Sep . 19, 2024 13:34 Back to list

anatase paints inks coating masterbatch factories

The Role of Anatase in Paints, Inks, and Coatings A Guide for Masterbatch Factories

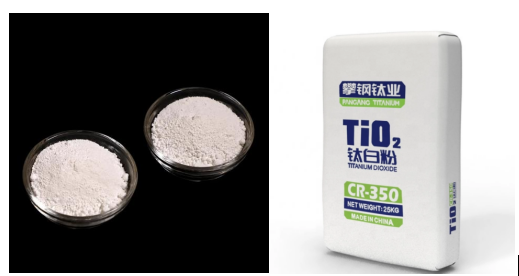

Anatase, one of the most significant polymorphs of titanium dioxide (TiO2), holds a prominent position in the manufacturing of paints, inks, and coatings

. Its unique properties make it an essential ingredient for masterbatch factories, contributing to the quality and performance of a wide range of products.First and foremost, anatase is known for its excellent pigmentary properties. It provides a brilliant whiteness and contributes to opacity, making it an ideal choice for formulations that require high coverage. In the paint industry, anatase enhances the brightness and color fidelity of various shades, allowing manufacturers to achieve vibrant hues that stand out. Its ability to scatter light effectively results in an impressive visual appeal, which is crucial for consumer products, from residential paints to industrial coatings.

Moreover, anatase is recognized for its outstanding durability and resistance to UV degradation. This is particularly advantageous for outdoor applications, as coatings containing anatase can withstand harsh environmental conditions without fading or losing their integrity. This long-lasting performance not only extends the life of the products but also aligns with the growing demand for sustainable and durable solutions in the coatings industry.

anatase paints inks coating masterbatch factories

In addition to its pigmentation and durability, anatase demonstrates photocatalytic properties. When exposed to UV light, it can accelerate chemical reactions, making it effective in self-cleaning applications and improving air quality. This characteristic is being explored in coatings that can decompose organic matter and pollutants, thus contributing to environmentally friendly products.

For masterbatch factories, understanding the various forms and manufacturing processes of anatase is critical. The choice between anatase and its rutile counterpart often depends on the desired characteristics of the end product. While rutile titanium dioxide offers higher opacity, anatase presents unique benefits that can enhance the formulation of specific paints and coatings. Consequently, masterbatch producers are tasked with developing innovative solutions that meet the unique demands of their clients while leveraging the advantages of anatase.

With the increasing emphasis on sustainability and eco-friendly products, incorporating anatase into paints and coatings aligns with industry trends. As businesses strive to reduce their environmental footprint, the photocatalytic properties of anatase can serve as a cornerstone for developing sustainable formulations that not only perform well but also contribute positively to the environment.

In conclusion, anatase plays a pivotal role in the manufacture of paints, inks, and coatings, particularly within masterbatch factories. Its superior pigmentary properties, durability, and innovative photocatalytic effects make it an invaluable ingredient for creating high-quality, sustainable products. As the industry continues to evolve, the demand for effective and environmentally friendly solutions will likely propel the use of anatase to new heights.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025