Jul . 26, 2024 00:12 Back to list

Barium Sulfate Particle Size Specifications and Options from Various Manufacturing Companies

Barium Sulfate Particle Size Importance and Manufacturers

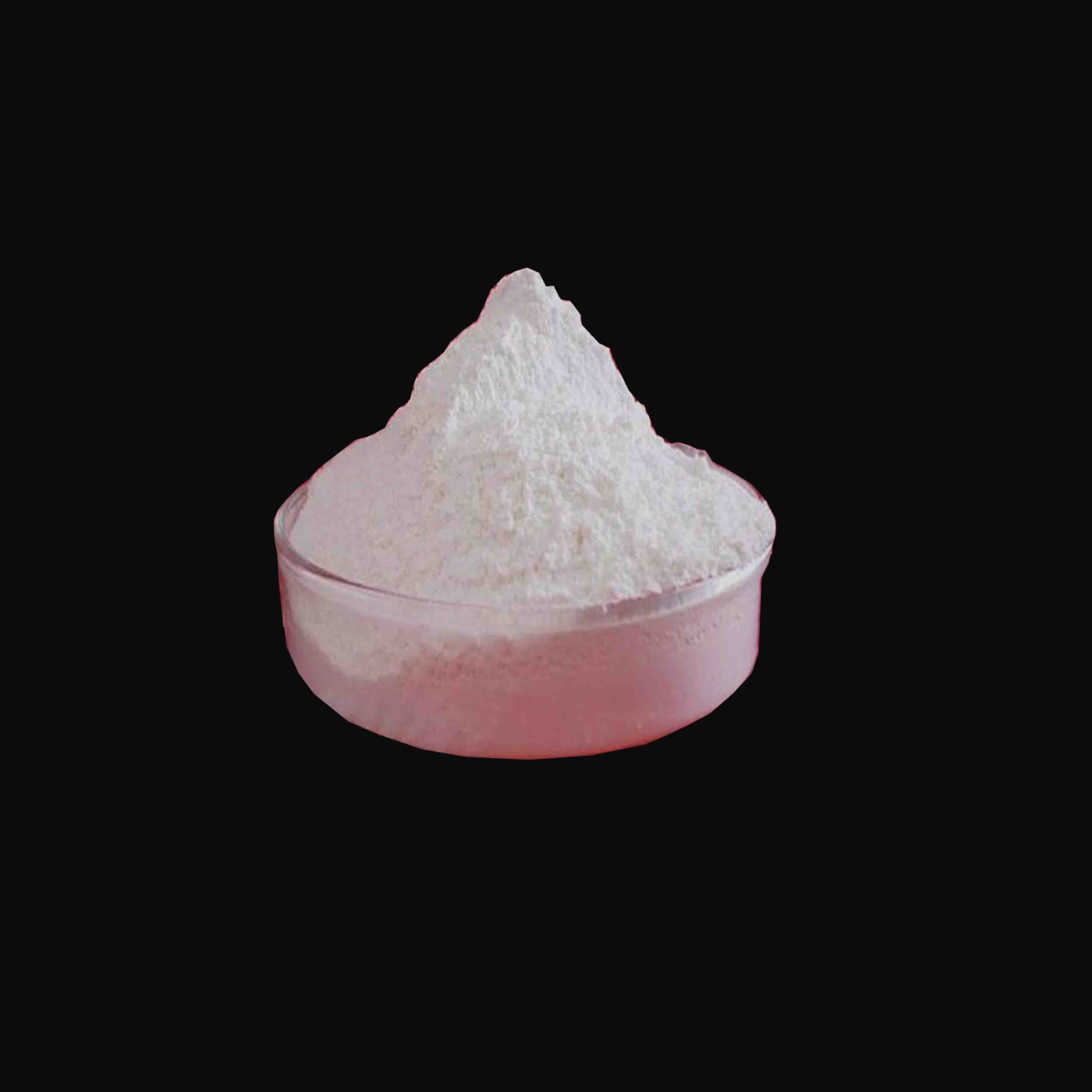

Barium sulfate (BaSO4) is a widely used inorganic compound with applications across diverse industries, such as pharmaceuticals, paints, plastics, rubber, and environmental applications. One of the critical factors that influence the performance of barium sulfate in these applications is its particle size. The particle size of barium sulfate affects its opacity, brightness, and dispersion properties, making it essential for manufacturers to carefully control the production process.

Importance of Particle Size

The particle size of barium sulfate can significantly impact its functionality. In the paint and coatings industry, for example, finer particles provide better hiding power and opacity. This is crucial for achieving a uniform finish and ensuring that the underlying substrate is effectively masked. In pharmaceuticals, the particle size can influence the drug's bioavailability. Smaller particles develop larger surface areas, which can enhance the dissolution rates, leading to improved absorption in the body.

In plastics and rubber, the particle size affects the mechanical properties of the finished product, such as tensile strength, flexibility, and durability. Finer barium sulfate particles can improve the overall performance of these materials while maintaining their lightweight characteristics.

Manufacturing Processes

Different manufacturers employ various methods to produce barium sulfate with specific particle sizes. The most common production techniques include precipitation, grinding, and surface modification.

1. Precipitation Method This is one of the most widely used methods to produce fine barium sulfate particles. It involves the reaction between barium ions (from barium chloride or barium nitrate) and sulfate ions (usually from sodium sulfate or sulfuric acid) in an aqueous solution. The resulting barium sulfate precipitate can be filtered and washed to remove impurities. By controlling the reaction conditions—such as temperature, concentration, and stirring speed—manufacturers can achieve a desired particle size distribution.

2. Grinding Process After precipitation, the barium sulfate can undergo milling or grinding to achieve a finer particle size. Various grinding techniques, including ball milling, jet milling, and impact milling, can be employed. Each technique has its own advantages and is selected based on the desired end product properties.

barium sulfate particle size manufacturers

3. Surface Modification In some applications, it may be necessary to modify the surface of barium sulfate particles to enhance their compatibility with various resins and polymers. Surface treatments can help improve dispersibility, enhance stability, and reduce aggregation, leading to better performance in the final application.

Key Manufacturers

Several companies are renowned for producing high-quality barium sulfate with controlled particle sizes. These manufacturers often invest in advanced technologies and strict quality control measures to ensure consistency and performance in their products.

1. BASF A global leader in chemical production, BASF offers a variety of barium sulfate grades tailored for different applications. Their products are known for superior quality and consistent particle size distribution.

2. Schillers Aggregates This company specializes in producing high-purity barium sulfate. They focus on precise manufacturing processes and offer both fine and coarse grades to meet specific customer needs.

3. Solvay Another prominent player in the chemicals market, Solvay produces barium sulfate with excellent mechanical properties and is used in various industrial applications.

Conclusion

In conclusion, the particle size of barium sulfate is a critical factor that directly influences its performance across various industries. Manufacturers must carefully control production methods to achieve the desired particle size, ensuring optimal functionality for the end-user applications. With the continued demand for high-quality barium sulfate, manufacturers who focus on innovation and consistency in particle size will remain competitive in the marketplace.

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025