Aug . 12, 2024 05:54 Back to list

Applications of Titanium Dioxide in Plastic Industry and Its Impact on Product Performance

The Role of Titanium Dioxide in Plastics A Closer Look at China's Use

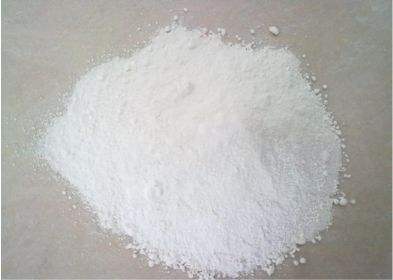

Titanium dioxide (TiO2) has gained significant attention in various industries due to its unique properties, particularly its brightness, opacity, and ultraviolet (UV) resistance. One of the most notable applications of TiO2 is its use in plastics, where it enhances both performance and aesthetics. In recent years, China has emerged as a key player in the global market for TiO2, reflecting the increasing demand for high-quality plastic products across diverse sectors.

TiO2 is widely utilized as a pigment to impart whiteness and opacity to plastic materials. Its high refractive index and strong covering power make it an ideal choice for products requiring bright, vibrant colors. In the plastic industry, TiO2 is commonly added to items ranging from packaging materials to consumer goods, automotive components, and construction materials. The addition of TiO2 not only improves the visual appeal of these products but also enhances their durability and longevity by providing a protective barrier against UV radiation.

The Role of Titanium Dioxide in Plastics A Closer Look at China's Use

The Chinese government has also been proactive in promoting the use of advanced materials, including TiO2, to enhance the quality of its manufacturing capabilities. This includes supporting research and development initiatives aimed at discovering new applications for TiO2 in plastics and improving its production processes. Additionally, as environmental regulations become more stringent, manufacturers are increasingly turning to TiO2 as a safer and more sustainable option compared to traditional pigment materials.

china tio2 used in plastic

Moreover, the versatility of TiO2 extends beyond aesthetic purposes. Its photocatalytic properties make it an effective agent for self-cleaning and anti-bacterial applications in plastics. This characteristic is particularly valuable in consumer products, where hygiene and ease of maintenance are paramount. For instance, TiO2-treated surfaces in kitchenware or medical devices can decompose organic matter upon exposure to sunlight, providing a significant advantage for everyday consumers.

Despite the numerous benefits associated with TiO2, there are concerns regarding its safety, particularly in relation to its nanoparticle form. Ongoing research is necessary to fully understand the health impacts of TiO2 exposure in both humans and the environment. The Chinese government, alongside industry stakeholders, is committed to ensuring that TiO2 usage adheres to safety standards, helping to mitigate potential risks while still reaping the advantages of this versatile compound.

Furthermore, as the global market begins to shift towards more environmentally friendly options, China is exploring sustainable practices in TiO2 production. This includes moving towards more eco-friendly sourcing of raw materials and implementing cleaner production methods, thereby reducing the overall carbon footprint associated with TiO2 manufacturing.

In conclusion, titanium dioxide plays a crucial role in the plastic industry, particularly in China, where its application has expanded significantly. With its ability to enhance quality, durability, and aesthetics of plastic products, TiO2 continues to be in high demand as the country strengthens its position in the global market. As research progresses and sustainability becomes more central to manufacturing processes, the future looks promising for the continued use of titanium dioxide in plastics, paving the way for innovation and environmental responsibility.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025