Dec . 11, 2024 22:50 Back to list

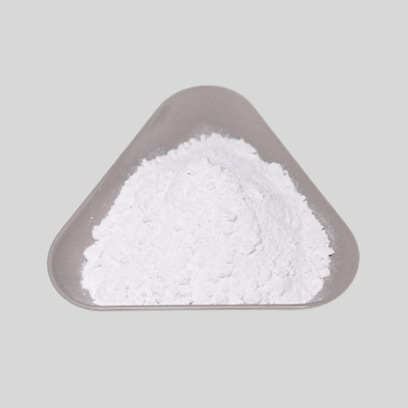

High-Purity 98% Min Anatase Titanium Dioxide Production Facilities and Processes

The Significance of 98% Min Titanium Dioxide Anatase Factories

Titanium dioxide (TiO2) is one of the most important materials in modern industrial applications. Notably utilized for its remarkable properties, titanium dioxide is prevalent in various sectors, including paints, coatings, plastics, food, and cosmetics. Among its three crystal forms—rutile, anatase, and brookite—anatase titanium dioxide has garnered increasing attention. Factories specializing in the production of 98% min titanium dioxide anatase play a crucial role in meeting global demand and supporting various industries.

Understanding Titanium Dioxide and Its Forms

Titanium dioxide is renowned for its high refractive index and strong ultraviolet (UV) light absorbing capabilities. This makes it an exceptional white pigment, enhancing opacity and brightness in products. Anatase, characterized by its tetragonal crystal structure, is particularly valued for its photocatalytic properties, making it suitable for applications such as air purification and self-cleaning surfaces. Its enhanced surface area and reactivity compared to rutile make it a preferred choice for many applications, including environmental remediation and solar energy conversion.

The Process of Production in Factories

The production of 98% min titanium dioxide anatase involves several sophisticated steps. Raw materials, including titanium feedstock, are subjected to a series of chemical processes. The primary methods for producing anatase TiO2 include the sulfate process and the chloride process. The sulfate process involves the reaction of titanium ores with sulfuric acid, while the chloride process utilizes titanium tetrachloride produced from the reaction of titanium ores with chlorine gas.

In factories aiming to produce high-purity anatase TiO2, stringent quality control measures are essential. The final product must meet or exceed the 98% purity threshold, indicating minimal contamination and a high concentration of active titanium dioxide. Facilities often employ advanced techniques such as X-ray fluorescence, particle size analysis, and dynamic light scattering to ensure the quality and consistency of the end product.

Applications and Market Demand

98%min titanium dioxide anatase factories

The demand for high-purity anatase titanium dioxide is surging across multiple sectors. In the paint and coatings industry, its application enhances the durability and longevity of products. The construction industry benefits from its use in producing self-cleaning surfaces, which contribute to less maintenance and longer-lasting structures. Additionally, the photocatalytic properties of anatase TiO2 contribute to environmental applications, including water treatment and air purification.

The increase in environmental awareness has driven the demand for photocatalytic materials, further emphasizing the need for specialized anatase factories. With stricter regulations regarding emissions and environmental pollutants, the role of TiO2 in creating cleaner technologies is more critical than ever.

Economic Impact and Industrial Growth

The establishment and operation of 98% min titanium dioxide anatase factories have significant economic implications. These factories create jobs, stimulate local economies, and attract investment. Countries that invest in advanced manufacturing technologies for titanium dioxide are positioning themselves as leaders in the global market, as demand continues to rise.

Moreover, the growth of high-purity titanium dioxide production enhances a country’s trade capabilities. Nations that excel in manufacturing this essential material can export it to industries across the globe, thereby boosting their economic stability and growth.

Conclusion

The significance of 98% min titanium dioxide anatase factories cannot be understated. As a critical resource in various sectors, the production of high-purity TiO2 supports advancements in technology, environmental sustainability, and industrial growth. With ongoing research and development, coupled with increasing environmental awareness, these factories are poised to play an instrumental role in shaping the future of titanium dioxide applications. The significant advancements in production methods and technologies ensure that the industry will continue to evolve, meeting the demands of an ever-changing global market.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025