Dec . 03, 2024 23:12 Back to list

Manufacturer Information for CAS No. 13463-67-7 and Its Applications in Industry

Understanding Titanium Dioxide Manufacturer Insights based on CAS No. 13463-67-7

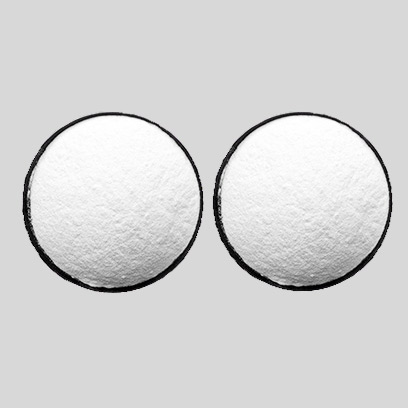

Titanium dioxide, identified by the CAS number 13463-67-7, is a naturally occurring oxide of titanium known for its bright white pigment and opacity. It has become a crucial component in a wide array of applications, ranging from paints and coatings to plastics, food products, and cosmetics. As industries increasingly seek high-performance and sustainable materials, understanding the manufacturing processes and standards surrounding titanium dioxide becomes increasingly important.

Manufacturing Process of Titanium Dioxide

The production of titanium dioxide typically follows two primary methods the sulfate process and the chloride process

.1. Sulfate Process This traditional method involves the digestion of titanium ore, usually ilmenite, with sulfuric acid. The process results in the formation of titanium sulfate, which can then be hydrolyzed to produce titanium dioxide. This method often generates a significant amount of waste products and can be less environmentally friendly compared to the chloride process.

2. Chloride Process This method has gained popularity due to its more efficient and environmentally friendly nature. In this process, titanium tetrachloride (TiCl4) is produced by reacting titanium ore with chlorine at high temperatures. The TiCl4 is then oxidized to produce titanium dioxide through a high-temperature reaction with oxygen. This method not only reduces waste but also yields a purer product with better performance characteristics.

Global Manufacturers and Market Insights

The global demand for titanium dioxide is primarily driven by the coatings and plastics market. Leading manufacturers are continuously investing in research and development to enhance production efficiency and reduce environmental impacts. Companies such as The Chemours Company, Tronox Limited, and Huntsman Corporation are among the key players in titanium dioxide production, employing advanced technologies to optimize their processes.

cas no.13463-67-7 manufacturer

Furthermore, manufacturers are facing increasing pressure to meet stringent environmental regulations. This has led to innovations in cleaner production techniques, including the adoption of closed-loop systems to minimize waste and energy consumption. The emphasis on sustainability is also pushing manufacturers to explore alternative feedstocks, thereby diversifying their supply chains and minimizing reliance on traditional ore sources.

Applications of Titanium Dioxide

Titanium dioxide is renowned for its versatility. In the paint and coatings industry, it serves not only as a pigment but also as a key ingredient for UV protection, improving the durability and weather resistance of products. The plastic industry utilizes titanium dioxide to enhance the opacity and brightness of products, ensuring a quality finish.

In the food industry, titanium dioxide is used as a coloring agent, approved by many regulatory bodies for use in various food items. Its safety profile, combined with its ability to impart whiteness and opacity, contributes to its popularity. However, recent discussions have emerged regarding its safety in food applications, prompting ongoing research and regulatory reviews.

Future Prospects

As the world leans toward sustainable practices, the titanium dioxide industry is also adapting to these changes. Innovations in production technologies, along with the development of bio-based alternatives and recycling strategies, are likely to shape the future of titanium dioxide manufacturing. With the growing emphasis on environmental sustainability and safety, the potential for titanium dioxide remains robust, ensuring its relevance across multiple industries for years to come.

In conclusion, the titanium dioxide market is dynamic, with advancements in manufacturing processes influencing its applications and environmental impact. Understanding the role of major manufacturers and their commitment to sustainability will continue to shape the future of this vital compound identified by CAS No. 13463-67-7.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025