Oct . 31, 2024 15:55 Back to list

Explore Top Manufacturers for Quality Lithopone Products Available for Purchase

The Role of Lithopone in Modern Manufacturing and the Market for Lithopone Suppliers

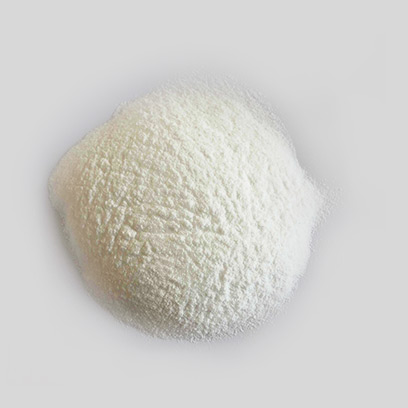

Lithopone, a white pigment composed of barium sulfate and zinc sulfide, has garnered significant attention in various industries due to its unique properties and versatility. Its use as a pigment in paints, coatings, plastics, and even in cosmetics highlights its importance. As industries increasingly prioritize quality and performance, the demand for high-quality lithopone from reputable manufacturers has significantly grown.

Characteristics and Applications of Lithopone

Lithopone is known for its excellent opacity and brightness, making it a preferred choice for manufacturers looking to enhance the quality of their products. Its ability to resist yellowing and its stability under UV light give it an edge over other pigments. This makes it particularly valuable in the paint and coatings industry, where durability and aesthetic appeal are paramount.

Beyond paints, lithopone is widely used in plastics, where it acts as a filler and enhances the product's overall quality. The cosmetic industry has also embraced lithopone, using it in formulations for products such as sunscreen and makeup, where its pigmenting properties are crucial for achieving the desired appearance and protection levels.

The Growing Demand for Quality Lithopone

Given the diverse applications of lithopone, the demand for high-quality products has led to an influx of manufacturers aiming to supply this crucial pigment. Companies are increasingly looking for lithopone suppliers that can provide consistent quality, competitive pricing, and reliable delivery. Quality control is paramount, as the properties of lithopone can directly impact the end product's performance.

buy lithopone manufacturers

Manufacturers focusing on producing lithopone with high purity levels and optimal particle size are particularly sought after. The ability to customize products to meet specific industry requirements further enhances a supplier's appeal. As industries evolve, they seek suppliers that not only provide lithopone but also offer expertise in technical support and innovation.

Finding Reliable Lithopone Manufacturers

When searching for lithopone manufacturers, buyers should consider several key factors to ensure they partner with reputable suppliers. Quality certifications, such as ISO standards, can be a good indicator of a manufacturer’s commitment to quality. Additionally, seeking out manufacturers with a proven track record in the industry can provide reassurance.

Furthermore, engaging with manufacturers who possess the capability for research and development can be advantageous. These suppliers can work collaboratively with clients to innovate and improve formulations, thereby enabling mutual growth and product enhancement.

The Future of Lithopone Supply

As the industries that utilize lithopone continue to grow, the future of lithopone manufacturing looks promising. Innovations in production processes and a focus on sustainability are likely to shape the market dynamics. Companies that can leverage technology to enhance production efficiency while maintaining quality will be well-positioned for success.

In conclusion, the market for lithopone is evolving, with an increasing emphasis on quality and performance. Manufacturers looking to buy lithopone must navigate a landscape populated with various suppliers, emphasizing reliability and expertise. By prioritizing quality and innovation, buyers can ensure they are making informed decisions that will benefit their operations in the long term.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025