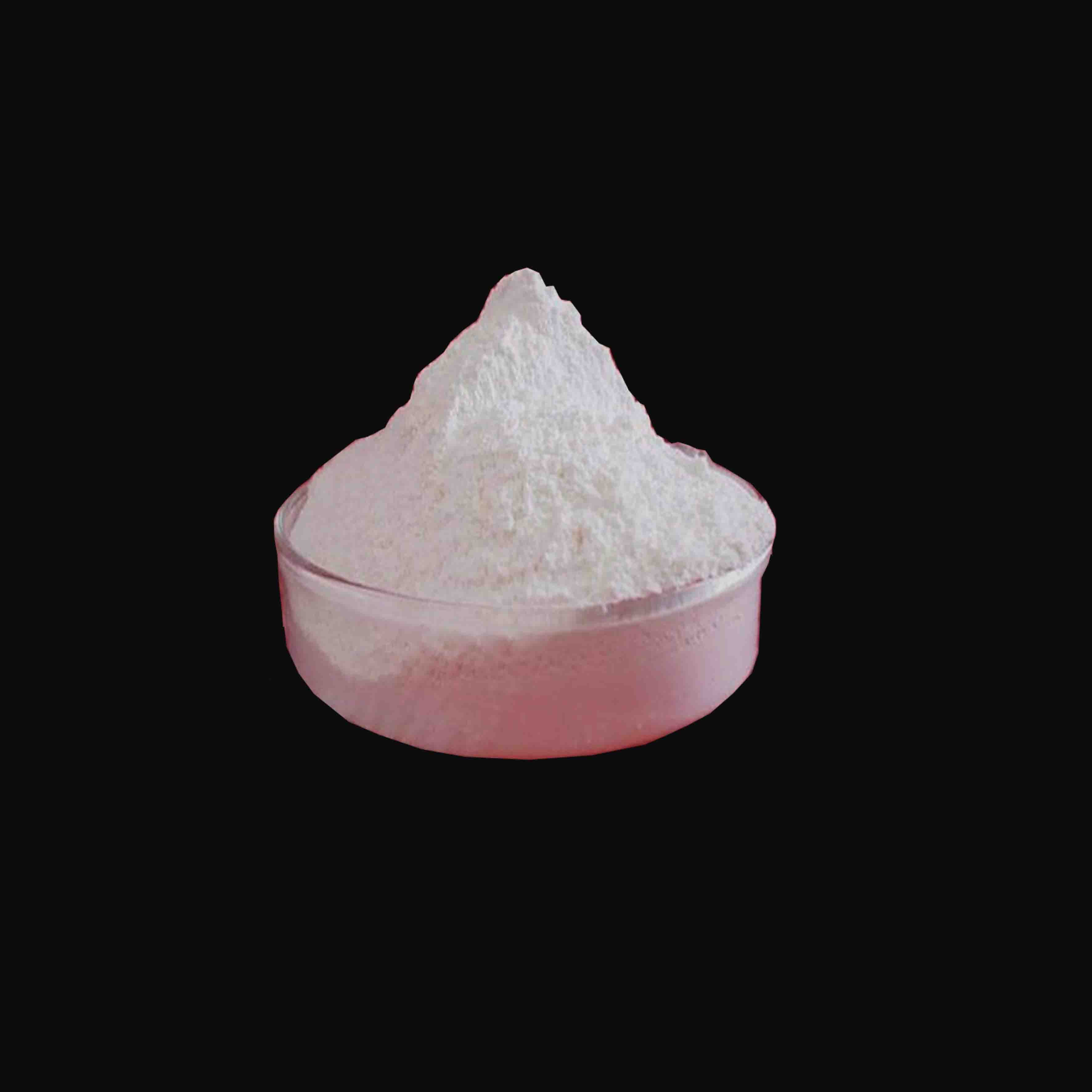

Titanium dioxide, identified by its Chemical Abstracts Service (CAS) number 13463-67-7, is a widely used white pigment known for its brightness and high refractive index. It is primarily utilized in various industries, including paints, coatings, plastics, paper, food, and cosmetics. The manufacturing of titanium dioxide is a significant sector due to the compound's versatility and essential role in enhancing product quality.

Production Process

The production of titanium dioxide typically involves two main processes the sulfate process and the chloride process

.1. Sulfate Process This traditional method involves the reaction of titanium ore (usually ilmenite) with sulfuric acid. The process results in the formation of titanium sulfate, which is then hydrolyzed to produce titanium dioxide. This method generates a considerable amount of waste and often includes the production of iron sulfate as a by-product.

2. Chloride Process In contrast, the chloride process is more modern and environmentally friendly. It begins with the chlorination of titanium ores, primarily rutile, in the presence of carbon at high temperatures to produce titanium tetrachloride (TiCl4). This compound is then oxidized to yield titanium dioxide. This method is favored for its efficiency and lower environmental impact, as it produces fewer by-products and waste.

cas no.13463-67-7 titanium dioxide factory

Applications

Titanium dioxide is renowned for its ability to provide opacity, brightness, and durability to products. In the paint and coatings industry, it serves as a key component, enhancing UV resistance and providing excellent coverage. In plastics, it helps in achieving better thermal and UV stability. Moreover, in cosmetics, titanium dioxide is often utilized as a pigment and sunblock agent due to its safety and efficacy.

Environmental Considerations

While titanium dioxide is a valuable compound, the manufacturing processes can pose environmental challenges. The sulfate process, in particular, can produce significant waste and pollutants. Therefore, many manufacturers are shifting towards the more sustainable chloride process, which reduces waste production and minimizes the environmental footprint. Additionally, efforts are ongoing to develop more sustainable raw material sourcing and recycling methods to enhance the overall sustainability of titanium dioxide production.

Conclusion

With diverse applications across multiple industries, titanium dioxide (CAS No. 13463-67-7) holds a vital position in modern manufacturing. As industries evolve and prioritization of sustainability escalates, the future of titanium dioxide production is likely to see significant advancements in eco-friendly practices and technologies. By adopting more sustainable processes, manufacturers can maintain the substance's essential role while addressing environmental concerns, ensuring its continued relevance in the marketplace.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025