Dec . 11, 2024 10:31 Back to list

Producers of Anatase Titanium Dioxide in the Global Market and Their Manufacturing Insights

An Overview of Anatase Titanium Dioxide Producers and Their Factories

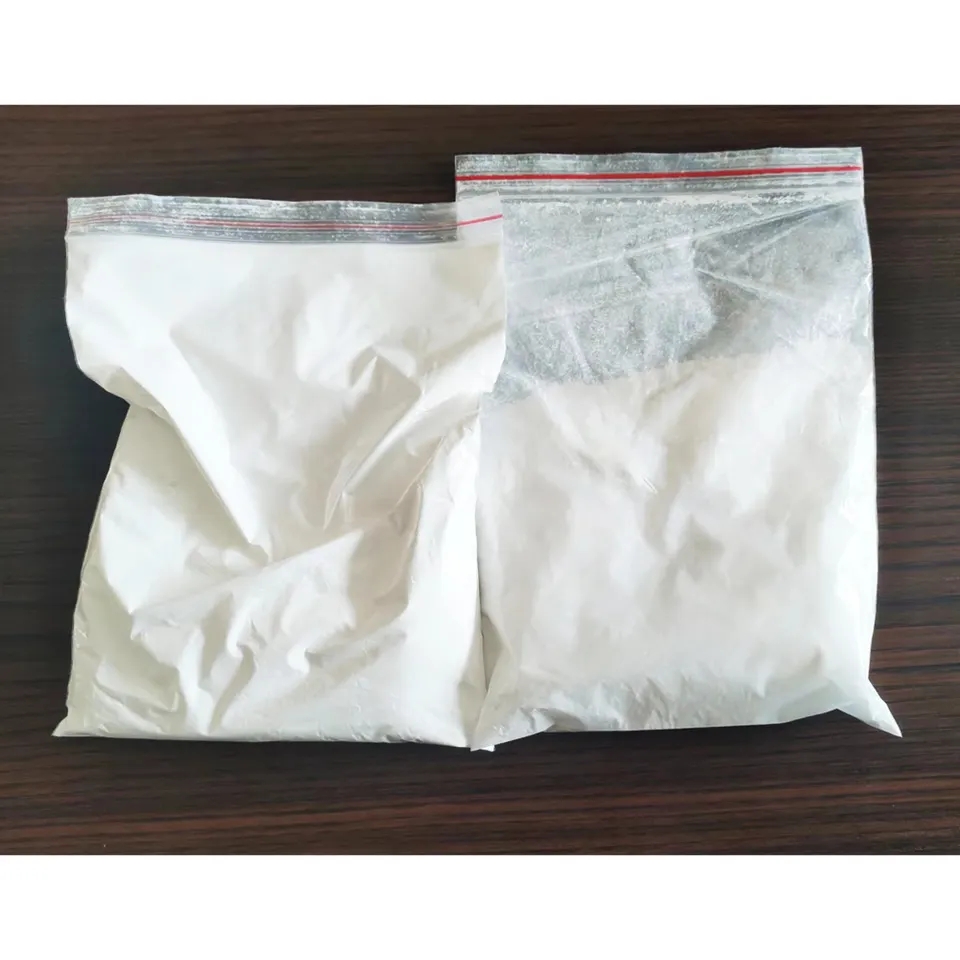

Anatase titanium dioxide (TiO2) is a significant material in various industries, including paints, coatings, plastics, and cosmetics. Renowned for its high refractive index and excellent opacity, anatase TiO2 is favored for applications that require bright, durable finishes. This article delves into the production of anatase titanium dioxide, the key players in the market, and the factory processes that ensure the quality and efficiency of this essential pigment.

The Significance of Anatase Titanium Dioxide

Anatase TiO2 is one of the three crystal structures of titanium dioxide, the others being rutile and brookite. Among these, anatase is particularly valued for its superior photocatalytic properties, making it useful in self-cleaning surfaces, water treatment, and as a UV filter in sunscreens. It is also popular in the cosmetic industry due to its ability to provide a white, bright appearance without compromising the texture of the product.

Key Players in the Market

The market for anatase titanium dioxide is comprised of several major producers, each with their own unique selling propositions and technological advancements. Companies like Tronox, Chemours, and Huntsman are among the leading manufacturers in the titanium dioxide industry. They are strategically located across different parts of the globe to cater to regional demands while optimizing logistics for raw materials and final products.

These manufacturers invest heavily in research and development to improve the quality of their products, reduce production costs, and minimize environmental impact. Each company's facility is equipped with state-of-the-art technology for the production of anatase TiO2, employing processes that ensure the crystalline structure, particle size, and surface treatment of the pigment meet the specific demands of their customers.

Production Process of Anatase Titanium Dioxide

anatase titanium dioxide producers factory

The production of anatase titanium dioxide typically involves several steps, with the most common methods being the sulfate process and the chloride process. Each method has its advantages and disadvantages, influencing the choice of process based on the intended application of the TiO2 produced.

1. Sulfate Process This traditional method begins with the extraction of ilmenite ore, which contains titanium dioxide. The ore is treated with sulfuric acid, resulting in a slurry of titanium sulfate. Through hydrolysis, titanium dioxide is precipitated and then calcined to produce anatase TiO2. While this method is well-established and cost-effective, it generates significant waste byproducts, requiring efficient waste management systems in factories.

2. Chloride Process In contrast, the chloride process is a more environmentally friendly and modern approach to producing TiO2. Titanium tetrachloride (TiCl4) is produced by reacting titanium oxide with chlorine and carbon at high temperatures. This TiCl4 is then oxidized to form TiO2. Factories employing the chloride process boast lower waste generation and higher purity of the final product, appealing to manufacturers of high-performance applications.

Innovations and Environmental Considerations

As environmental regulations tighten and sustainability becomes a priority, anatase titanium dioxide producers are continuously exploring innovations to enhance their production processes. This includes advancing filtration methods, recycling waste materials, and developing eco-friendly additives to reduce the environmental footprint of their operations.

Furthermore, new applications of anatase TiO2 in photocatalysis and environmental remediation are opening additional markets for producers. Factories are adapting to these trends by investing in new technologies that expand the functionality of their products. For example, the integration of nanotechnology in TiO2 production can enhance its properties, making it suitable for advanced applications in energy and electronics.

Conclusion

The production of anatase titanium dioxide is a vital component of many industries, influencing the quality and performance of a wide range of products. With market leaders continuously evolving their processes and products, the future of anatase TiO2 looks promising. As factories adopt more sustainable practices and innovative technologies, they not only enhance their operational efficiencies but also contribute to a greener future, meeting the demands of a conscious consumer base. The interplay between production methods, market needs, and environmental stewardship will continue to shape the landscape of anatase titanium dioxide manufacturing in the years to come.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025